Road asphalt modifier containing direct coal liquefaction residue, modified road asphalt, and preparation methods of road asphalt modifier and modified road asphalt

A technology for direct coal liquefaction and road asphalt, which is used in building components, building insulation materials, buildings, etc., can solve the problems of high softening point and low temperature brittleness of direct coal liquefaction residues, avoid aging, improve dispersion effect, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Although the road asphalt modifier obtained by mixing the above components evenly can have better performance than the prior art, preferably, according to the second aspect of the present invention, the preparation of the road asphalt modifier provided by the present invention The method includes the following steps:

[0030] (1) Stir the petroleum heavy oil and the polymer at 30-200°C;

[0031] (2) Add coal to directly liquefy the residue, raise the temperature to 150-250°C, stir evenly and cool to obtain road asphalt modifier.

[0032] With respect to 100 parts by weight of the coal direct liquefaction residue, the content of petroleum heavy oil is 10-150 parts by weight, and the content of the polymer is 10-70 parts by weight. Preferably, relative to 100 parts by weight of coal direct liquefaction residue, the content of petroleum heavy oil is 12-120 parts by weight, and the content of polymer is 11-60 parts by weight; more preferably, relative to 100 parts by weigh...

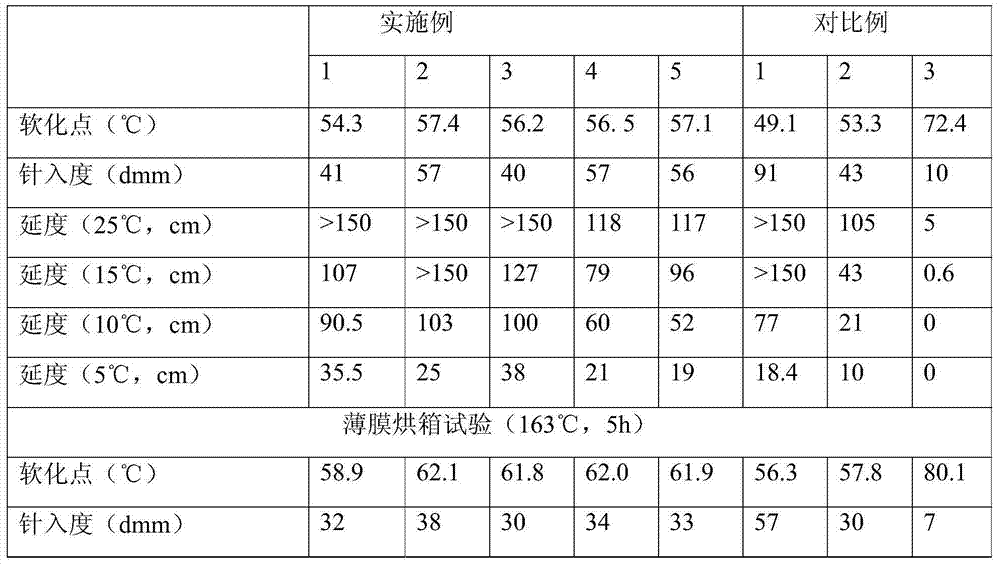

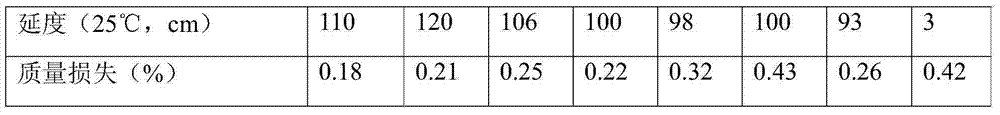

Embodiment 1

[0055] This embodiment is used to illustrate the road asphalt modifier and modified road asphalt provided by the present invention and the preparation method thereof.

[0056] The raw material ratio and method for preparing 1000g road modified asphalt are as follows:

[0057] 90g catalytic cracking oil slurry (produced by Yanshan Petrochemical, ρ 20℃ =0.985g / ml, the fraction greater than 350°C is 76% by weight, the freezing point is 10.2°C, and the kinematic viscosity at 100°C is 14.78mm 2 ·s -1 ) and 20g of SBR (SBR1712 produced by Fujian Petrochemical) were stirred and mixed for 2 hours at 60°C and 50rpm to obtain the first mixture. The mixture was cooled to obtain 200 g of the road asphalt modifier.

[0058] The above-mentioned road asphalt modifier was crushed into particles with a diameter of less than 5 mm, added to 800 g of 90# base road asphalt, and stirred and mixed at 150° C. at a speed of 500 rpm for 45 minutes to obtain modified road asphalt. The properties of ...

Embodiment 2

[0060] This embodiment is used to illustrate the road asphalt modifier and modified road asphalt provided by the present invention and the preparation method thereof.

[0061] The raw material ratio and method for preparing 1000g road modified asphalt are as follows:

[0062] 10g catalytic cracking oil slurry (produced by Yanshan Petrochemical, ρ 20℃ =0.985g / ml, the fraction greater than 350°C is 76% by weight, the freezing point is 10.2°C, and the kinematic viscosity at 100°C is 14.78mm 2 ·s -1 ) and 20g of SBR (SBR1712 produced by Fujian Petrochemical) were stirred and mixed for 3 hours at 50°C and 800rpm to obtain the first mixture. The mixture was cooled to obtain 100 g of the road asphalt modifier.

[0063] The above-mentioned road asphalt modifier was crushed into particles with a diameter of less than 5 mm, added to 900 g of 90# base road asphalt, and stirred and mixed at 100° C. at a speed of 200 rpm for 30 minutes to obtain modified road asphalt. The properties of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com