Road asphalt modifier and modified road asphalt, preparation method thereof and asphalt mixture

A road asphalt and modifier technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of large change of asphalt ductility with temperature, poor asphalt ductility at low temperature, poor stability of asphalt pavement, etc., and achieve high additional Value utilization and large-scale utilization problems, the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

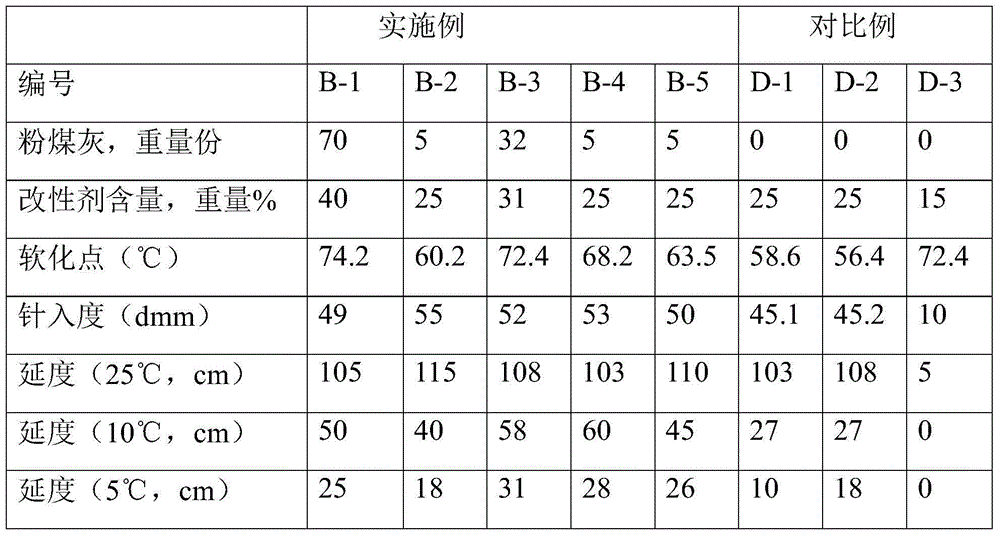

Examples

preparation example Construction

[0031] Although the road asphalt modifier obtained by mixing the above components evenly can have better performance than the prior art, but preferably, according to the second aspect of the present invention, a road asphalt modification provided by the present invention is provided The preparation method of the agent comprises: (1) heating the coal direct liquefaction residue, fly ash and water in the presence of an oxidizing agent, the heating temperature is 200-350°C, and the heating time is 15-120min; (2) Stir the petroleum heavy oil and the polymer at 30-200°C; (3) mix the residue obtained from the direct liquefaction of the modified coal obtained in the step (1) with the mixture obtained in the step (2), stir evenly and then cool to obtain road asphalt modified sex agent.

[0032] With respect to 100 parts by weight of the coal direct liquefaction residue, the content of heavy petroleum oil is 30-150 parts by weight, preferably, the content of heavy petroleum oil is 40-1...

Embodiment 1

[0053] This embodiment is used to illustrate the road asphalt modifier and modified road asphalt provided by the present invention and the preparation method thereof.

[0054] Road asphalt modifier:

[0055]1) Mix 100 parts by weight of coal direct liquefaction residue with 70 parts by weight of fly ash (average particle size of 5 μm, D95 particle size of 10 μm), add water, and heat at 250 ° C for 50 min in the presence of air. The humidity at the time is 95%RH, and then cooled to obtain the residue of direct liquefaction of modified coal;

[0056] 2) 140 parts by weight of catalytic cracking oil slurry (produced by Yanshan Petrochemical, ρ 20℃ =0.985g / ml, the content greater than 350°C distillation range is 76% by weight, the freezing point is 10.2°C, and the kinematic viscosity at 100°C is 14.78mm 2 ·s -1 ) and 20 parts by weight of SBR (SBR1712 produced by Fujian Petrochemical) were stirred and mixed for 2 hours at 60 ° C and 50 rpm to obtain a mixture;

[0057] 3) The ...

Embodiment 2

[0063] This embodiment is used to illustrate the road asphalt modifier and modified road asphalt provided by the present invention and the preparation method thereof.

[0064] Road asphalt modifier:

[0065] 1) Mix 100 parts by weight of coal direct liquefaction residue with 5 parts by weight of fly ash (average particle size of 4 μm, D95 particle size of 8 μm), add water, and heat at 200 ° C for 120 min in the presence of air. The humidity at the time is 85%RH, and then cooled to obtain the residue of direct liquefaction of modified coal;

[0066] 2) 50 parts by weight of catalytic cracking oil slurry (produced by Yanshan Petrochemical, ρ 20℃ =0.985g / ml, the content greater than 350°C distillation range is 76% by weight, the freezing point is 10.2°C, and the kinematic viscosity at 100°C is 14.78mm 2 ·s -1 ) and 20 parts by weight of SBR (SBR1712 produced by Fujian Petrochemical) were stirred and mixed for 3 hours at 50 ° C and 800 rpm to obtain a mixture;

[0067] 3) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com