Thermally dissolving and catalytic method for preparing liquid fuel by lignite as well as catalyst and solvent used therefor

A liquid fuel and catalyst technology, applied in the field of catalysts and solvents, can solve the problems of high technical requirements, harsh conditions and large investment, and achieve the effects of simple preparation equipment, mild operating conditions and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the circulating solvent is as follows: take part of the liquid product separated from step 4), and undergo two-stage hydrogenation, the first-stage hydrogenation temperature is 280-350°C, the second-stage hydrogenation temperature is 310-390°C, and the pressure is 6-13MPa. Hydrogen oil ratio 300~500(v / v), space velocity 0.2~1.2h -1 Under certain conditions, the solvent obtained is suitably hydrogenated. If the obtained solvent meets the following indicators: density 0.96~0.98g / l, distillation range 200~400°C, hydrogen content (m%) 7.6%~10%, then enter the step 2) coal slurry of the above method as a circulating solvent instead of anthracene oil In preparation; if the above indicators are not met, return to the circulating solvent preparation process for rehydrogenation. The catalysts required for the preparation of circulating solvents are general industrial oil hydrogenation catalysts such as the hydrogenation refining catalysts FRIPP3926 and...

Embodiment 1~7

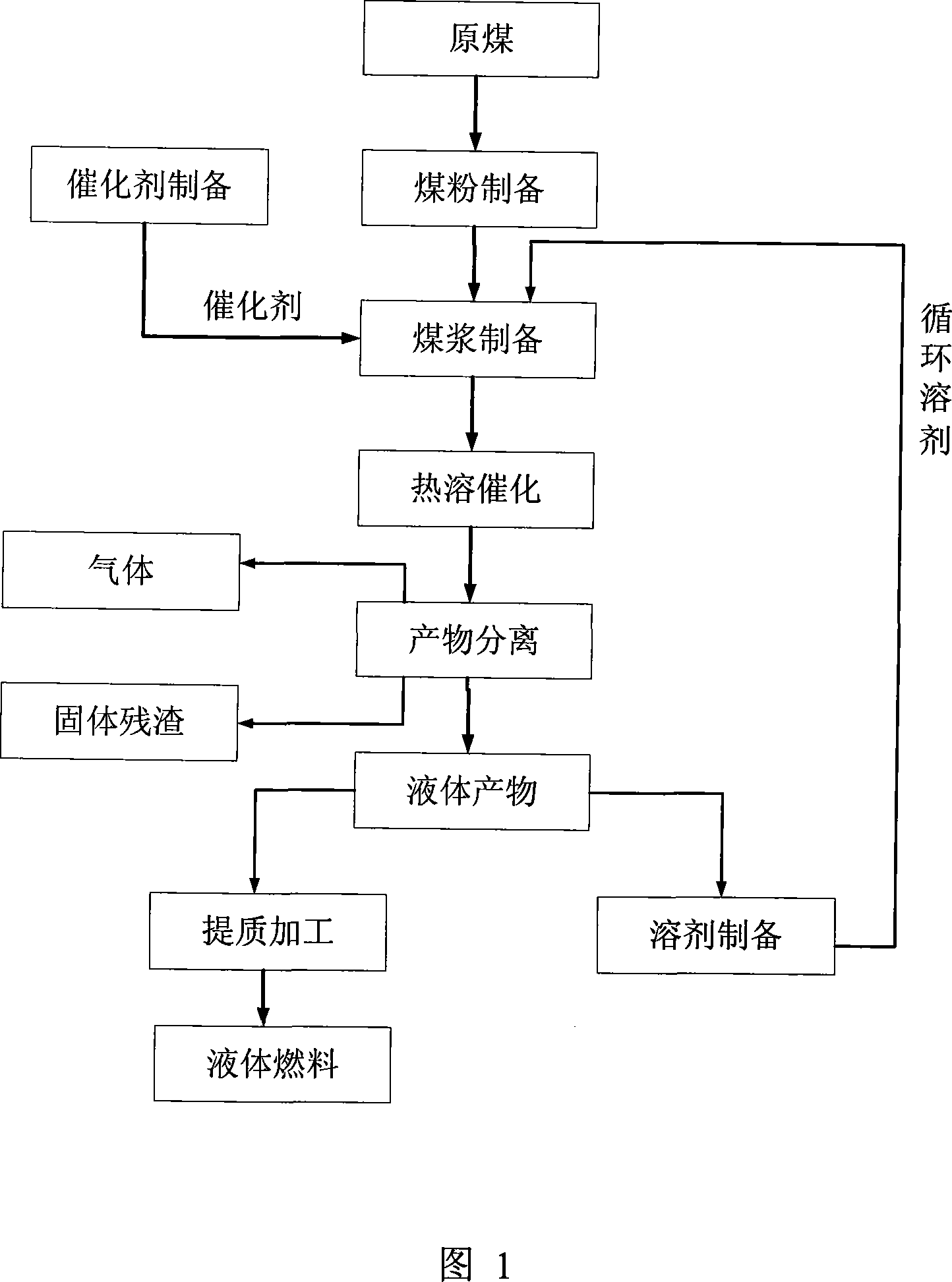

[0050] Put the pulverized and dried coal powder (80-200 mesh in particle size, 2%-5% moisture) and the circulating solvent generated by the method itself into the coal slurry tank according to the ratio required by the method and a certain amount of catalyst. The coal slurry used in the method is prepared through thorough stirring and mixing in the slurry preparation tank. The coal slurry is sent to the hot-melt catalytic reactor, and the reaction is carried out under the liquefaction condition of the method. The reaction material from the reactor enters the separation device, and the three-phase material of gas, liquid and solid is separated. The gas is treated to meet the environmental protection requirements and enters the heating system as fuel gas; the solid is used as liquefied residue and enters the residue treatment system; liquid material Part of it enters the circulating solvent preparation device, and part of the circulating solvent required by the production method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com