Fireworks paper tube

A paper tube and fireworks technology, applied in the field of bottomless firework paper tube structure, can solve the problems of high cost and low efficiency of paper tubes, achieve good product quality, ensure product quality, and prevent the mud bottom of the inner tube from being damp and washed The effect of the cracked bottom paper tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

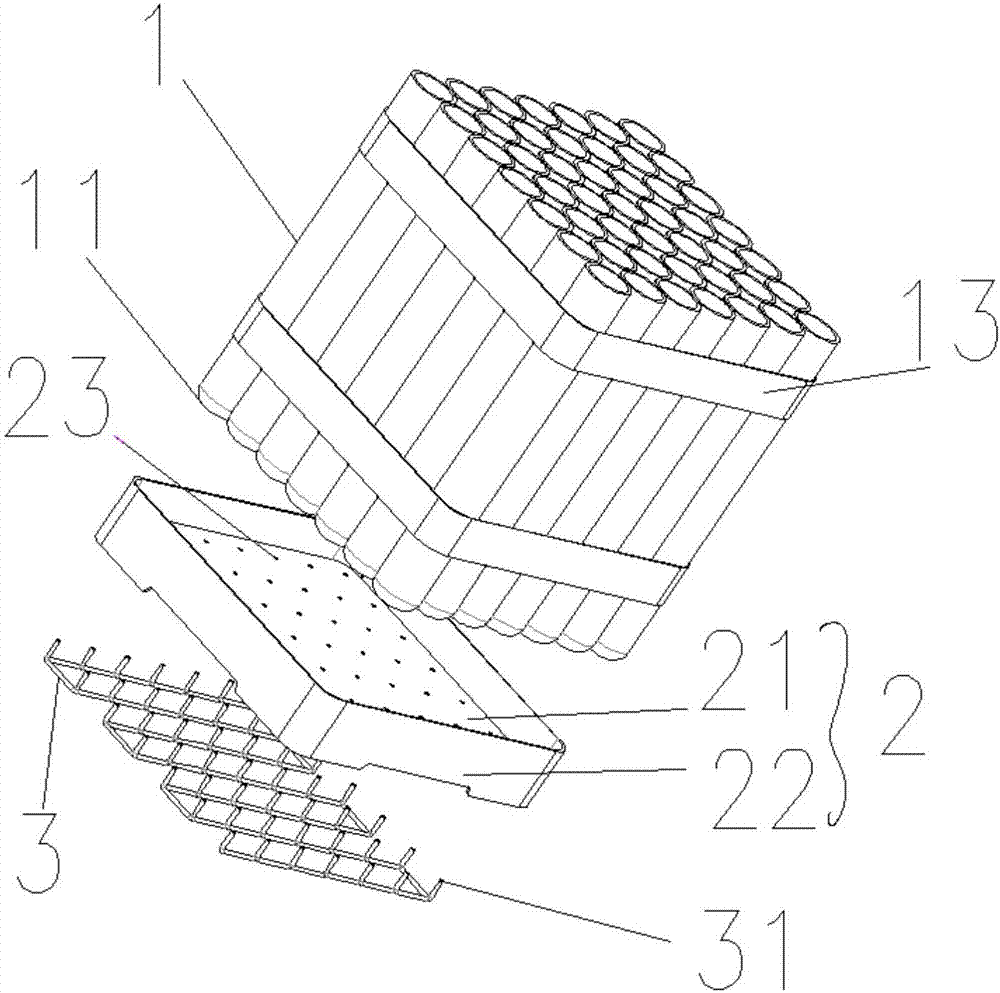

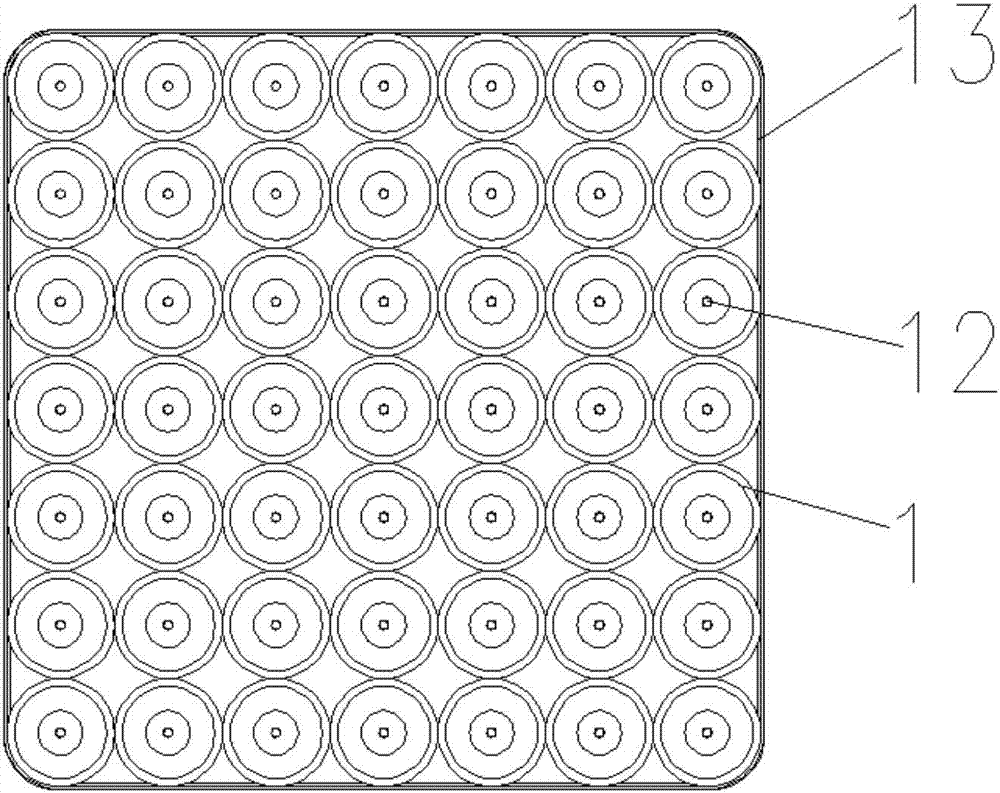

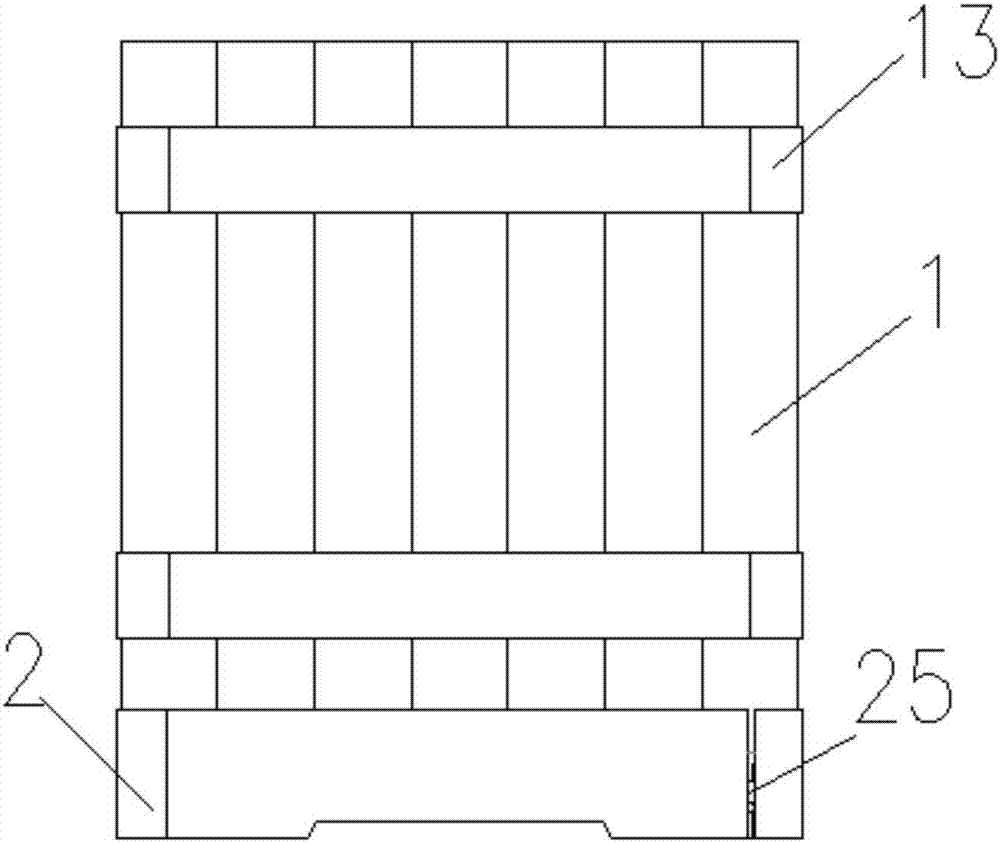

[0019] see Figure 1-4 , reflecting a preferred embodiment of the present invention, the fireworks paper tube includes a cylinder body composed of 7*7 array tubes 1, a base 2 arranged at the lower part of the cylinder body, and lead wires inserted on the base from the bottom 3. The diameter of the lead wire is 2-2.4 mm. The lead wire is inserted to form a lead post 31. One end of the single bobbin is open, and the other end is a bottom seal 11 with a glue layer, which is rotated and extruded by the bobbin itself Forming (firstly put the bottom end of the bobbin into the rubber basin to wet and soften, and then rotate and extrude through the rotary die), an adhesive layer is set between adjacent bobbins, and the bobbins are connected together through the adhesive layer to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com