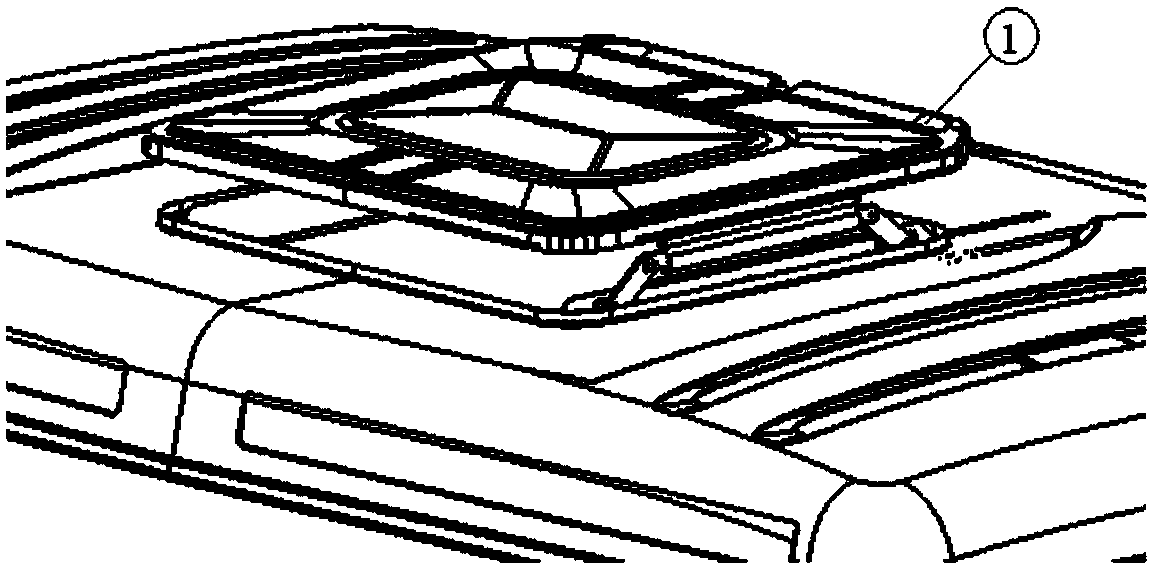

Heavy truck top cover assembly structure with rotating skylight device

A heavy-duty truck and assembly structure technology, applied in the field of vehicles, can solve the problems of installing a gun rack, unable to use the sunroof, and the sunroof cannot be rotated in all directions, and achieves the effect of flexible limit and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the accompanying drawings.

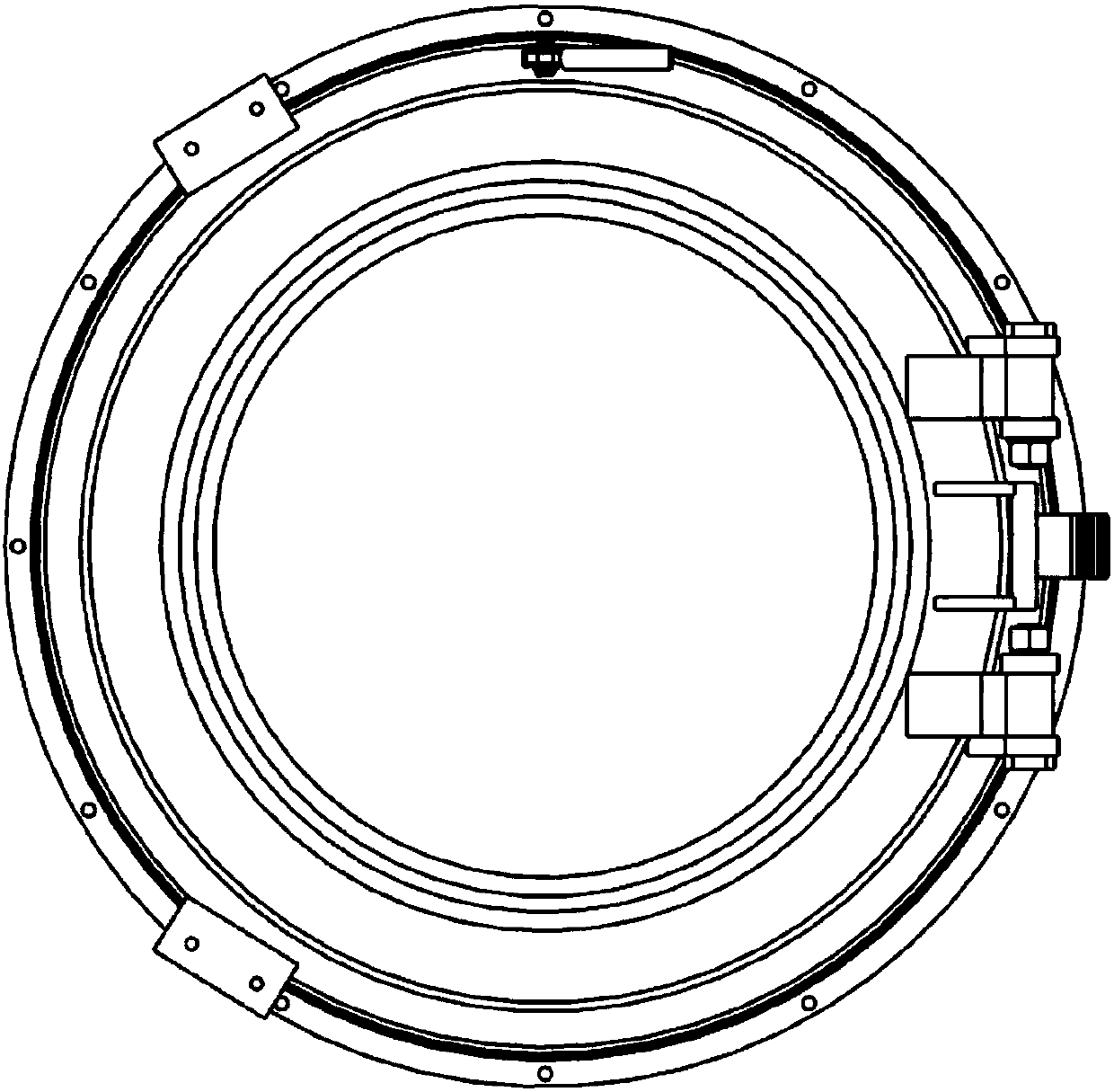

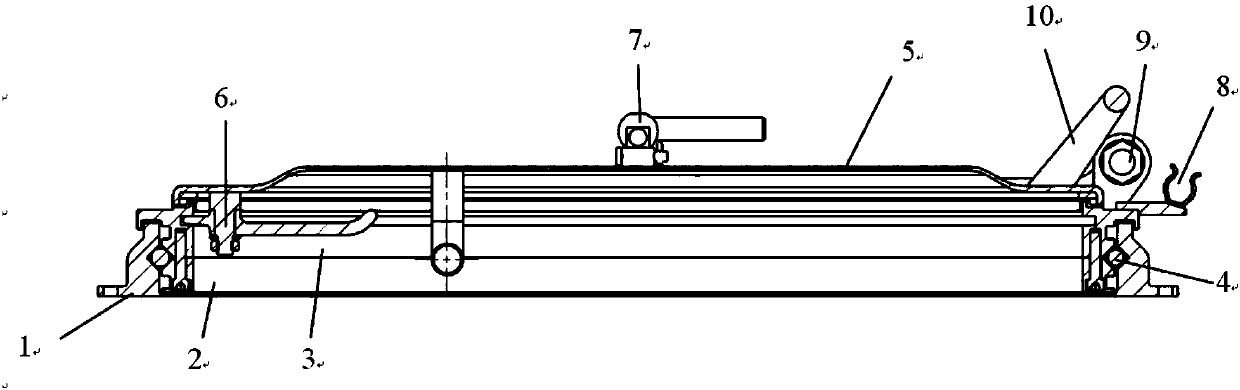

[0027] A structure of a heavy truck roof assembly with a rotating sunroof device of the present invention includes a rotating sunroof device and a roof assembly, wherein the rotating sunroof device includes a fixed ring 1, an upper moving ring 2, a lower moving ring 3, and a ball 4. , cover plate 5, handle opening mechanism 6, stop mechanism 7, positioning spring 8, hinge mechanism 9, positioning bracket 10, etc.; as attached figure 2 It is a top view of the rotating sunroof device with attached image 3 A half-section view of the rotating sunroof unit is shown.

[0028] Among them, the upper moving ring 2 and the lower moving ring 3 are connected by bolts to form a first V-shaped structure and a fixed ring with a second V-shaped structure for accommodating the balls 4 to be fixed as a whole. The first V-shaped structure and the second V-shaped structure are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com