Vertical spinning machine for tank of cement tanker

A technology of cement tanker and spinning machine, applied in the field of spinning machine, can solve the problems of increasing the weight of the car body, reducing the load of the vehicle, complex process, etc., and achieve the effect of good overall quality, reduced manufacturing process, and good spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

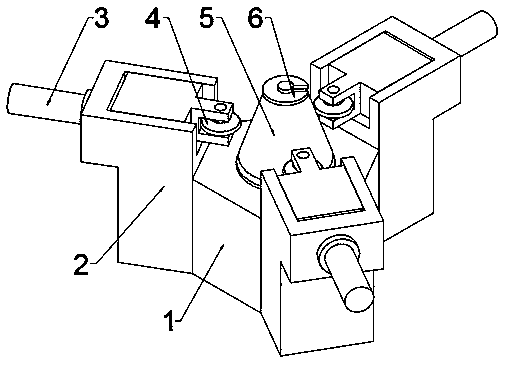

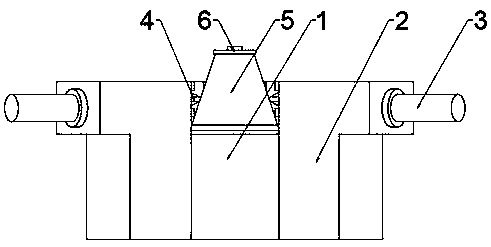

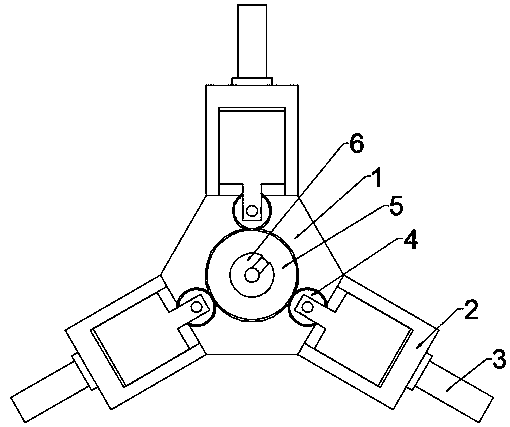

[0018] Example 1: Please refer to Figure 1-3 , a vertical spinning machine for a tank body of a cement tanker, comprising a frame 1, a spinning device 2 is evenly distributed on the side of the frame 1, and the spinning device 2 is connected to the side of the frame 1 by sliding up and down, and the spinning device 2 The upper part is slidably connected with a rotary wheel 4 through a hydraulic rod 3, and the moving direction of the hydraulic rod 3 is toward the middle of the frame 1; the inner side of the frame 1 is connected with a fixing mechanism through a rotating drive mechanism.

[0019] There are three spinning devices 2, which are distributed on the side of the frame 1 at 120°.

[0020] The fixing mechanism includes a mold 5 and a fixing plate 6 .

[0021] The fixed disk 6 is U-shaped.

Embodiment 2

[0022] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the driving mechanism is a motor with high transmission efficiency.

[0023] The working principle of the present invention is: the device is a three-wheel hydraulic spinning machine, the central spindle rotates, the hydraulic cylinder in the center of the spindle presses the workpiece through the U-shaped disc, and the three rotary wheels 4 sequentially spin down the workpiece to make the workpiece thinner Stretching, while the blank is rotating with the main shaft of the bed, pressurize the blank with the rotary wheel 4 to make it produce local plastic deformation of the pressure tank head. Under the joint action of the feed motion of the rotary wheel 4 and the rotation motion of the blank, the local plastic deformation is gradually extended to the entire surface of the blank, and it is closely attached to the mold 5 to complete the spinning process of the part. The advantage of spinnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com