Back row seat

A technology for rear seats and seats, which is applied in the direction of seat frames, vehicle seats, special positions of vehicles, etc., can solve the problems of inconvenient loading and unloading of rear seats, small weight of rear seats, etc., and achieve Lightweight design, increased strength, and improved connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

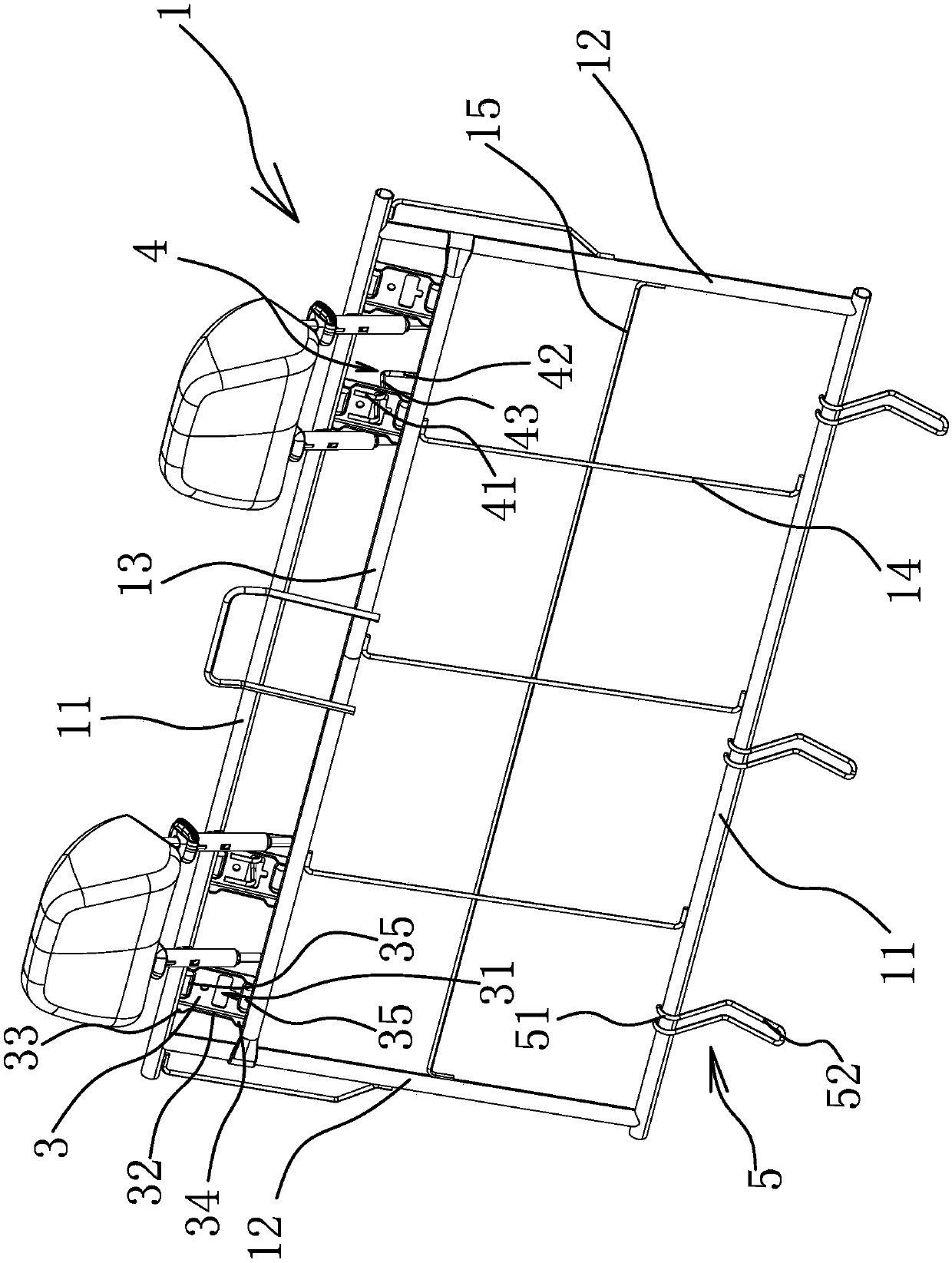

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

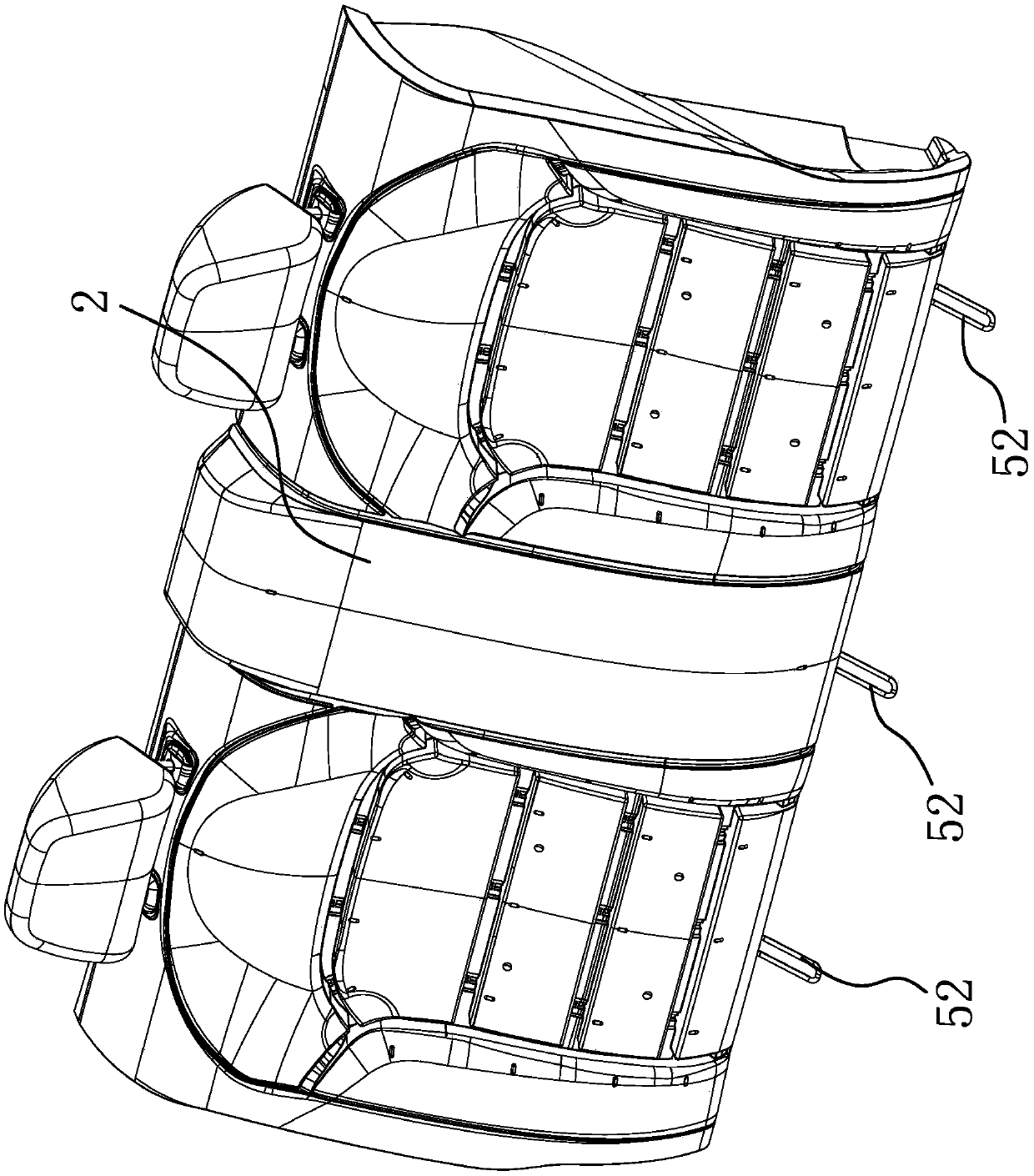

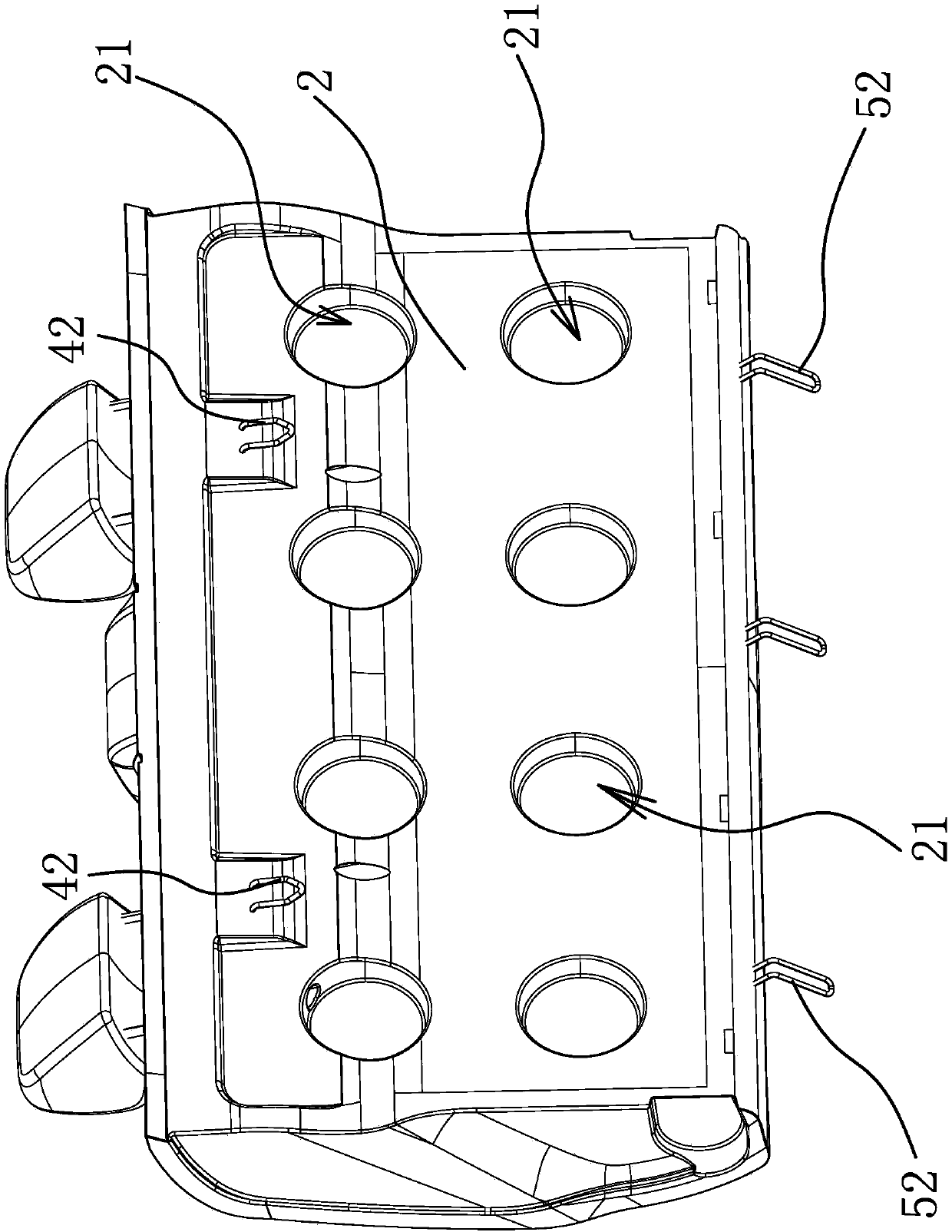

[0034] Such as figure 1 As shown, the rear seat comprises a support frame 1 and a seat cushion body 2, and the support frame 1 is in a frame shape.

[0035] Specifically, if Figure 1-6 As shown, the support frame 1 is embedded in the seat cushion body 2, the support frame 1 includes two horizontal tubes 11 and two vertical tubes 12, the two vertical tubes 12 are located between the two horizontal tubes 11, and the two horizontal tubes 11 Installing pipe 13 is arranged between, and the two ends of installing pipe 13 are connected with two vertical pipes 12 respectively, and positioning plate 3 is arranged between installing pipe 13 and the horizontal pipe 11 near the upper end of support frame 1, and setting plate 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com