Efficient energy-saving environment-friendly resin plate for diamond wire cutting silicon wafer and degumming method

A diamond wire cutting, high-efficiency and energy-saving technology, applied in the field of solar photovoltaic power generation, can solve the problems of reducing the speed of the table, closing the knife at the tail for about 40 minutes, increasing the pressure of environmental protection treatment, and waste of equipment utilization, so as to reduce the overall resin board Model weight, saving cleaning time efficiency, and improving the utilization rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

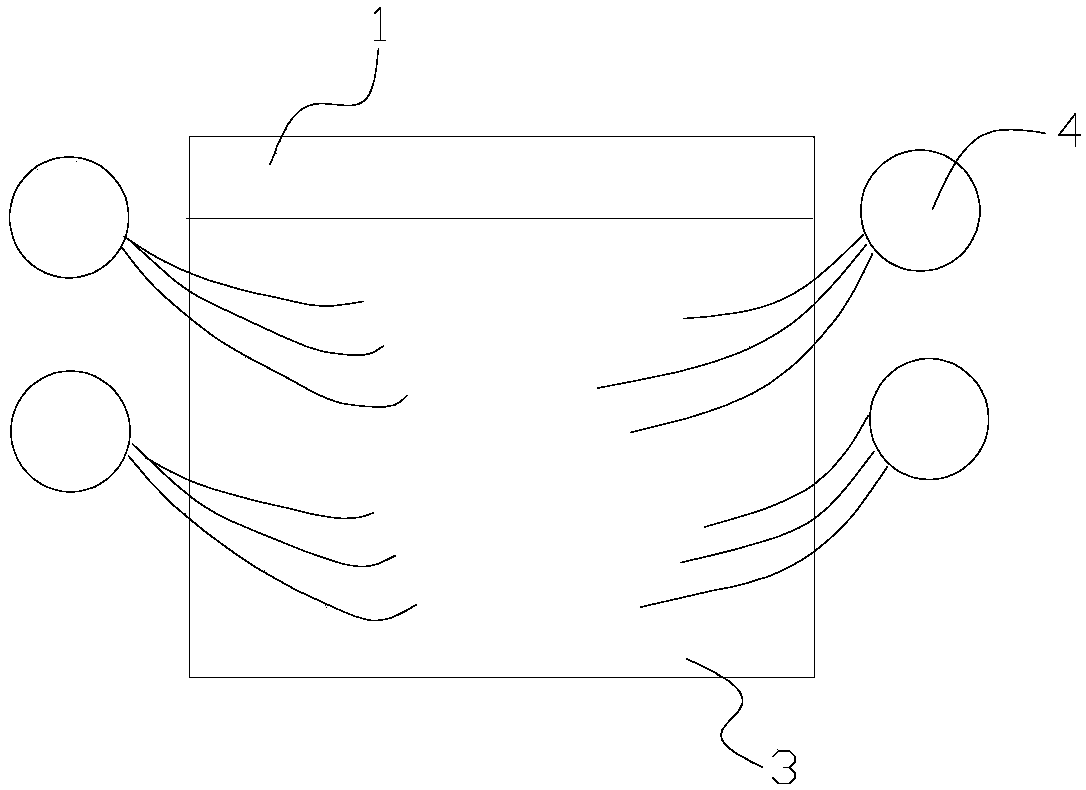

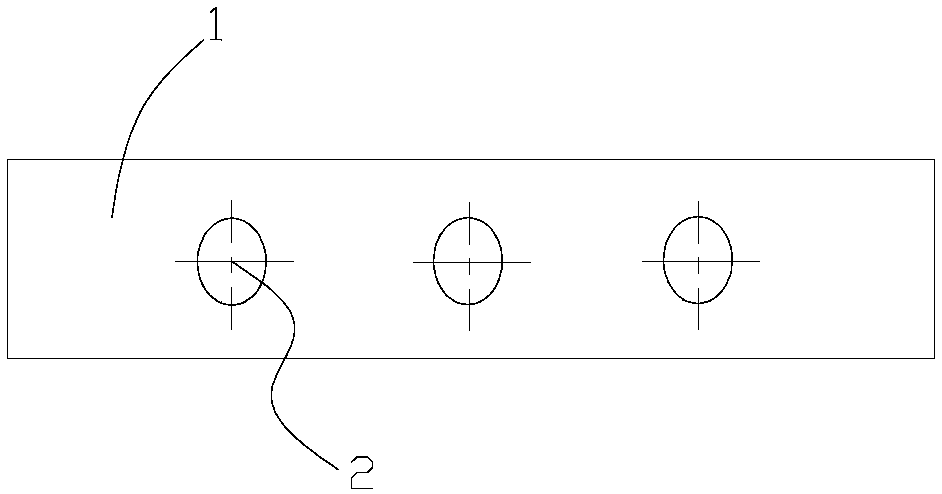

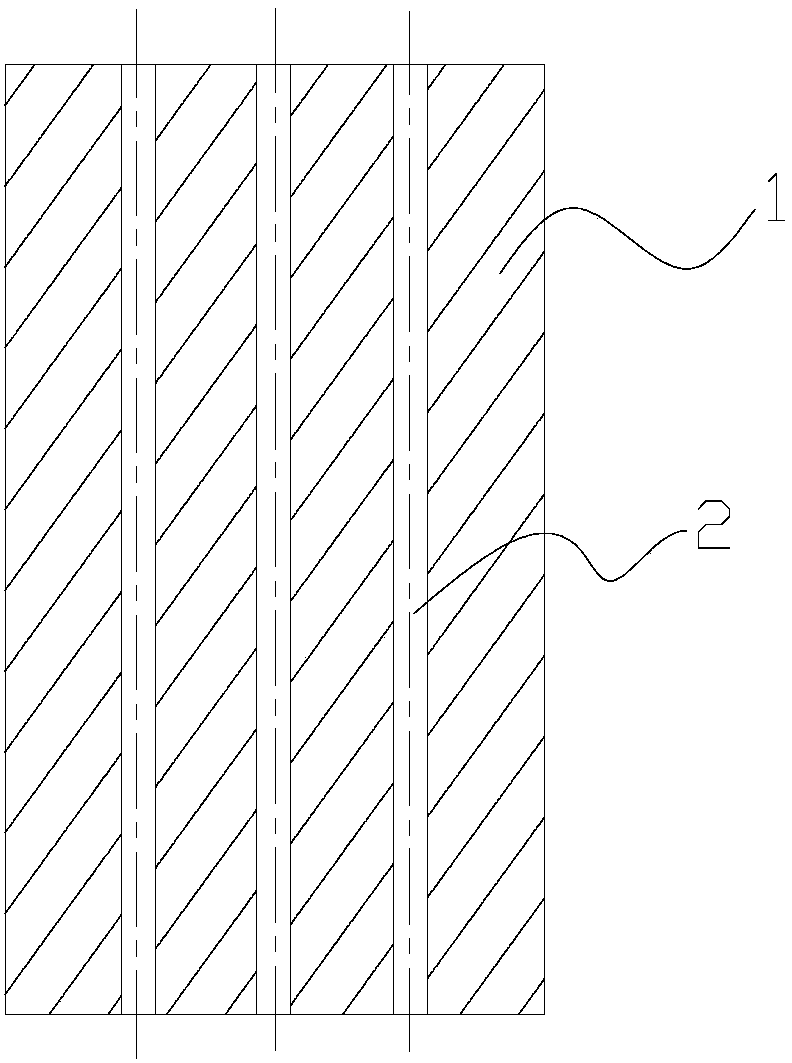

[0022] This embodiment is a high-efficiency, energy-saving and environment-friendly resin board for diamond wire cutting silicon wafers. The resin board is fixed on one side of the silicon ingot to be cut, and the filler of the resin board is glass fiber powder, and the filling ratio is 50%-60% of the weight of the resin. , when the resin board is processed, glass fiber powder is added after the resin is stirred. In this embodiment, the filler of the resin board is changed from the original aluminum hydroxide to glass fiber powder. In this embodiment, the size of the resin board is adjusted from the existing 156*700*15mm to 156*700*25mm, and the thickness is increased to 25mm. When the thickness of the resin board is controlled to be 25mm by adding glass fiber powder, the hardness is reduced from Shore A93 to Shao A50, density from 1.5g / cm 3 Reduced to 0.6g / cm 3 . Such as figure 2 and image 3 As shown, three circular through-holes 2 are arranged in the middle of the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com