Direct coal liquefaction cycle solvent, preparation method thereof and application thereof

A technology for direct coal liquefaction and solvent recycling, which is applied in the field of coal liquefaction to achieve the effects of improving diesel yield, alleviating deposition and coking, and promoting conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

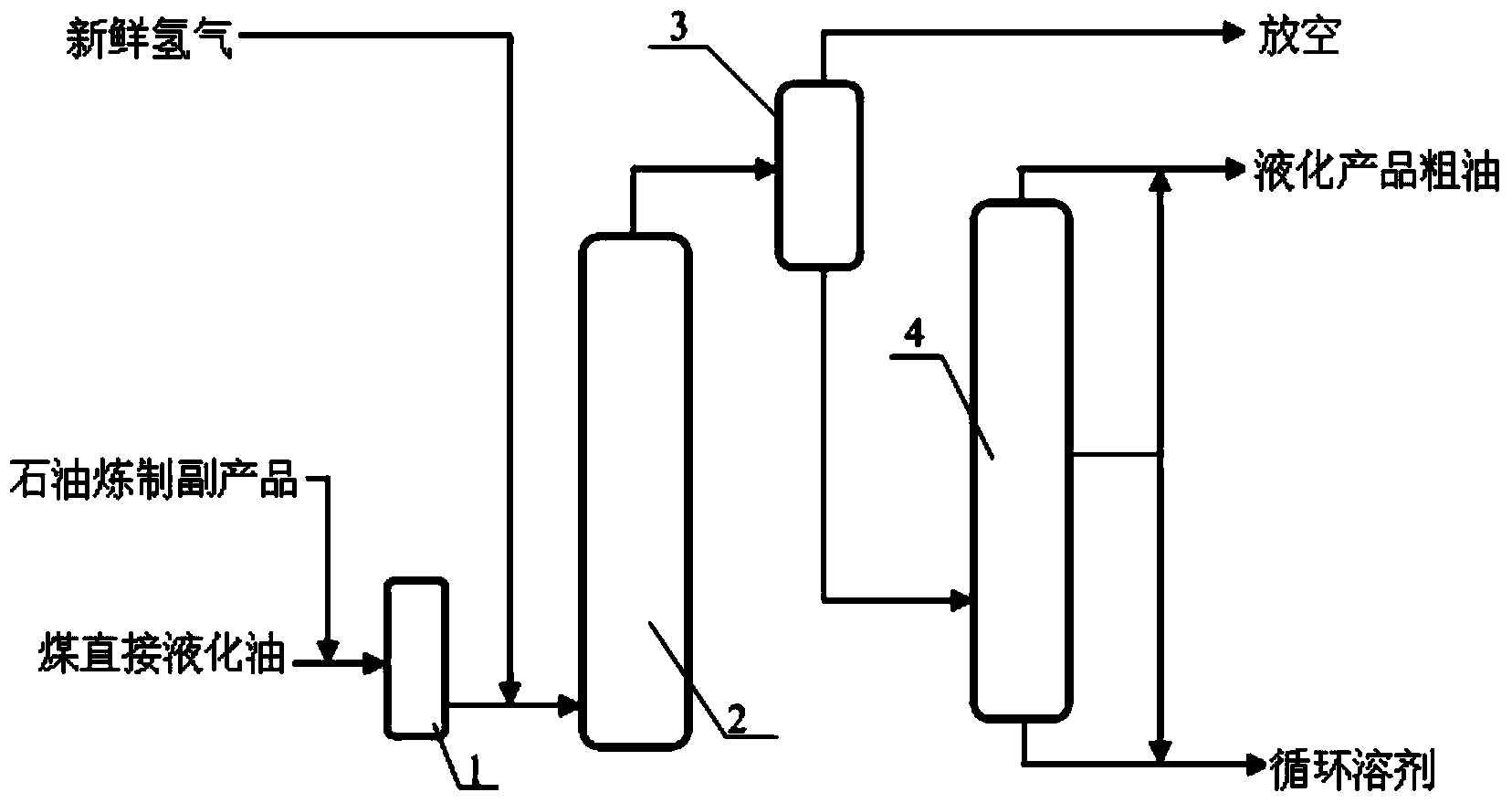

[0026] In a typical implementation of the present invention, a method for preparing a circulating solvent for direct coal liquefaction is provided. The preparation method includes: step S1, hydrogenating the mixture of petroleum refining by-products and direct coal liquefaction oil to obtain hydrogenated Hydrogen product; step S2, fractionating the hydrogenation product to obtain light distillate, middle distillate and heavy distillate; and step S3, mixing heavy distillate and part of middle distillate to obtain direct liquefaction of coal Circulate solvent.

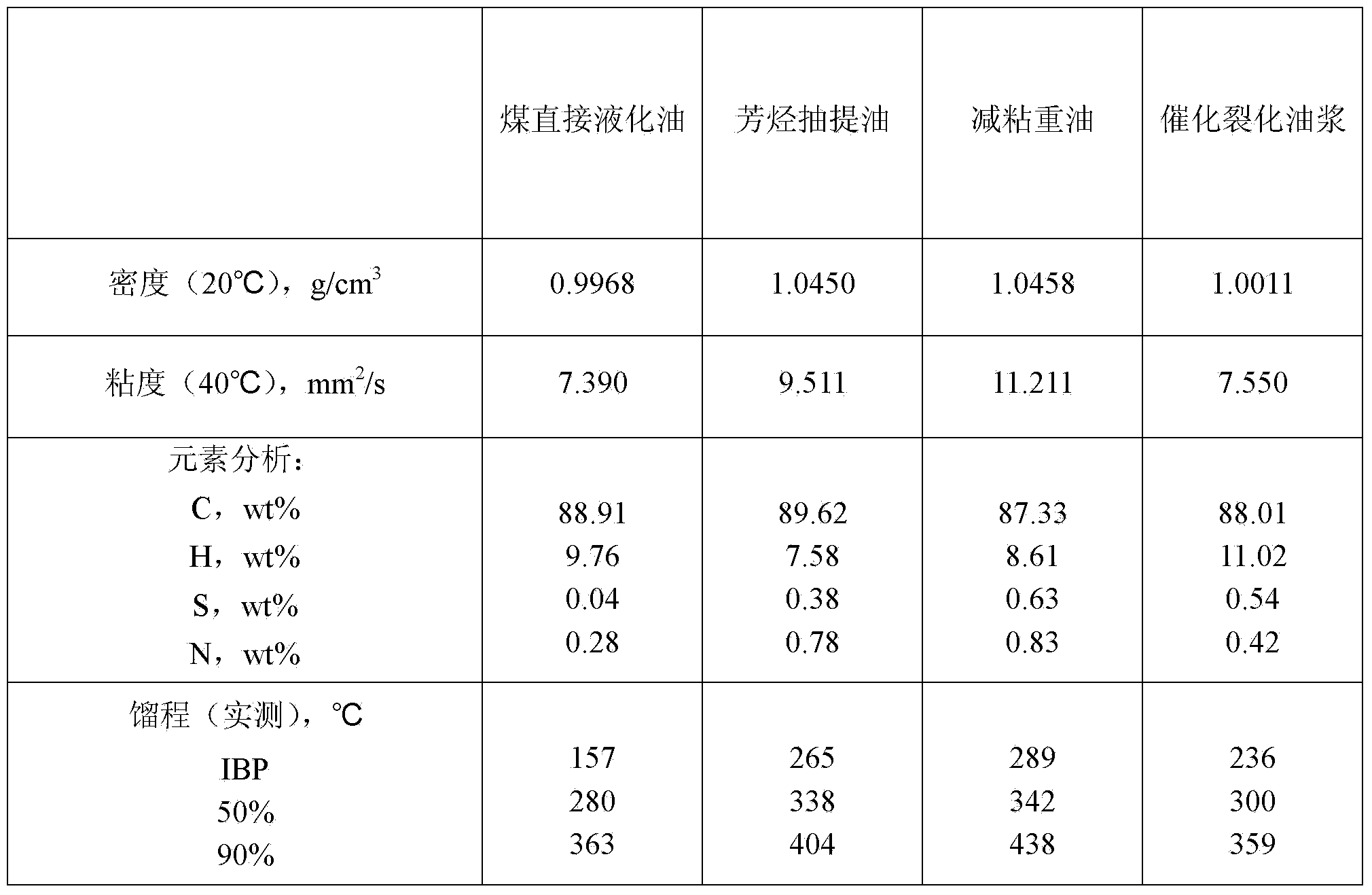

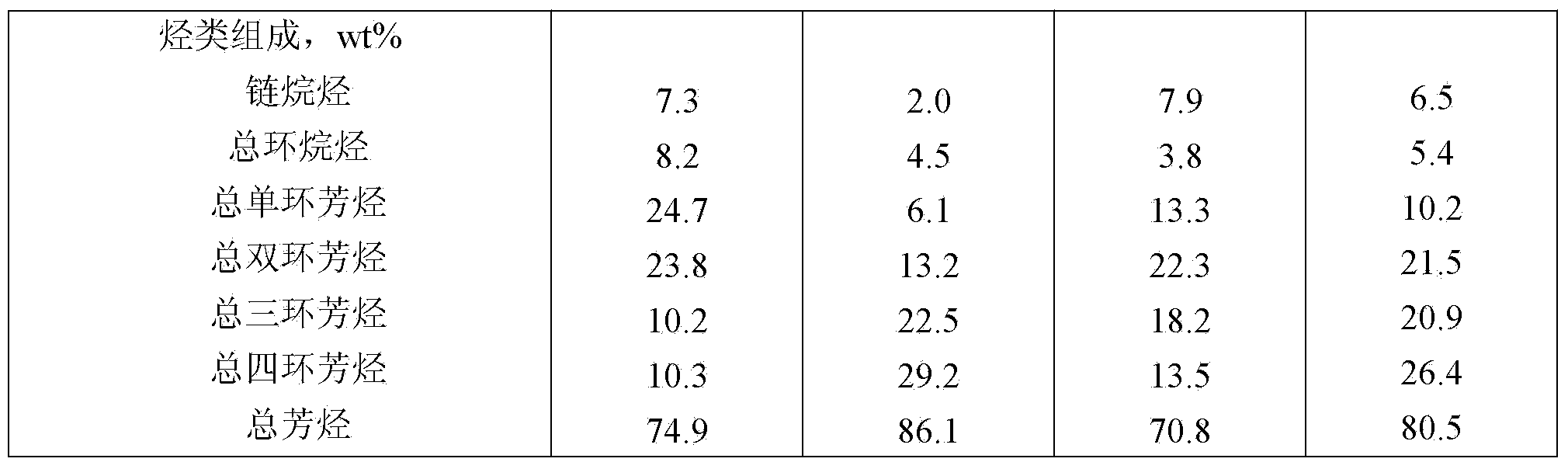

[0027] The present invention uses coal direct liquefied oil blended with petroleum refining by-products as the raw material for making direct coal liquefaction circulating solvents. On the one hand, because the petroleum refining by-products contain a large amount of aromatic hydrocarbons, the products after hydrogenation are rich in components such as tetrahydronaphthalene, thereby It can significantly improve the hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com