Technique for preparing white carbon black by phosphoric acid precipitation and directly coproducing sodium phosphate

A technology of sodium phosphate and white carbon black, applied in the field of sodium phosphate, can solve the problems of discount of application value and economic value, difficult process technology, and reduced product quality, etc., to solve the pressure of environmental protection, improve adaptability, Inclusion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

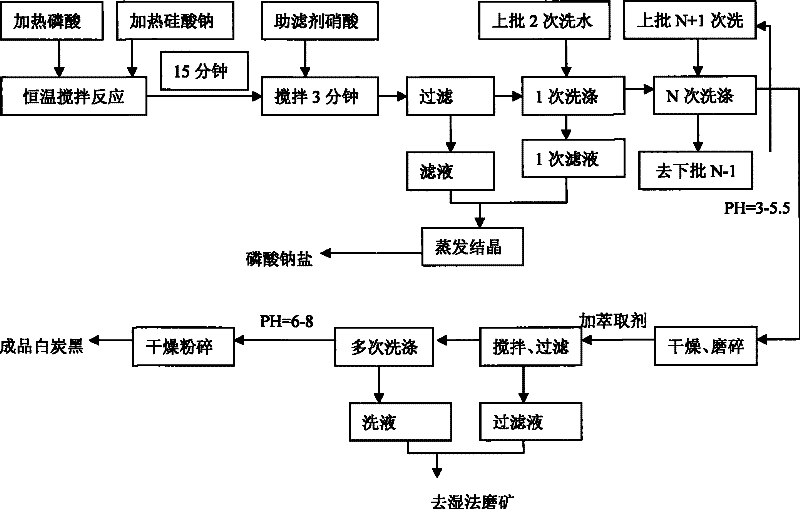

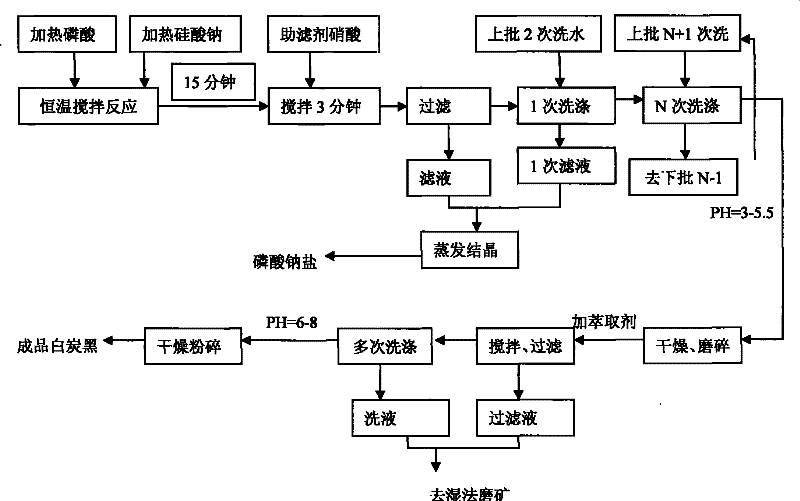

Method used

Image

Examples

Embodiment 1

[0028] Add sodium silicate with a weight of 1000g, a modulus of 3.1, and a content of 34.56% and a phosphoric acid solution with a content of 60% in two 1000ml containers to ensure that the molar ratio of sodium to phosphorus is 1.0. At 80°C, add at a constant speed at the same time, and react for 15 minutes in an 80°C constant temperature reaction vessel with rapid stirring. Add 25 ml of nitric acid with a volume ratio of 1:1, and continue stirring for 3 minutes. Vacuum filter while hot, wash once with water, recover the reaction filtrate and wash filtrate once, then wash with water until the pH is 3.5-5.5, and recover the filtrate for washing of the next batch of materials. Dry at 105°C for 2 hours, grind, add dilute nitric acid and stir thoroughly, filter with suction, wash with water, filter with suction until neutral, and recover the filtrate. The resulting filter cake is dried at 105°C and crushed to become a white carbon black product.

Embodiment 2

[0031] Add sodium silicate with a weight of 1000g, a modulus of 3.1, and a content of 34.56% and a phosphoric acid solution with a content of 60% in two 1000ml containers respectively to ensure that the molar ratio of sodium to phosphorus is 0.9, and keep the temperature in a water bath to At 90°C, add at a constant speed at the same time, and react for 15 minutes in a 90°C constant temperature reaction vessel with rapid stirring. Add 25 ml of nitric acid with a volume ratio of 1:1, and continue stirring for 3 minutes. Vacuum filter while hot, wash once with water, recover the reaction filtrate and wash filtrate once, then wash with water until the pH is 3.5-5.5, and recover the filtrate for washing of the next batch of materials. Dry at 105°C for 2 hours, grind, add dilute nitric acid and stir thoroughly, filter with suction, wash with water, filter with suction until neutral, and recover the filtrate. The resulting filter cake is dried at 105°C and crushed to become a white...

Embodiment 3

[0033] Add sodium silicate with a weight of 1500g, a modulus of 3.1, and a content of 34.56% and a phosphoric acid solution with a content of 60% in two 1000ml containers to ensure that the molar ratio of sodium to phosphorus is 0.95. At 90°C, add at a constant speed at the same time, and react for 15 minutes in a 90°C constant temperature reaction vessel with rapid stirring. Add 25 ml of nitric acid with a volume ratio of 1:1, and continue stirring for 3 minutes. Vacuum filter while hot, wash once with water, recover the reaction filtrate and wash filtrate once, then wash with water until the pH is 3.5-5.5, and recover the filtrate for washing of the next batch of materials. Dry at 105°C for 2 hours, grind, add dilute nitric acid and stir thoroughly, filter with suction, wash with water, filter with suction until neutral, and recover the filtrate. The resulting filter cake is dried at 105°C and crushed to become a white carbon black product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com