Hydrogenation combined process

A combined process and hydrogen technology, applied in the fields of hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc., can solve problems that have not been reported yet, and achieve the effects of saving device investment, reducing wear and reducing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

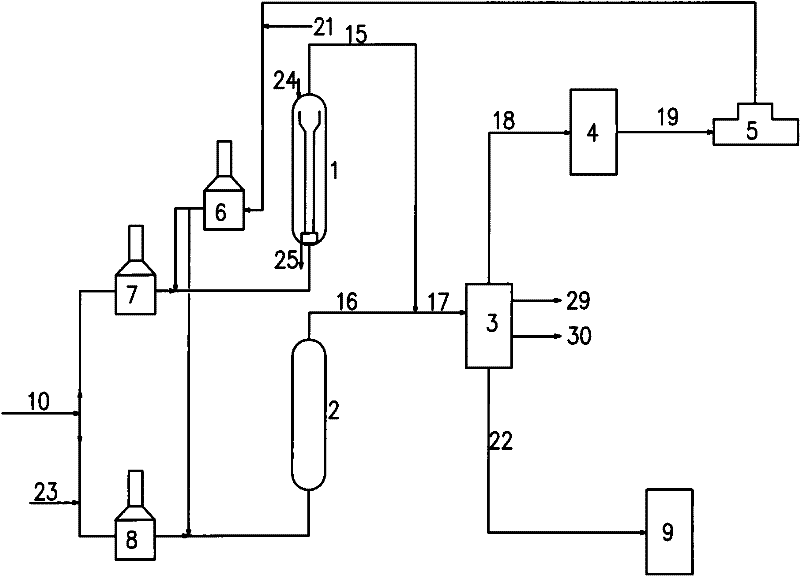

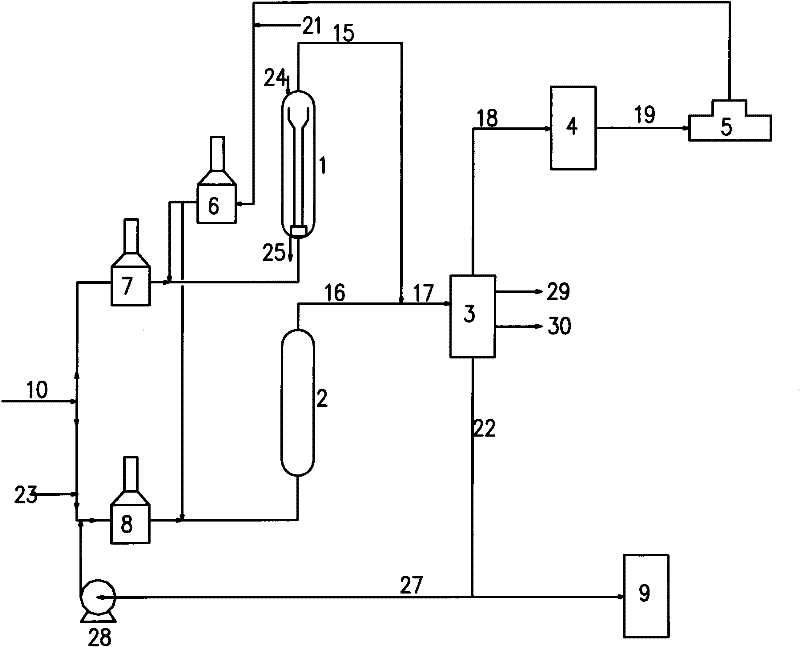

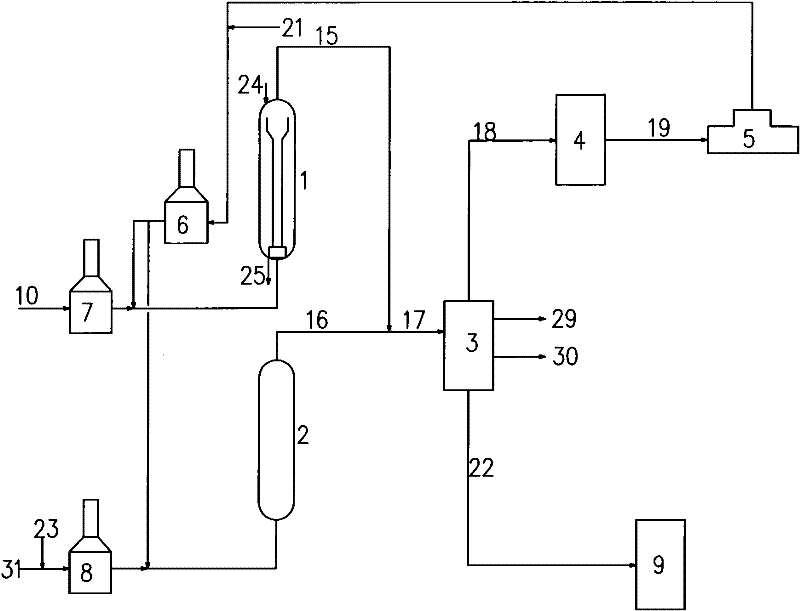

[0031] Such as figure 1 As shown, when the heavy metal content of the heavy and residual oil in the refinery is less than 800 μg / g, the raw oil 10 is divided into two parts: one part is heated by the raw oil heating furnace 7, mixed with hydrogen heated by the hydrogen heating furnace 6, and then enters The ebullating bed reactor 1 is equipped with a catalyst adding system 24 and a catalyst discharging system 25 inside the ebullating bed reactor 1. After the other part is mixed with the suspension bed catalyst 23, it is heated by the raw material oil heating furnace 8 and then heated by the hydrogen heating furnace 6. The final hydrogen is mixed and then enters the suspended bed reactor 2.

[0032] The pressure of the ebullated bed reactor 1 is 8-20 MPa (gauge pressure), the temperature is 350-550° C., and the hydrogen-oil volume ratio is 500-1500. The pressure of the suspended bed reactor 2 is 8-20MPa (gauge pressure), the temperature is 350-550°C, and the volume ratio of hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com