Sludge or organic garbage high-low temperature coupling themolysis method

An organic waste, high and low temperature technology, which is applied in the directions of organic fertilizer, pyrolysis treatment sludge, sewage/sludge fertilizer, etc. problems, to achieve the effect of saving equipment investment, saving energy, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

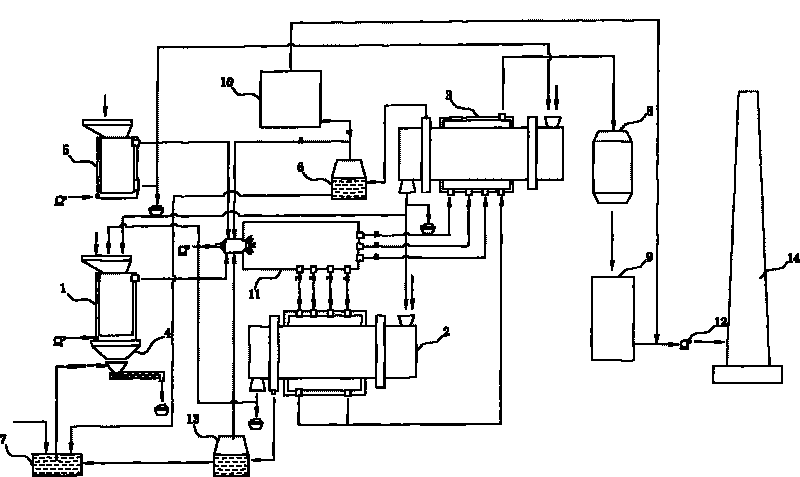

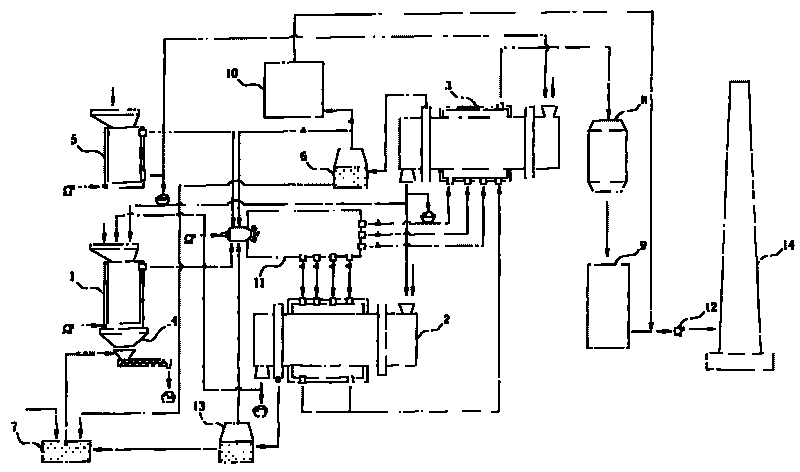

Image

Examples

example 1

[0035] The daily output of a municipal sludge plant in a southern city is 300t / d, the calorific value on a dry basis is 18200KJ / kg, the initial water content is 80%, the ash content on a dry basis is 45%, and the carbon content on a dry basis is 36%. Harmful substances and heavy metals The content meets the requirements of urban sewage treatment plant sludge disposal-agricultural mud (CJ / T309-2009), and mineral oil and benzo(α)pyrene were not detected. There are abundant straws waiting to be processed locally, and the most commonly used fertilizers in the area are potassium and nitrogen fertilizers.

[0036] In the first step, the wet sludge with a moisture content of 80% is first sent to the low-temperature drying and cracking furnace 3 for cracking to obtain partially carbonized biological fertilizer. stay for 6 minutes; the gas produced by cracking is sent to the first condenser 6 for condensation, the condensed tar is sent to the regulating liquid storage tank 7, and the u...

example 2

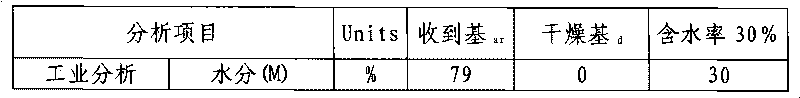

[0041] The daily output of municipal sludge in a northwestern city is 250t / d, and the analysis data is as follows:

[0042]

[0043]

[0044] The data in the above table shows that the content of heavy metal Cu does not meet the requirements of grade A sludge of urban sewage treatment plant sludge disposal - agricultural mud (CJ / T309-2009), but meets the requirements of grade B sludge. In addition, mineral oil and benzo (α)pyrene was not detected.

[0045]In the first step, the sludge with a moisture content of 79% is sent to the low-temperature drying and cracking furnace 3 for drying and cracking to obtain partially carbonized biological fertilizers. The drying and cracking temperature is 150°C and the time is about 90 minutes; The first condenser 6 condenses, and the condensed tar is sent to the regulating liquid storage tank 7, and the uncondensed gas is sent to the deodorization device 10 and sent to the chimney 14 for discharge through the induced draft fan 12; the...

example 3

[0048] The daily output of municipal sludge in a northwestern city is 200t / d, and the properties of the sludge are the same as in Example 2. At the same time, local residents collect cattle, sheep and horse manure to pile up randomly, and fertilize or use it as fuel after drying.

[0049] When using the method of the present invention to process, in the first step, the sludge with a moisture content of 79% and the newly collected cattle, sheep and horse manure with a moisture content below 80% are sent to the low-temperature drying and cracking furnace 3 for drying and cracking to obtain partially charred manure. For biological fertilizers, the drying and cracking temperature is 150°C, and the time is about 90 minutes; the gas generated by cracking is sent to the first condenser 6 for condensation, the condensed tar is sent to the regulating liquid storage tank 7, and the uncondensed gas is sent to the deodorization device 10 Sent to the chimney 14 for discharge through the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com