Composition for removing catalyst powder from catalytic cracking slurry and removal method

A composition and catalyst technology, which can be used in tar processing, hydrocarbon oil dehydration/demulsification, petroleum industry, etc., can solve the problems affecting the oil slurry processing capacity and processing cost, and achieve the reduction of input cost, improvement of removal rate, The effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

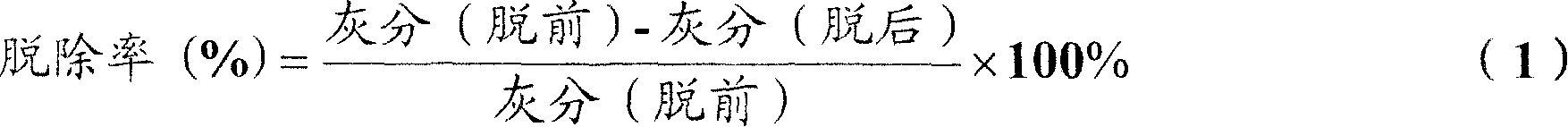

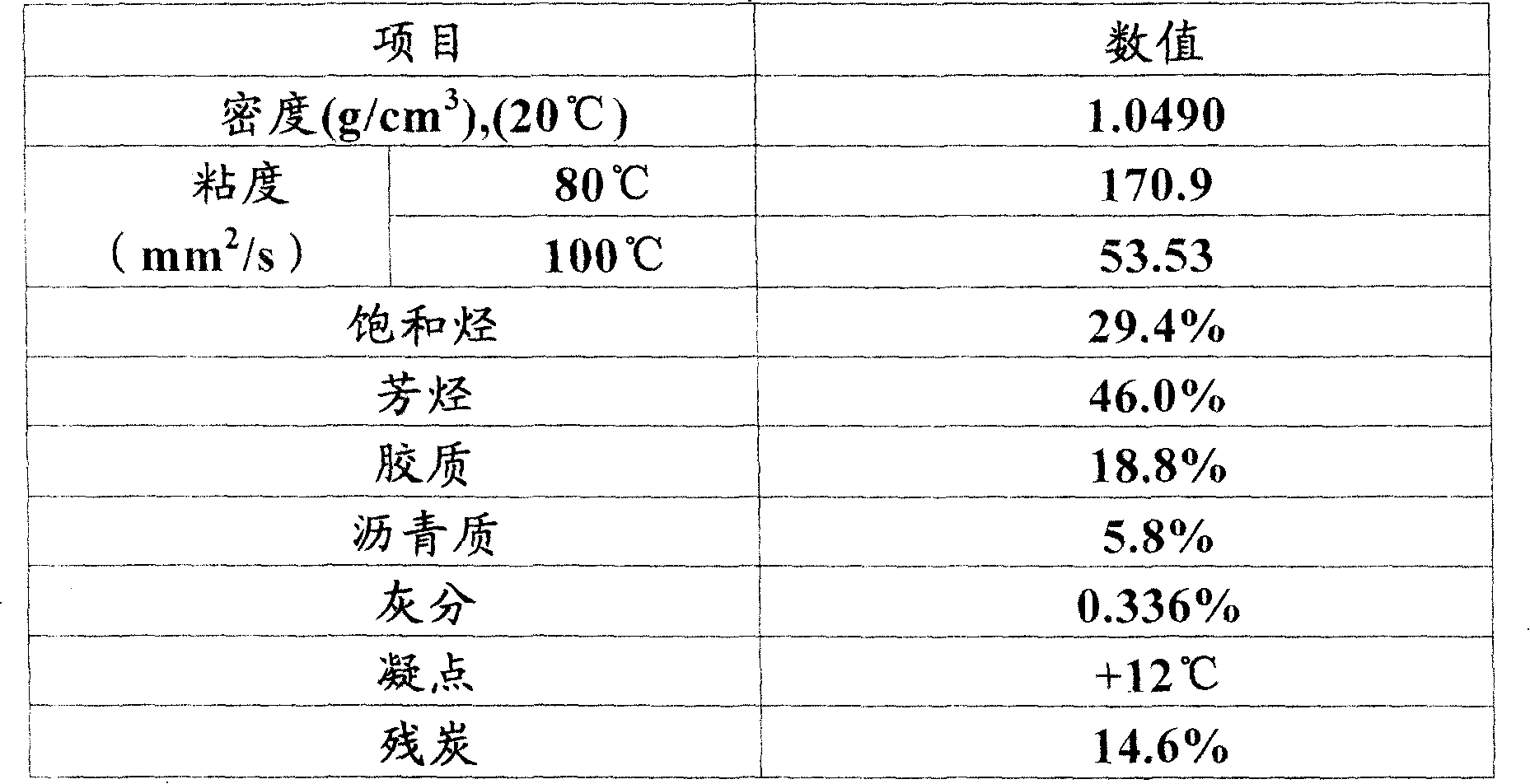

[0038] The properties of the FCC oil slurry processed in this embodiment are shown in Table 1.

[0039] Table 1 Properties of FCC oil slurry

[0040]

[0041]6.4 g of glucose was added to 15.2 g of water, 0.8 g of 2% demulsifier BP2040 was added, and mixed with 1.6 g of 0.5% wetting agent (see Table 2 for details) to form a solution. After the solution is preheated to 95°C, mix it with 160g of FCC oil slurry preheated to 100°C, click and mix 50 times with a juicer, pour it into a test tube, apply an electric field in the demulsifier, and let it stand still to break the emulsion and separate the water , The electric field strength is 200v / cm. Take it out after 1 hour, pump out the lower layer of water, then take the treated FCC oil slurry and stir it evenly to measure the ash content, the results are shown in Table 2.

[0042] Table 2 Treatment effect of different wetting agents

[0043] D

[0044]

[0045] It can be seen from the above table that the...

Embodiment 2

[0047] The properties of the processed FCC oil slurry are the same as in Example 1.

[0048] Heat 160g FCC oil slurry to 100°C, keep the temperature and slowly add 15.2g water, 6.4g glucose, 0.8g 2% demulsifier BP2040 and 1.6g 0.5% wetting agent dodecylbenzenesulfonic acid under stirring condition sodium. After mixing thoroughly to dissolve it fully, use a juicer to click and mix 50 times, pour it into a test tube, apply an electric field in the demulsifier, let it stand for demulsification and water separation, the electric field strength is 200v / cm, take it out after 1 hour, and pump out the lower layer of water , and then take the treated FCC oil slurry and stir it evenly to measure the ash. The results show that: compared with the method prepared in advance, this method can also remove the catalyst powder in the FCC oil slurry, and the removal rate reaches 78.3%, and the ash content in the FCC oil slurry is reduced to 0.072%.

Embodiment 3

[0050] The properties of the processed FCC oil slurry are the same as in Example 1.

[0051] Take 6.4g glucose and add 47.2g water, add 0.8g 2% demulsifier BP2040, and mix with 0.5% wetting agent sodium dodecylbenzenesulfonate to form a solution. After the solution is preheated to 95°C, mix it with 160g of FCC oil slurry preheated to 100°C, click and mix 50 times with a juicer, pour it into a test tube, apply an electric field in the demulsifier, and let it stand still to break the emulsion and separate the water . The electric field strength is 200v / cm, take it out after 1 hour, pump out the lower layer of water, then take the treated FCC oil slurry and stir it evenly to measure the ash content, the results are shown in Table 3.

[0052] Table 3 Treatment effect of wetting agent with different dosage

[0053] Dosage of wetting agent

[0054] It can be seen from the above table that the catalyst powder can be removed from the FCC oil slurry and the ash content can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com