Method for deep processing coal tar

A coal tar and hydrogenation device technology, applied in tar processing, petroleum industry, etc., can solve the problems of low efficiency, failure to realize the hydrogenation of the whole fraction of coal tar, and the inability to deeply process coal tar, etc., to extend the operation cycle, The effect of expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

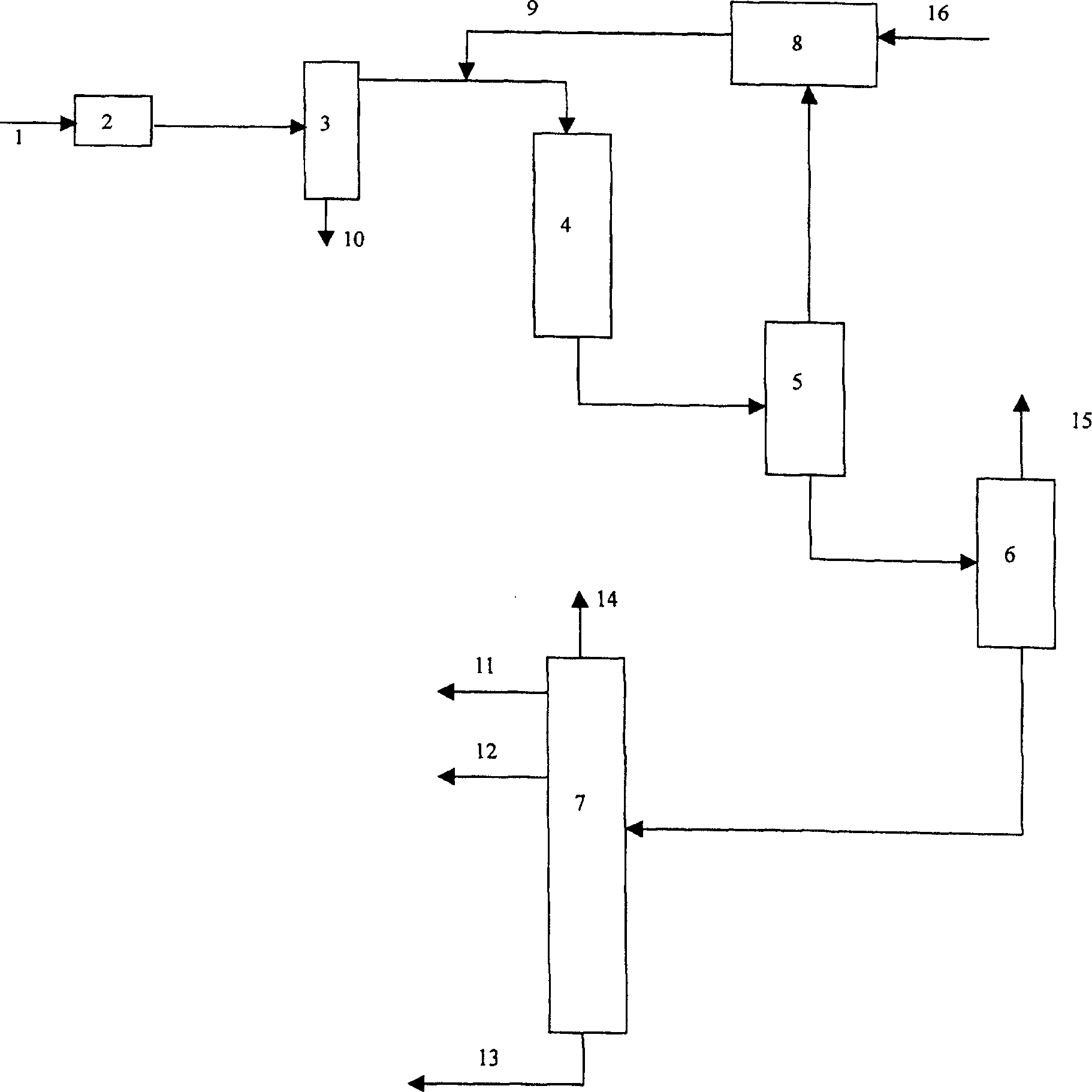

Image

Examples

Embodiment 1~6

[0062] In Examples 1-6, the same coal tar raw material was used to treat coal tar under different operating conditions, and the properties of the raw materials used are shown in Table 1.

[0063] coal tar

Elemental analysis (mol%)

C

83.10

H

6.75

O

9.09

S

0.177

N

0.8754

Metal elements (μg / g)

Ca

31.33

Ni

1.16

V

0.09

Fe

34.70

Toluene insoluble matter, %

0.55

Asphaltenes, %

17.1

Charcoal residue, %

8.40

Precipitate,%

0.14

Density at 20°C, g / cm 3

1.0615

Distillation range:

%

water

3.77

<180℃

3.54

180~240℃

9.89

240~300℃

11.95

300~360℃

13.87

360~380℃

3.45

[0064] The specific operation process is as follows:

[0065] The coal tar raw material 1 enters the...

Embodiment 7~10

[0069] In Examples 7-10, different coal tar raw materials were used to treat coal tar under the same operating conditions, and the properties of the raw materials used are shown in Table 3.

[0070] Example

[0071] The specific operation process is as described in Example 1, and the reaction conditions are shown in Table 4. Reactor catalysts include main catalysts and protective agents. The protective agent is filled in the upper part of the hydrogenation unit, and the content of molybdenum oxide in the protective agent is 7.0%, and the content of nickel oxide is 1.5%. The pore volume of described protecting agent is 0.55ml / g, and specific surface is 180m 2 / g. The loading amount of the protective agent is 10%, based on the total loading amount of the main catalyst and the protective agent. The main catalyst is packed in the lower part of the hydrogenation unit. In the main catalyst, the content of tungsten oxide is 21%, the content of molybdenum oxide is 8%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com