Graphene lithium-based lubricating grease used under high extreme pressure condition and preparation method thereof

A technology of lithium-based lubricating grease and graphene, which is applied in the field of lubricating oil, can solve problems such as many steps, high energy consumption, and complex process of modified hydroxylated graphene, and achieve uniform performance, low energy consumption, and excellent high drop point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 is used for the raw material and the preparation of the graphene lithium base lubricating grease of high extreme pressure condition

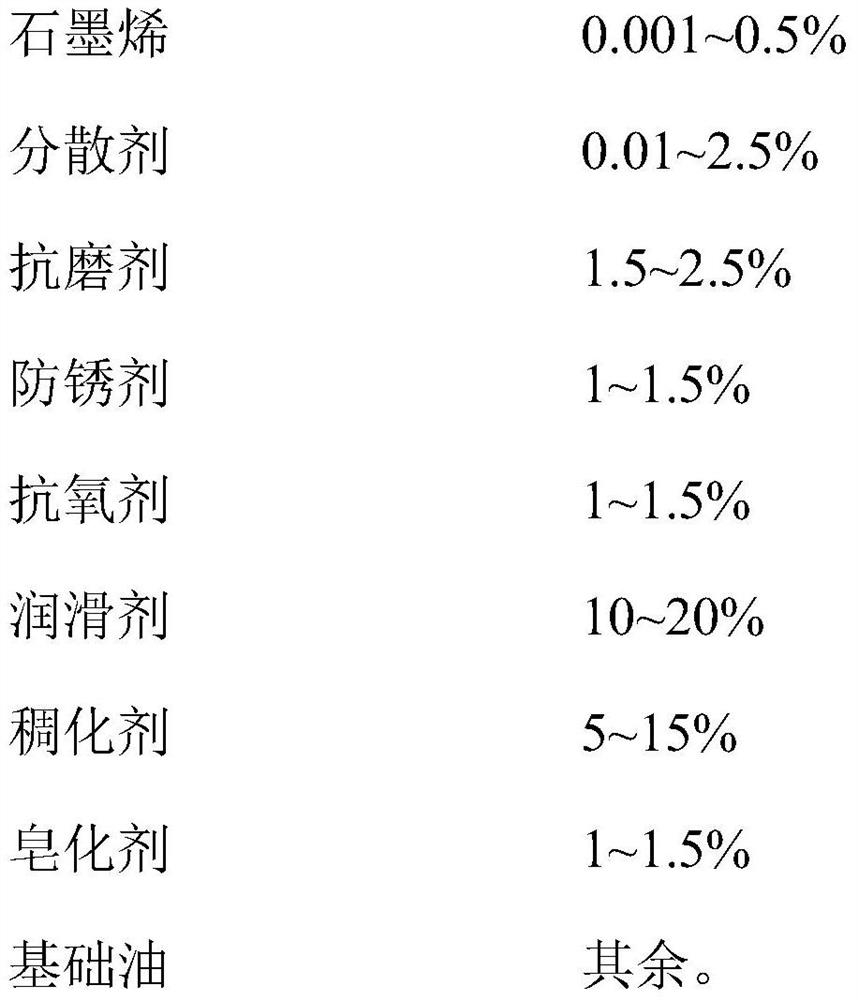

[0043] Prepare raw materials by the following mass percentages:

[0044]

[0045] The three-dimensional structure graphene is a powder material with a honeycomb-like structure composed of two-dimensional graphene sheets, with a surface area of 1200m 2 / g, the percentage of heteroatoms is 15%, and the basic characteristics of its structure meet the requirements of technical standards DB 45 / T 1421-2016 and DB 45 / T 1425-2016. The preparation method of graphene lithium base lubricating grease is as follows:

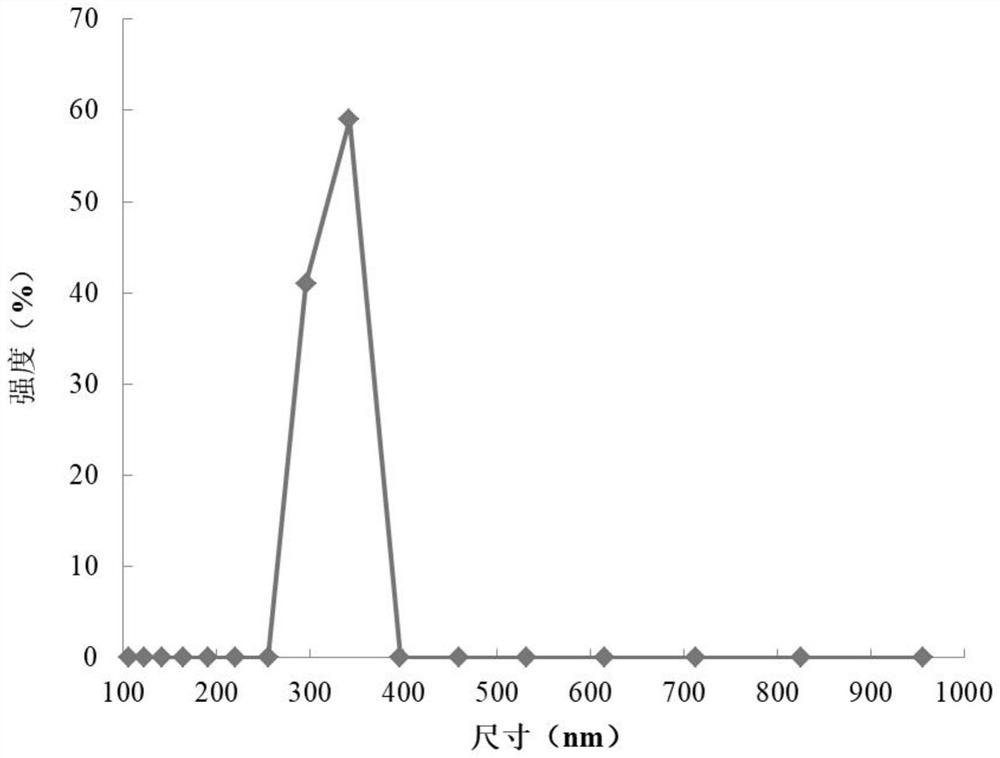

[0046] (1) Stir and mix graphene, dispersant and a part of base oil evenly, make graphene account for 0.1% of the total mass of the mixed solution, use sand mill speed 2000r / min to grind for 0.1h to prepare graphene dispersion;

[0047] (2) Mix part of the base oil with the thickener, and heat up to 80°C to obtain the ...

Embodiment 2

[0052] Embodiment 2 is used for the raw material and the preparation of the graphene lithium base lubricating grease of high extreme pressure condition

[0053] Prepare raw materials by the following mass percentages:

[0054]

[0055] The above-mentioned three-dimensional graphene is a powder material with a honeycomb-like structure composed of two-dimensional graphene sheets, with a surface area of 1400m 2 / g, the percentage of heteroatoms is 10%, and the basic characteristics of its structure meet the requirements of technical standards DB 45 / T 1421-2016 and DB 45 / T 1425-2016. The preparation method of graphene lithium base lubricating grease is as follows:

[0056] (1) Graphene, dispersant and a part of base oil are stirred and mixed uniformly, so that Graphene accounts for 3% of the total mass of the mixed solution, and the Graphene dispersion is obtained by using a sand mill speed of 2000r / min for sand grinding for 5h;

[0057] (2) Mix part of the base oil with th...

Embodiment 3

[0062] Embodiment 3 is used for the raw material and the preparation of the graphene lithium base lubricating grease of high extreme pressure condition

[0063] Prepare raw materials by the following mass percentages:

[0064]

[0065] The above-mentioned three-dimensional graphene is a powder material with a honeycomb-like structure composed of two-dimensional graphene sheets, with a surface area of 1500m 2 / g, the percentage of heteroatoms is 12%, and the basic characteristics of its structure meet the requirements of technical standards DB 45 / T 1421-2016 and DB 45 / T 1425-2016. The preparation method of graphene lithium base lubricating grease is as follows:

[0066] (1) Stir and mix graphene, dispersant and a part of base oil evenly, make graphene account for 7% of the total mass of the mixed solution, use sand mill speed 2000r / min sand mill 8h to make graphene dispersion;

[0067] (2) Mix part of the base oil with the thickener, and heat up to 110°C to obtain the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com