Auxiliary agent-modified catalyst for CO-CO2 co-hydrogenation synthesis of methanol

A technology of CO2 and catalysts, which is applied in the field of additive modified catalysts, can solve the problems of complex preparation methods, lower methanol selectivity, and low overall yield, and achieve the effects of simple preparation process, high selectivity, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

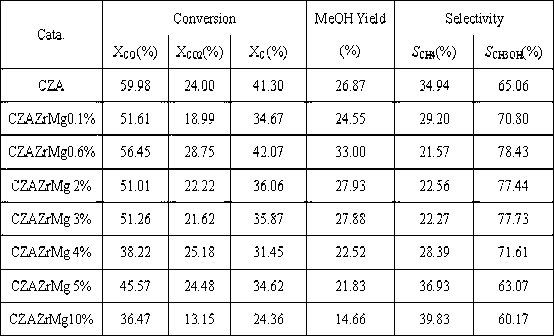

[0017] Example 1: CO and CO 2 The components and the ratio of each component of the co-hydrogenation synthesis methanol catalyst are Cu:Zn:Al molar ratio is 6.0:3.2:0.8, Zr and Mg are not included.

[0018] During preparation, 18.63 grams of Cu (NO 3 ) 2 ·3H 2 O, 12.23 g Zn(NO 3 ) 2 ·6H 2 O and 3.85 g Al(NO 3 ) 3 9H 2 O was dissolved in deionized water and mixed with 1.1mol / L Na 2 CO 3 The solution is co-currently titrated into 100ml of deionized water stirred at a high speed, while keeping the pH of the solution at 7-8, and the reaction temperature at 70°C. Stir the reaction for 1 hour, then leave it to age at room temperature for 2 hours, suction filter, wash, and dry the solid precipitate at 110°C for 12 hours to obtain a catalyst precursor, which is then placed in a muffle furnace and calcined at 500°C for 5 hours. After cooling, grind, tablet, and sieve to obtain a catalyst in the range of 20-40 mesh.

Embodiment 2

[0019] Example 2: CO and CO modified by this additive 2 The components and the ratio of each component of the co-hydrogenation methanol synthesis catalyst are: (CuZnAl): (ZrMg) mass percentage is 99.4%: 0.6%, where Cu: Zn: Al molar ratio is 6.0: 3.2: 0.8, Zr: Mg molar The ratio is 2:1.

[0020] During preparation, 18.52 grams of Cu(NO 3 ) 2 ·3H 2 O, 12.16 g Zn(NO 3 ) 2 ·6H 2 O, 3.82 g Al(NO 3 ) 3 9H 2 O and 0.1420 g Zr(NO 3 ) 4 Dissolve in deionized water, mix it with 1.1mol / L Na 2 CO 3The solution was titrated concurrently into 100ml of deionized water stirred at high speed, while keeping the pH of the solution at 7-8, and the reaction temperature at 70°C. After the nitrate solution was added dropwise, the pH was adjusted to 9, and continued stirring at the reaction temperature React for 1 hour, then stand and age at room temperature for 2 hours, filter with suction, wash the solid precipitate with deionized water, and dry at 110°C for 12 hours to obtain a cataly...

Embodiment 3

[0021] Example 3: CO and CO modified by this additive 2 The components and the ratio of each component of the co-hydrogenation methanol synthesis catalyst are: (CuZnAl): (ZrMg) mass percentage is 98%: 2%, where Cu: Zn: Al molar ratio is 6.0: 3.2: 0.8, Zr: Mg molar The ratio is 2:1.

[0022] During preparation, according to the mass percentage of CuZnAl and ZrMg is 98.0%: 2.0%, weigh 18.25 grams of Cu (NO 3 ) 2 ·3H 2 O, 11.99 g Zn(NO 3 ) 2 ·6H 2 O, 3.77 g Al(NO 3 ) 3 9H 2 O , 0.47 g Zr(NO 3 ) 4 Dissolve in deionized water, mix it with 1.1mol / L Na 2 CO 3 The solution was titrated concurrently into 100ml of deionized water stirred at high speed, while keeping the pH of the solution at 7-8, and the reaction temperature at 70°C. After the nitrate solution was added dropwise, the pH was adjusted to 9 and kept at the reaction temperature to continue Stir the reaction for 1 hour, then leave it to age at room temperature for 2 hours, filter it with suction, wash the solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com