Integrative processing plant for high concentration organic wasted water

A high-concentration technology for organic wastewater treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, settling tanks, etc., can solve the problems of high consumption of pumps and water pipes, complicated system structure, and increased system cost , to reduce floor space, simplify system structure, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

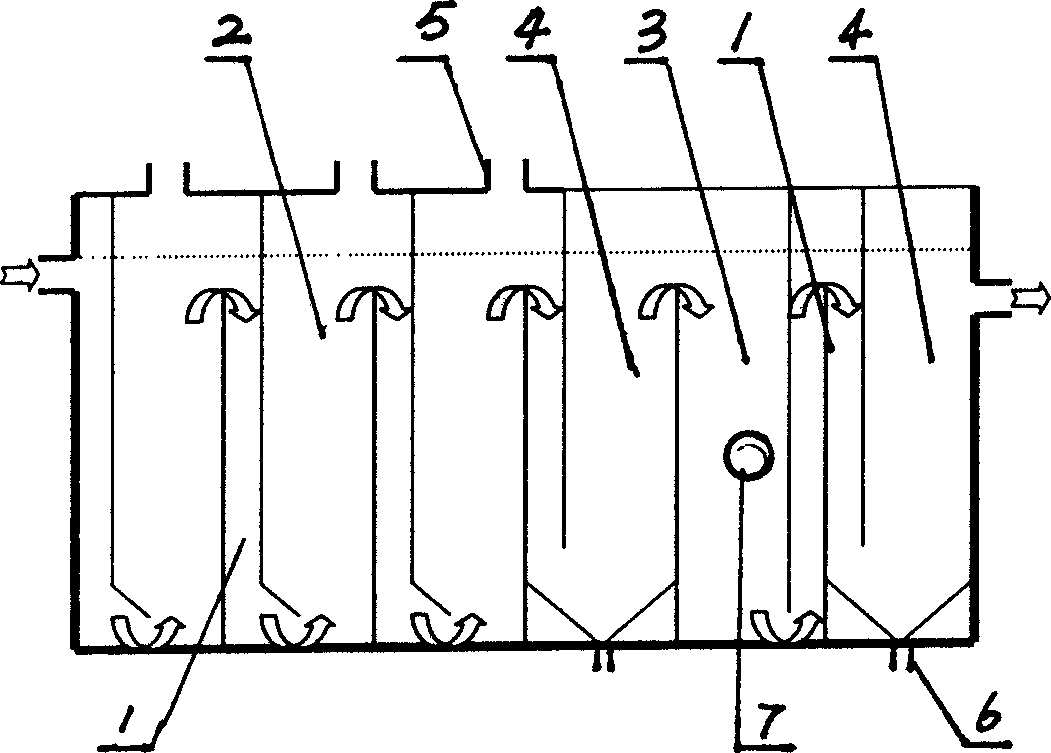

[0026] Embodiment 1: refer to figure 1 , an integrated high-concentration organic wastewater treatment device is a cuboid reaction pool with a length, width, and height of 72cm, 20cm, and 36cm, respectively, and is divided into three anaerobic reaction chambers 2 and one downstream by a vertical baffle 1. An aerobic reaction chamber 3 and two precipitation chambers 4 are composed, and each of the above reaction chambers is an anaerobic reaction chamber, a precipitation chamber, an aerobic reaction chamber, and a precipitation chamber in series along the water flow direction. Wherein the anaerobic reaction chamber 2 is capped and is provided with an exhaust port 5 at its top; the sedimentation tank 4 and the aerobic reaction chamber 3 are all open, and the bottom of the sedimentation chamber 4 is provided with a sewage outlet 6, and the aerobic reaction chamber 3 The side wall is provided with inflation port 7. The use of a downflow aerobic reaction chamber can make the water ...

Embodiment 2

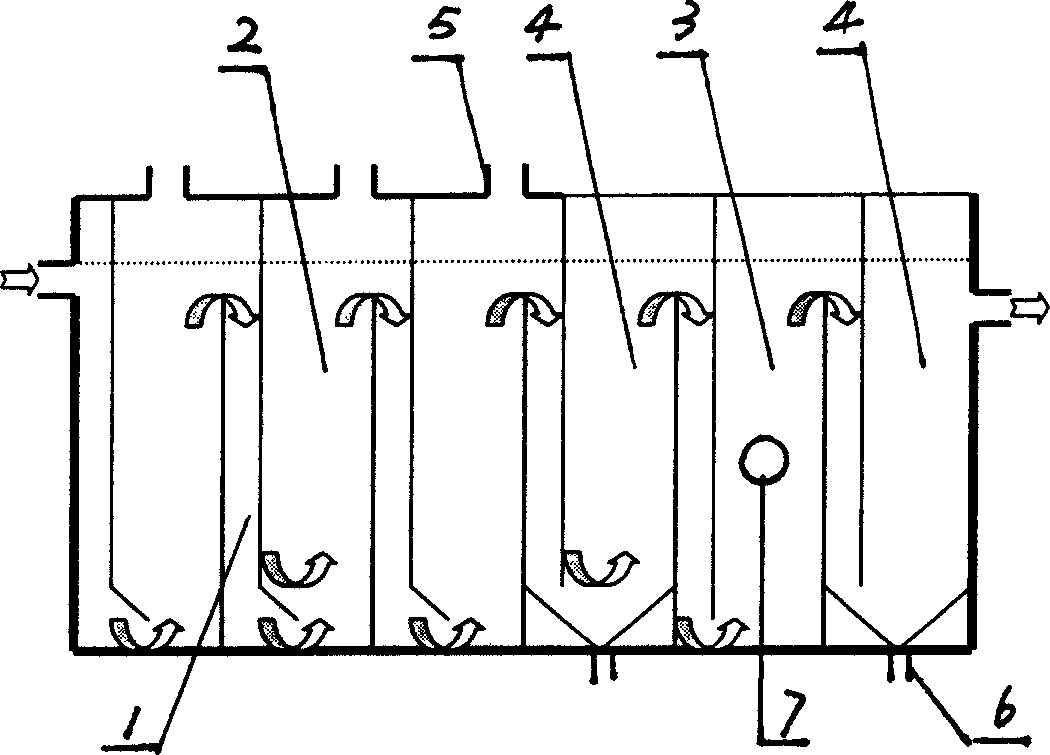

[0027] Embodiment 2: refer to figure 2 , an integrated high-concentration organic wastewater treatment device is a cuboid reaction pool with length, width, and height of 72cm, 20cm, and 36cm, respectively, and is divided into three anaerobic reaction chambers 2 and one upstream An aerobic reaction chamber 3 and two precipitation chambers 4 are composed, and each of the above reaction chambers is an anaerobic reaction chamber, a precipitation chamber, an aerobic reaction chamber, and a precipitation chamber in series along the water flow direction. Wherein the anaerobic reaction chamber 2 is capped and is provided with an exhaust port 5 at its top; the sedimentation tank 4 and the aerobic reaction chamber 3 are all open, and the bottom of the sedimentation chamber 4 is provided with a sewage outlet 6, and the aerobic reaction chamber 3 The side wall is provided with inflation port 7. The upflow aerobic reaction chamber overcomes the shortcomings of the downflow aerobic reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com