Overhead conveyor system for conveying packaging trays

A technology of conveyors and pallets, applied in the direction of transportation and packaging, packaging, conveyors, etc., to achieve the effect of small footprint and low possibility of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

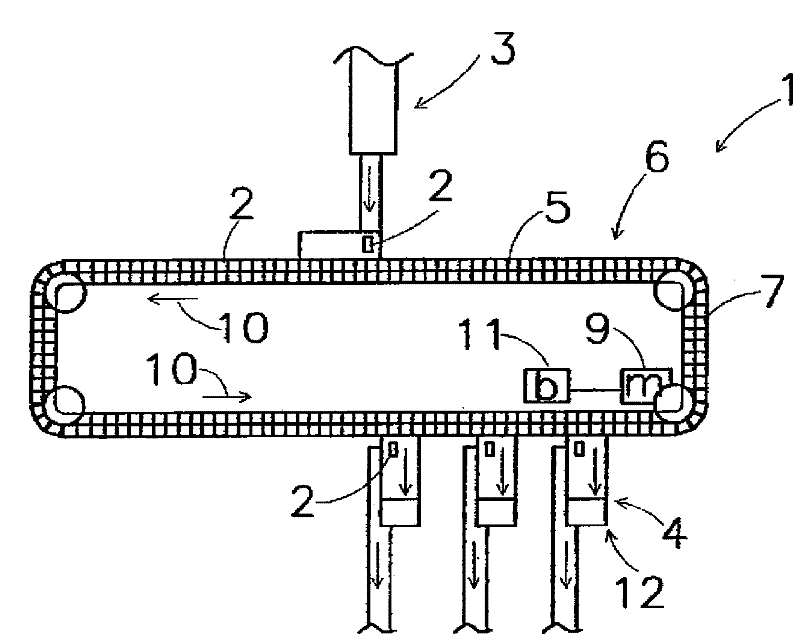

[0094] figure 1 is a schematic top view of a conveyor system 1 according to the invention. The conveyor system is provided with a guide rail 5 , a plurality of trolleys and a plurality of tray carriers 7 along an endless conveyor track 6 .

[0095] A number of trolleys are movably connected to the rail. The trolleys are connected to each other by one or more chain elements (eg chain links, a cable, etc.). In an alternative embodiment, the carriers are not coupled to each other when eg the carriers are temporarily brought into a buffer or similar where the mutual distance can be changed.

[0096] The tray carriers 7 are each suspended from the rails 5 by one or more trolleys. The conveyor system is provided with drive means 9 for displacing the chain of tray carriers 7 along the conveyor track 6 in the conveying direction 10 . The conveyor system is activated by a control system 11 .

[0097] figure 1 The conveyor system 1 described in is configured for conveying various ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com