Injectable depot gel composition and method of preparing the composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0063] Lysozyme particles were made by spray drying 50% sucrose and 50% chicken lysozyme (on a dry weight basis).

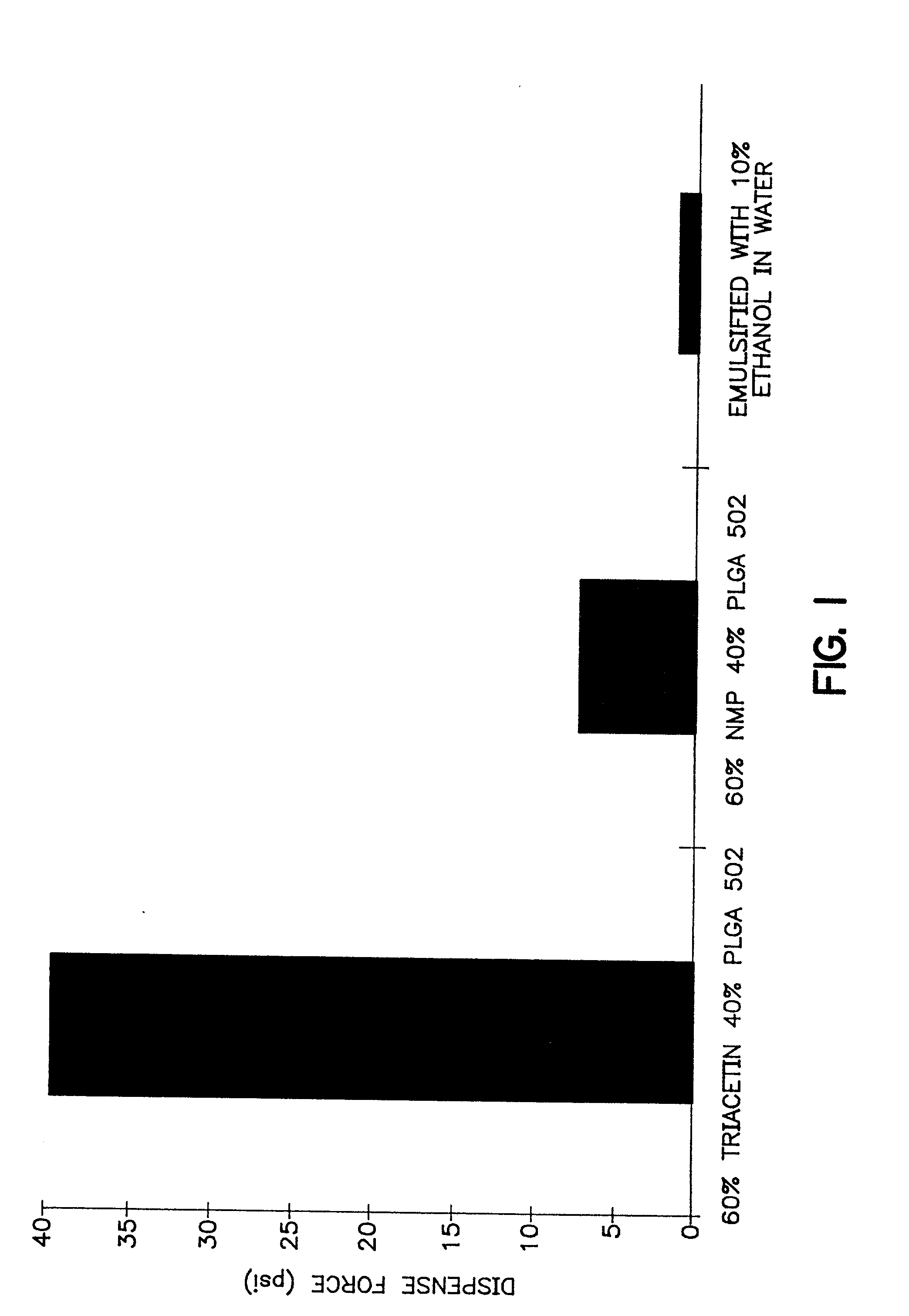

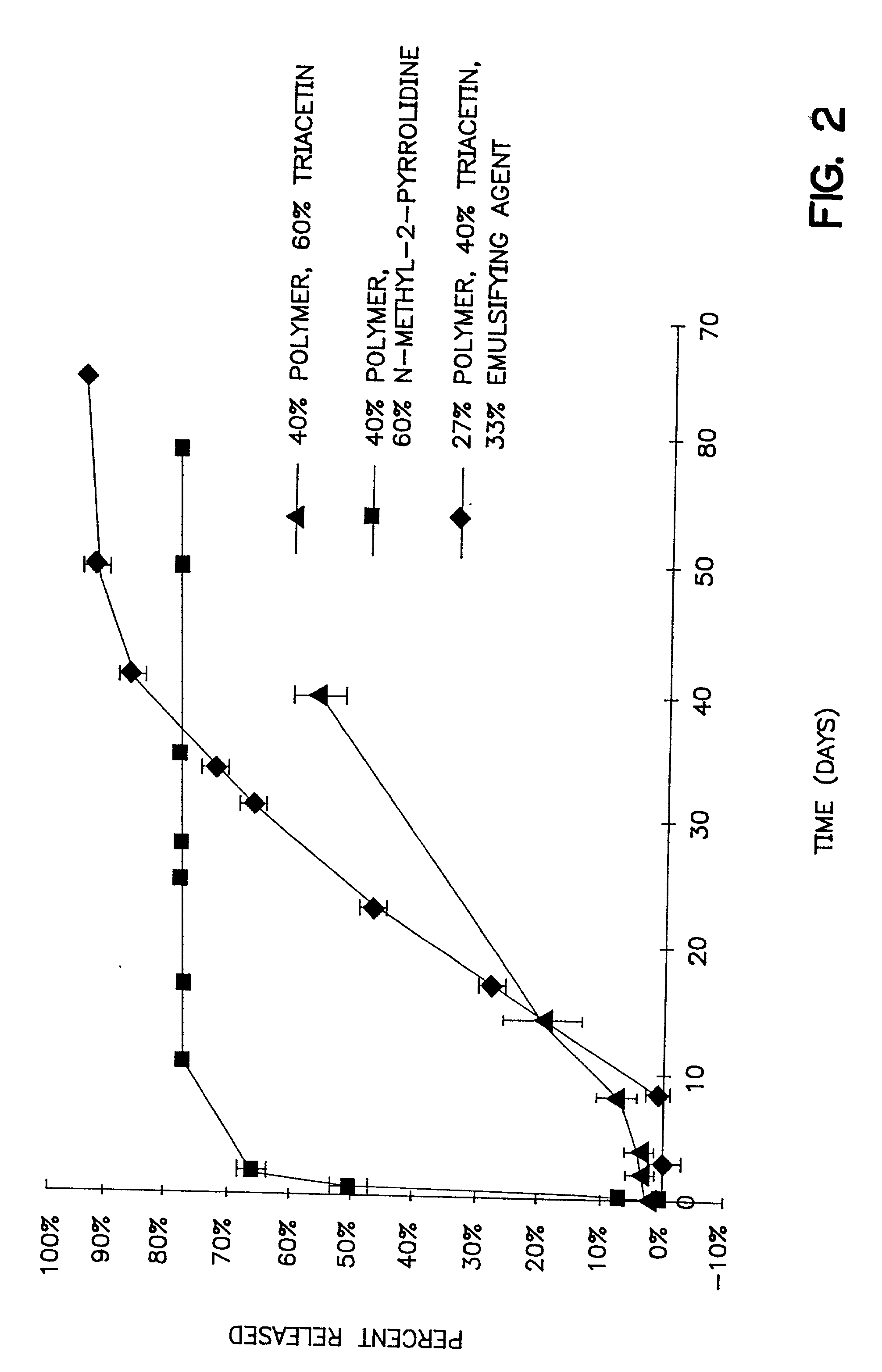

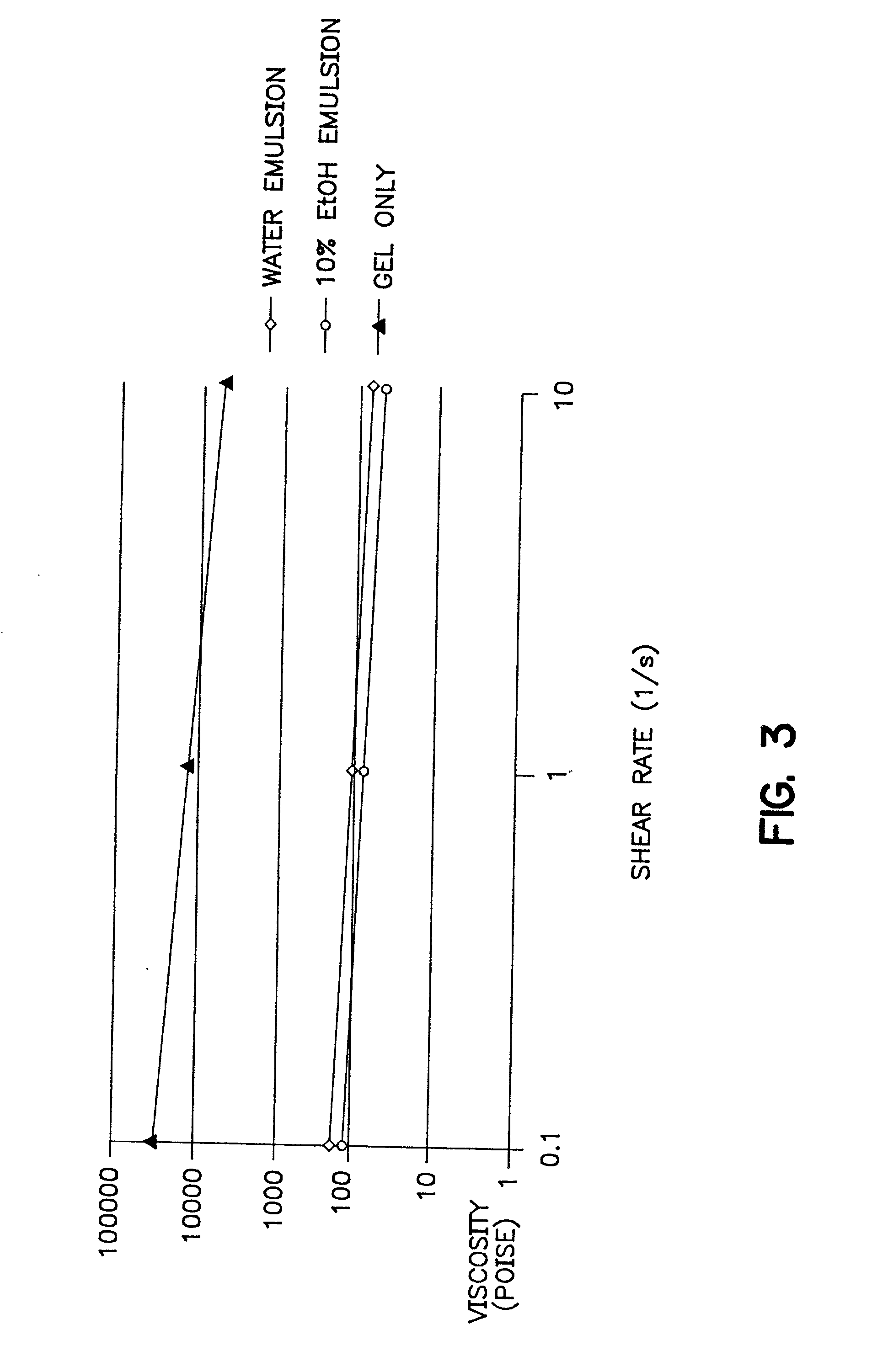

[0064] A viscous gel material was prepared by heating 60% by weight of triacetin with 40% by weight of a 50:50 lactic acid:glycolic acid copolymer to 37.degree. C. overnight. The viscous gel was allowed to cool to room temperature while mixing continued. The lysozyme particles were added to the viscous gel in a ratio of 20:80 lysozyme particles:gel (by weight). The combination was mixed for 5 minutes. Immediately prior to use, a 10% ethanol, 90% isotonic saline solution was added as the emulsifying agent. The emulsifying agent comprised 1 / 3 of the total injectable depot gel composition. 0.5 grams of this injectable depot composition was then injected into a rat.

[0065] In accordance with various aspects of the present invention, one or more significant advantages can be obtained. More specifically, using simple processing steps, one can obtain a depot gel composition that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com