Process of producing small molecular weight polyether amine by continuous method

A low-molecular-weight, polyetheramine technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve the problems of high process conditions, limited yield, decreased catalyst activity, etc., and achieves simple process steps. , the effect of increasing production and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The reaction was carried out in a fixed-bed reactor with continuous feeding, and the reactor included 4 tubular reactors connected in series. The inner diameter of the tubular reactor was 13mm, and each reactor was filled with 100ml of catalyst.

[0020] The tubular reactors are filled with the following catalysts from front to back, the first reactor: Raney metal catalyst, the metal nickel content is 100%, the average particle size is 3mm; the second reactor: the supported metal with alumina as the carrier Catalyst, the particle size is 3mm * 3mm, the loaded metal content (reduction state) is, nickel 30%, copper 10%; The third reactor: the metal supported catalyst with alumina as the carrier, the particle size is 3mm * 3mm, the load The metal content (reduced state) is 25% nickel, 15% copper, and 1.5% chromium; the fourth reactor: a metal-supported catalyst with alumina as a carrier, the particle size is 3mm×3mm, and the loaded metal content (reduced state) For, nickel...

Embodiment 2

[0025] The experimental device is the same as that of Example 1, and the same catalysts are filled in the 4 reactors, all of which are Raney metal catalysts, the metal content is 100% nickel, and the average particle size is 3mm.

[0026] The reaction temperature is 220°C, and the reaction pressure is 13.5Mpa.

[0027] The polyether used is polypropylene glycol ether with an average molecular weight of 230. Liquid ammonia and polyether hydroxyl are mixed at a molar ratio of 60:1, and enter the reactor through a liquid feed pump at a feed rate of 600 g / h and a hydrogen flow rate of 0.45 liter / min.

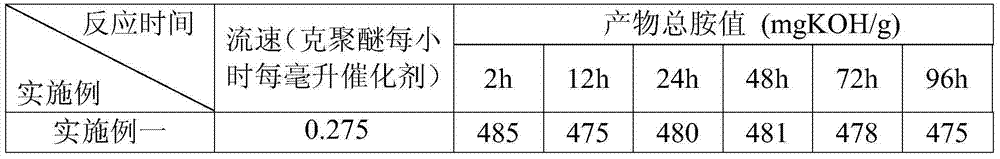

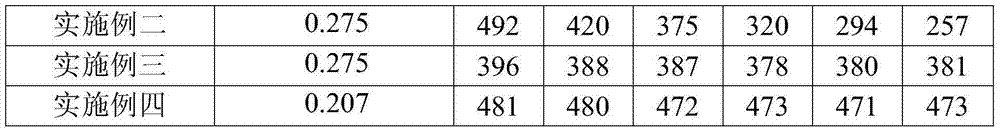

[0028] Table 1 lists the total amine values of the products obtained at different times after the feed is deaminated and dehydrated.

Embodiment 3

[0030] Experimental apparatus is identical with embodiment one, fills identical catalyst in 4 reactors, is the metal supported catalyst that is carrier with alumina, and particle diameter is 3mm * 3mm, and loaded metal content (reduced state) is: nickel 20%, Copper 18%, Ruthenium 1.5%.

[0031] The reaction temperature is 220°C, and the reaction pressure is 13.5Mpa.

[0032] The polyether used is polypropylene glycol ether with an average molecular weight of 230. Liquid ammonia and polyether hydroxyl are mixed according to the molar ratio of 60:1, and then enter the reactor sequentially through the liquid feed pump. 1.25:1.

[0033] Table 1 lists the total amine values of the products obtained at different times after the feed is deaminated and dehydrated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com