Separation and extraction method of microbial oil

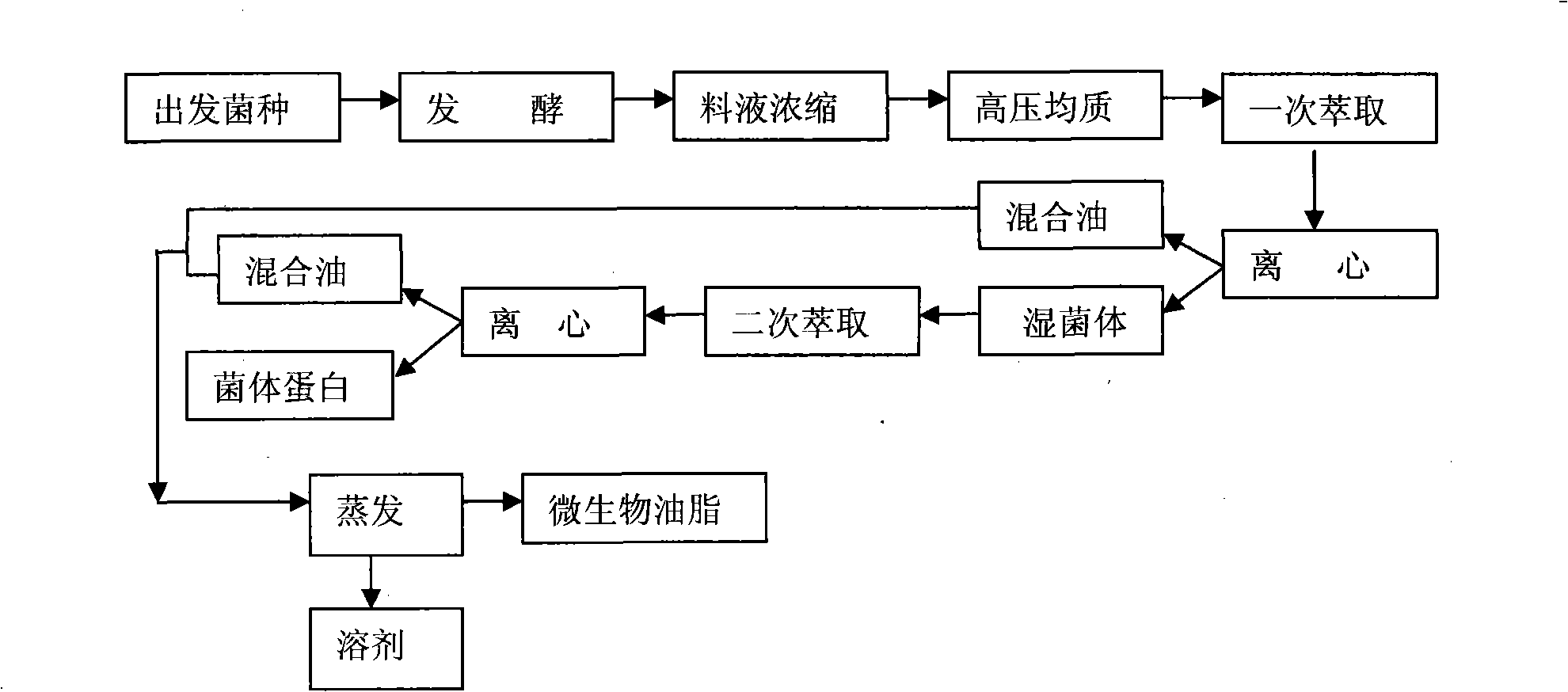

A technology of microbial oil and extraction method, which is applied in the field of microbial oil separation and extraction, can solve the problems of complex production process, low oil yield and high energy consumption, and achieves the effects of simple operation, high oil yield and simplified process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using Candida terrestris as the starting strain, follow the steps below:

[0021] A, first carry out the preparation of secondary seed liquid in shake flask, then inoculate in the 30L fermentor that substratum is housed with prepared seed liquid, fermentation medium composition is yeast powder 15g / L, peptone 15g / L, Glucose 70g / L, cultured at pH 5.6, 30°C, and agitation speed of 250r / min for 7 days under aerobic conditions, and finally obtained the required fermentation broth, in which the biomass was 100g / Kg fermentation broth, containing 0.475g oil / g dry bacteria;

[0022] B, add the 5A type molecular sieve of 2.5Kg / Kg fermented liquid (Tianjin Damao Chemical Reagent Factory) in fermented liquid, remove 50% moisture in the fermented liquid to improve the concentration of thalline under stirring state, leave standstill to isolate molecular sieve , can be reused after drying;

[0023] C. Start the main motor of the high-pressure homogenizer (NS3015H, Niro Soavi Compan...

Embodiment 2

[0027] Using Candida terrestris as the starting strain, follow the steps below:

[0028] A, first carry out the preparation of secondary seed liquid in shake flask, then inoculate in the 30L fermentor that substratum is housed with prepared seed liquid, fermentation medium composition is yeast powder 15g / L, peptone 15g / L, Glucose 70g / L, cultured at pH 5.6, 30°C, and agitation speed of 250r / min for 7 days under aerobic conditions, and finally obtained the required fermentation broth, in which the biomass was 100g / Kg fermentation broth, containing 0.475g oil / g dry bacteria;

[0029] B. Add 2.5Kg / Kg 5A molecular sieve to the fermentation liquid, absorb and concentrate to remove 50% of the water in the fermentation liquid under stirring to increase the concentration of the bacteria, stand to separate the molecular sieve, and reuse it after drying ;

[0030] C. Start the main motor of the homogenizer, slowly rotate the secondary pressure regulating handle to make the final homog...

Embodiment 3

[0034] Using Candida terrestris as the starting strain, follow the steps below:

[0035] A, first carry out the preparation of secondary seed liquid in shake flask, then inoculate in the 30L fermentor that substratum is housed with prepared seed liquid, fermentation medium composition is yeast powder 15g / L, peptone 15g / L, Glucose 70g / L, cultured at pH 5.6, 30°C, and agitation speed of 250r / min for 7 days under aerobic conditions, and finally obtained the required fermentation broth, in which the biomass was 100g / Kg fermentation broth, containing 0.475g oil / g dry bacteria;

[0036] B. Add 2.5Kg / Kg 5A molecular sieve to the fermentation liquid, absorb and concentrate to remove 50% of the water in the fermentation liquid under stirring to increase the concentration of the bacteria, stand to separate the molecular sieve, and reuse it after drying ;

[0037] C. Start the main motor of the homogenizer, slowly turn the secondary pressure regulating handle to make the final homogeniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com