Extraction method for tulip essence

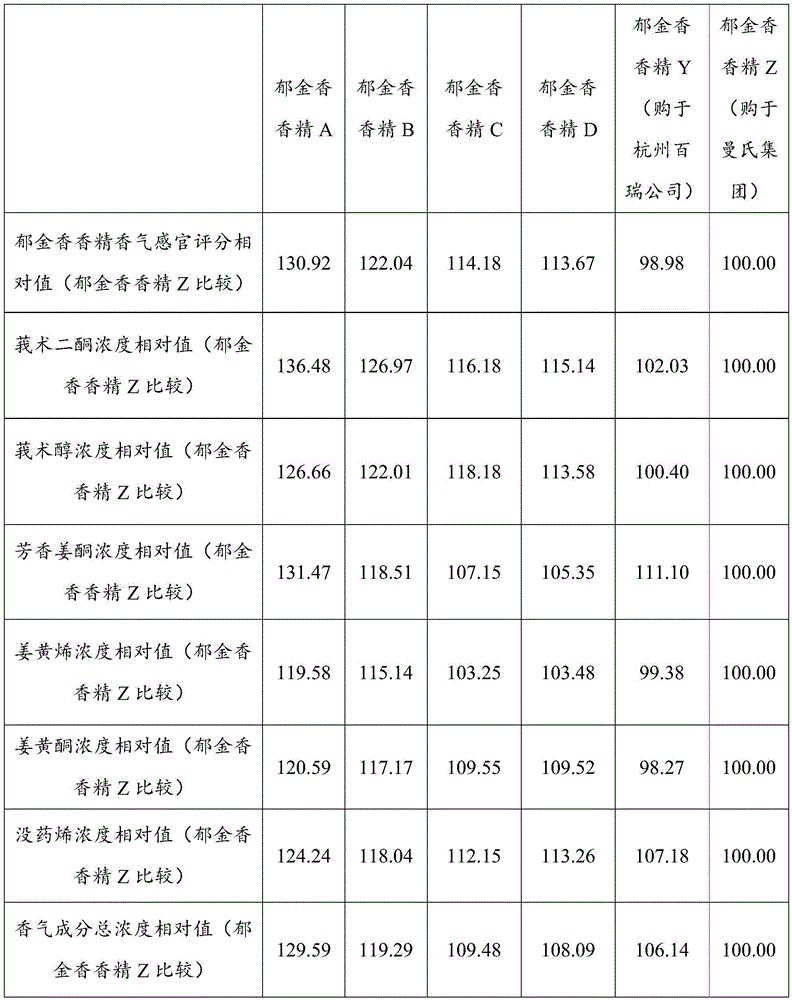

An extraction method, tulip technology, applied in essential oils/fragrances, fat production, etc., can solve the problems of heat-sensitive component damage, aroma sensory quality and concentration of aroma components, and solvent residues, etc., to reduce solvent residues and reduce heat-sensitive components The effect of destroying, increasing the sensory quality of aroma and the concentration of aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 100.0 g of tulip flowers and leaves, preliminarily pulverize them with an ultrafine pulverizer, and then sieve to obtain the first product A with a particle size of 200 mesh. The first product A is dissolved in 4000.0g volume concentration and is in the ethanol aqueous solution of 70%, after soaking and stirring, be pulverized by the high-pressure high-shear micro-jet pulverizer of 100MPa with the micro-jet homogeneous pressure, the micro-jet circulation number is 40 times, The second product A is obtained. The second product A was extracted for 1 hour under the ultrasonic power of 400W, centrifuged at 10000 rpm for 10 minutes, and the supernatant was collected to obtain the third product A. Add 0.5 g of β-N-acetylglucosidase to the third product A, adjust the pH to 6.0, and perform enzymatic hydrolysis at 45° C. for 4 hours to obtain the fourth product A. The fourth product A was distilled under reduced pressure for 2 h under the condition of 0.01 MPa, and the f...

Embodiment 2

[0022] Weigh 100.0 g of tulip flowers and leaves, preliminarily pulverize them with an ultrafine pulverizer, and then sieve to obtain the first product B with a particle size of 300 mesh. The first product B is dissolved in 2000.0g volume concentration and is in the ethanol aqueous solution of 60%, after soaking and stirring, be pulverized by the high-pressure high-shear micro-jet pulverizer of 130MPa with the micro-jet homogeneous pressure, the number of micro-jet cycles is 30 times, The second product B is obtained. The second product B was extracted for 0.5 h under the ultrasonic power of 400 W, centrifuged at 10000 rpm for 10 min, and the supernatant was collected to obtain the third product B. Add 1.0 g of β-N-acetylglucosidase to the third product B, adjust the pH to 6.0, and perform enzymatic hydrolysis at 45° C. for 4 hours to obtain the fourth product B. The fourth product B was distilled under reduced pressure for 2 h under the condition of 0.01 MPa, and the fractio...

Embodiment 3

[0025] Weigh 100.0 g of tulip flowers and leaves, preliminarily pulverize them with an ultrafine pulverizer, and then sieve to obtain the first product C with a particle size of 200 mesh. The first product C is dissolved in 6000.0g volume concentration and is in the ethanol aqueous solution of 60%, after soaking and stirring, be pulverized by the high-pressure high-shear micro-jet pulverizer of 80MPa with the micro-jet homogeneous pressure, the micro-jet circulation number is 60 times, The second product C is obtained. The second product C was extracted for 1 hour under the ultrasonic power of 200W, centrifuged at 10000rpm for 10 minutes, and the supernatant was collected to obtain the third product C. Add 0.5 g of β-N-acetylglucosidase to the third product C, adjust the pH to 6.0, and perform enzymatic hydrolysis at 45° C. for 4 hours to obtain the fourth product C. The fourth product C was distilled under reduced pressure for 2 h under the condition of 0.01 MPa, and the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com