High-quality curcumin product as well as production method and application thereof

A technology of curcumin and curcumin extract, applied in the field of high-quality curcumin products, can solve the problem of improving solvent residue and crystal bulk density, fluidity, affecting crystal physicochemical properties, undisclosed crystallization process crystal product physicochemical properties, etc. problems, to achieve the effects of easy large-scale production, improved fluidity, and reduced solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Dissolving: get 100 g of turmeric extract raw material whose solvent residue is 5% (mass fraction), add 100 ml of n-butanol, heat up to 115° C., stir and dissolve;

[0041]Reflux: Introduce carbon dioxide at 117°C, and start to cool down after reflux for 0.5h;

[0042] Cooling and crystallization: the refluxed solution is cooled and stirred for crystallization, the stirring speed is 100r / min, and the temperature is lowered to 40°C and then kept for 48h;

[0043] Separation and drying: After the crystallized feed liquid is suction-filtered, the curcumin crystal semi-finished product is obtained, and the curcumin crystal semi-finished product is dried to obtain high-quality curcumin.

[0044] Through the production method of above-mentioned high-quality curcumin, the curcumin that obtains dissolves residue is 48ppm, and the fluidity of curcumin is 2.5s / g, and bulk density is 0.32g / ml, and curcumin content is 90.3%.

Embodiment 2

[0046] Dissolving: get 200 g of turmeric extract raw material with solvent residue of 1% (mass fraction), add 400 ml of propylene glycol, heat up to 150° C., stir and dissolve;

[0047] Reflux: Inject carbon dioxide at 150°C and start to cool down after heating for 1 hour;

[0048] Cooling and crystallization: the refluxed solution is cooled and stirred for crystallization, the stirring speed is 50r / min, and the temperature is lowered to 30°C and then kept for 24h;

[0049] Separation and drying: After the crystallized feed liquid is suction-filtered, the curcumin crystal semi-finished product is obtained, and the curcumin crystal semi-finished product is dried to obtain high-quality curcumin.

[0050] Through the production method of above-mentioned high-quality curcumin, the curcumin residue that obtains is 42ppm, and the fluidity of curcumin is 2.0s / g, and bulk density is 0.37g / ml, and curcumin content is 93.7%.

Embodiment 3

[0052] Dissolution: Take 150g of the turmeric extract raw material with a solvent residue of 5000ppm, add 1500ml of ethanol, heat up to 78°C, and stir to dissolve;

[0053] Reflux: Introduce nitrogen gas at 75°C, and start to cool down after reflux for 2 hours;

[0054] Cooling and crystallization: the refluxed solution is cooled and stirred for crystallization, the stirring speed is 30r / min, and the temperature is lowered to 20°C and then kept for 12h;

[0055] Separation and drying: After the crystallized feed liquid is suction-filtered, the curcumin crystal semi-finished product is obtained, and the curcumin crystal semi-finished product is dried to obtain high-quality curcumin.

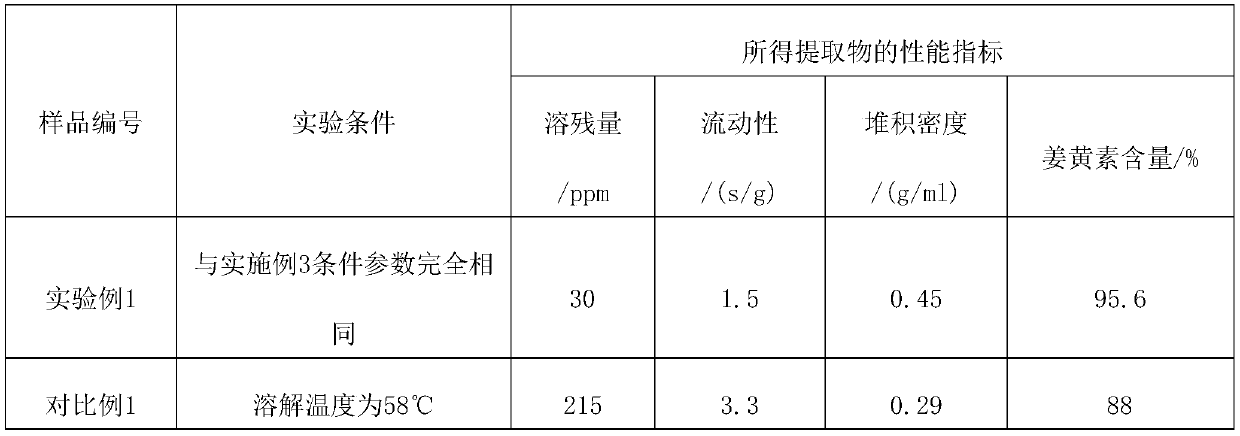

[0056] Through the production method of above-mentioned high-quality curcumin, the curcumin residue that obtains is 30ppm, and the fluidity of curcumin is 1.5s / g, and bulk density is 0.45g / ml, and curcumin content is 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com