Method for recovering acetone from dilute acetone water solution by reduced-pressure steam stripping type rectification

An acetone aqueous solution and stripping technology, which is applied in the field of acetone recovery, can solve the problems of high energy consumption, capital construction equipment and operating costs, and achieve the effects of reducing capital construction and equipment costs, height, and rectification operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

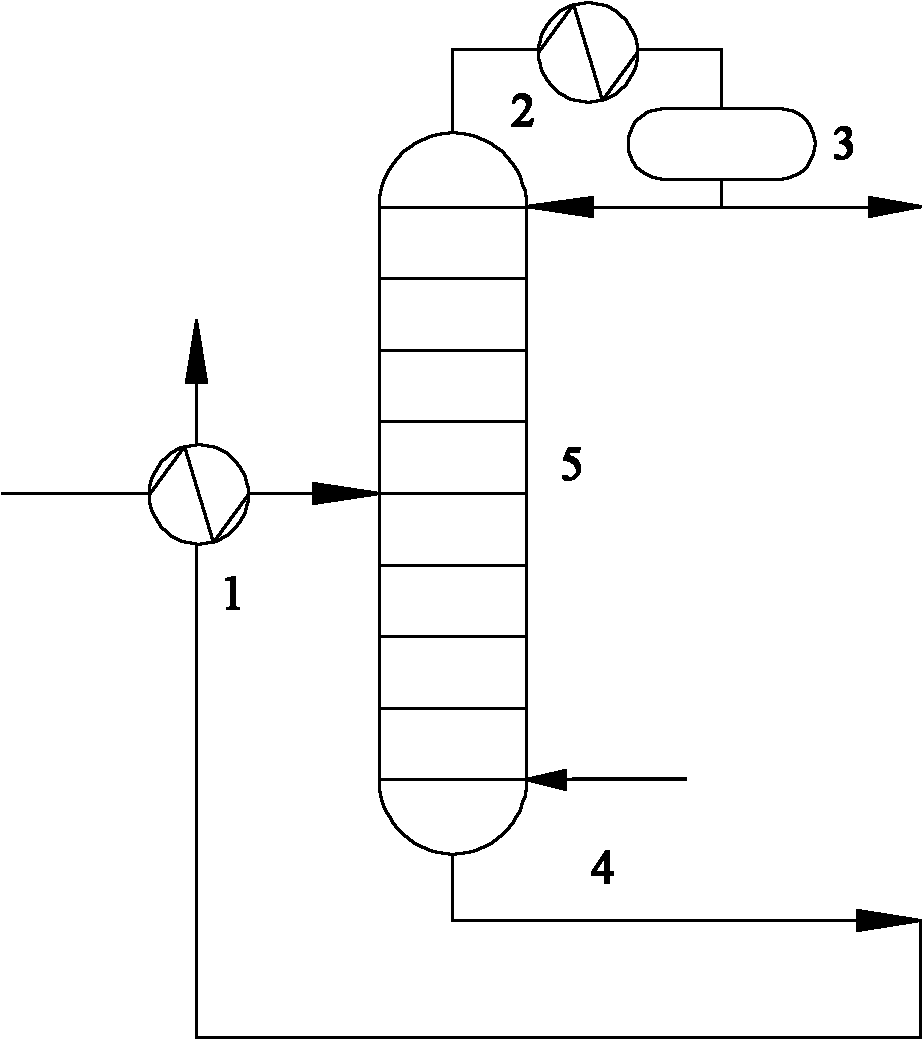

Embodiment 1

[0022] The acetone-water solution with a flow rate of 100t / hr and a mass concentration of acetone of 10% is exchanged through the heat exchanger 1 and the discharge liquid of the tower kettle 4, and the allycetone-water solution is heated to 92°C. Enter in the rectifying tower under the situation, the tray number of rectifying tower 5 is 21, and feed position is 11 # At the tray; the steam (98.5% acetone, 1.5% water) with a temperature of 53.6°C at the top of the tower is condensed to 40°C through the condenser 2 and enters the liquid storage tank 3, and a part of it (98.5% acetone, 1.5% water) is used as the tower The top product is collected, and another part is refluxed in the rectifying tower as reflux liquid, and wherein mass reflux ratio (product amount / reflux flow rate) is 1.5: 1, and the operating pressure of tower top is 0.09MPa; Rectifying tower 5 adopts stripping type Direct steam heating, the superheated steam with a flow rate of 7.760t / hr, a temperature of 172°C a...

Embodiment 2、3

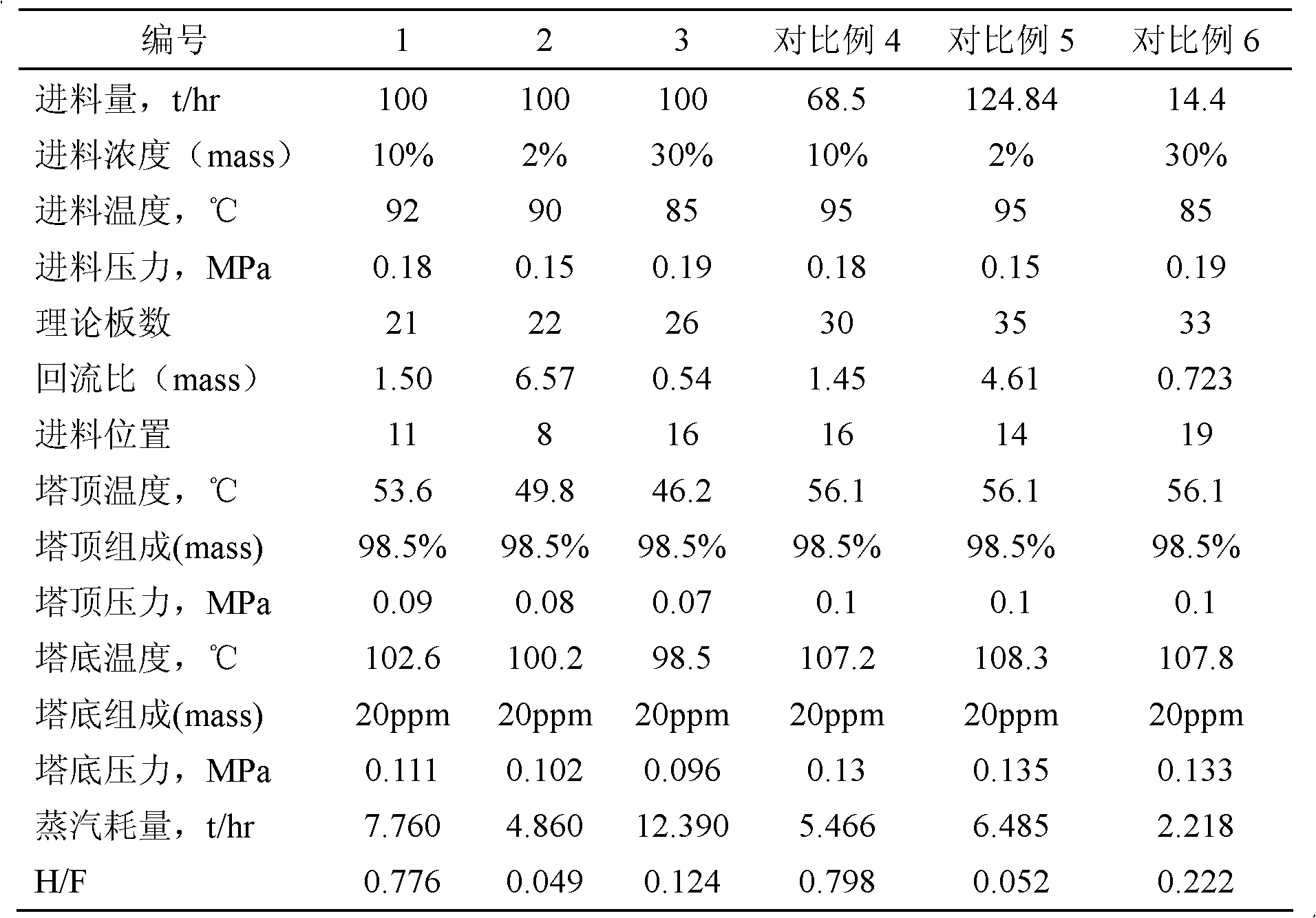

[0024] The treatment method of Examples 2-3 is the same as that of Example 1, and the process parameters are shown in Table 1; Comparative Examples 4, 5, and 6 are respectively comparative examples of Examples 1, 2, and 3, and the process parameters are shown in Table 1.

[0025] Comparative examples 4, 5, and 6 in Table 1 are operation examples using conventional rectification (atmospheric pressure, reboiler heating) operation and the presence of a constant concentration zone. As can be seen from Table 1, the vacuum stripping rectification operation can significantly reduce the steam consumption compared with the conventional rectification operation; Compared with the distillation operation, the number of theoretical plates is reduced by 9-13 blocks, which can greatly reduce the construction cost of the distillation tower.

[0026] Table 1

[0027]

[0028] Remarks: H / F=steam consumption (t / hr) / feed amount (t / hr)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com