Preparation technique of high-purity scutellarin raw medicine

A technology of scutellarin and scutellarin, which is applied in the field of preparation of scutellarin raw materials, can solve problems that cannot be solved well, and achieve the effects of being beneficial to environmental protection, increasing content, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

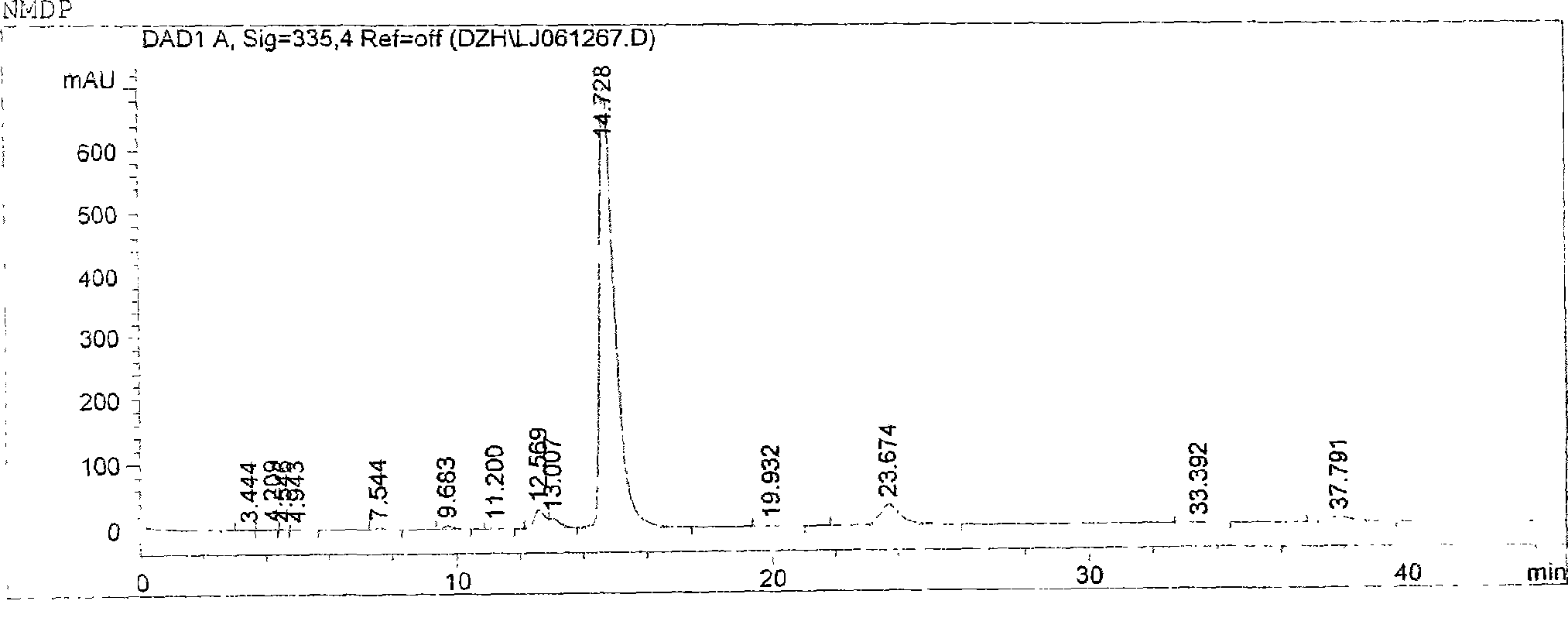

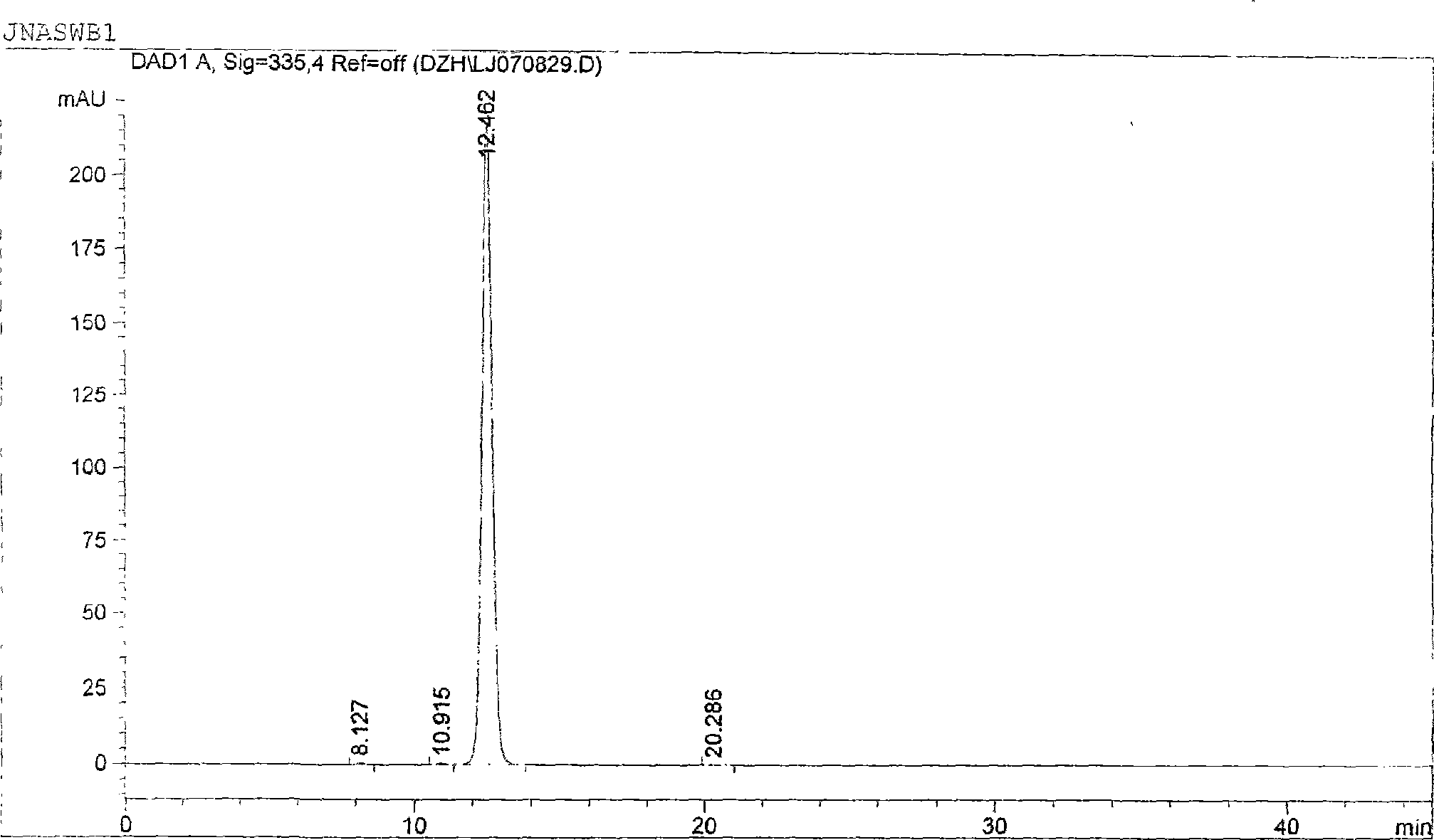

Image

Examples

Embodiment 1

[0024] Weigh 1000g of commercially available scutellarin, wherein the content of scutellarin is 86%, put it in a stainless steel barrel, add boiling water to prepare a concentration of 20% by weight, stir well, and adjust the pH value to 7 with 20% sodium bicarbonate , to dissolve, the filtrate was first centrifuged by a 16000rpm continuous tube centrifuge, and then filtered, the filtrate was added to the D101 macroporous resin column, water was used as the eluent, and the eluate was collected until it was basically colorless. The eluent was concentrated to 1 / 20 of the original volume, 10 times the volume of acetone was added, stirred, allowed to stand for 10 hours, precipitated, filtered, and the mother liquor in the precipitate was washed with acetone to obtain scutellarin salt.

[0025] Move the obtained scutellarin salt into another container, add 8 times the volume of 50% acetone aqueous solution, stir well, adjust the pH to 1 with 10% hydrochloric acid, let it stand for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com