Production method for continuous synthesizing vinylmethylketone by one-step and device thereof

A production method and a technology for butenone, which are applied in the field of production methods and equipment for one-step continuous synthesis of butenone, can solve the problems of high pressure resistance and anti-leakage requirements of production equipment, low equipment production capacity, and great potential safety hazards, and the like, Achieve the effect of low raw material consumption and energy consumption, large equipment production capacity, and low circulation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

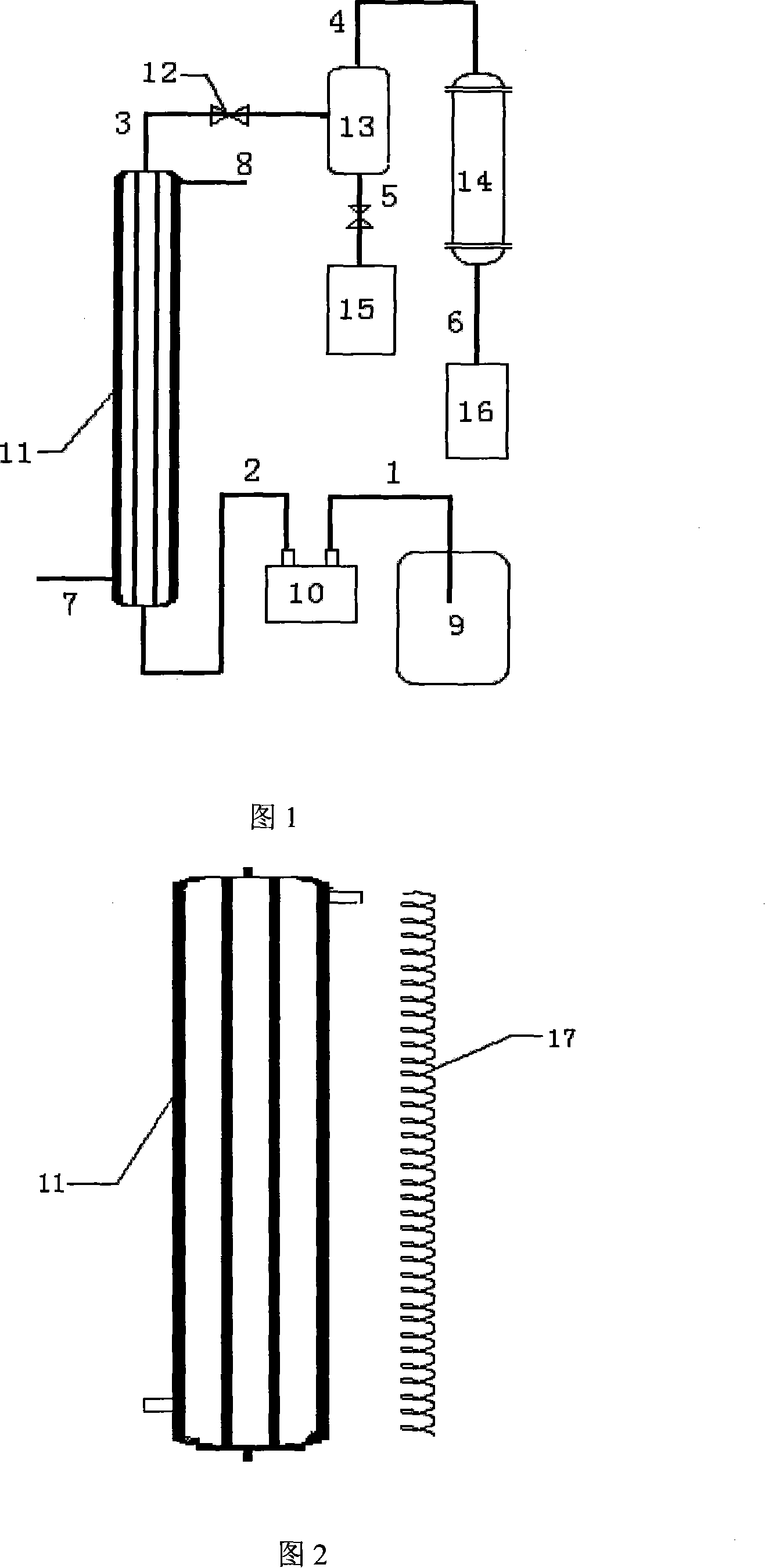

Method used

Image

Examples

Embodiment 1

[0021] Mix 100 parts of formaldehyde, 600 parts of acetone and 2 parts of sulfuric acid, and put them into the raw material tank. Use a metering pump to continuously feed it into the reactor at a rate of 300ml / h. The temperature of the heat transfer oil in the reactor casing is controlled at 225°C. The butenone content of the liquid phase and vapor phase condensate was analyzed after flash evaporation of the outflow of the reaction liquid, and the yield of butenone was calculated to be 81%.

Embodiment 2

[0023] The process of embodiment 2 is the same as that of embodiment 1, except that the raw material ratio is 100 parts of formaldehyde, 700 parts of acetone and 3 parts of sulfuric acid. The reaction tube is equipped with a helical conduction stainless steel wire. Butenone yield was 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com