Plant antimicrobial paint

A plant antibacterial and coating technology, applied in the field of coatings, can solve the problems of poor persistence of inorganic antifungal agents, aging and decomposition of organic antifungal agents, and affecting the film-forming properties of coatings, achieving excellent application value, long shelf life, and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 camphor tree leaf extract

[0022] The fresh leaves of camphor tree were collected in September-October, dried at 45°C for 10 hours, crushed, sieved, and dry powder was obtained.

[0023] Weigh 50kg of dry powder, put it into a Soxhlet extraction tank, add 1000kg of acetone aqueous solution with a volume fraction of 50%, and extract under reflux at about 80°C for 8 hours to obtain an extract.

[0024] The extract is distilled, and the solvent is recovered for reuse until the residue of the extract is in the form of extract.

[0025] Combine the distillates of extracts prepared several times, and freeze-dry to obtain about 30 kg of camphor tree leaf extract.

Embodiment 2

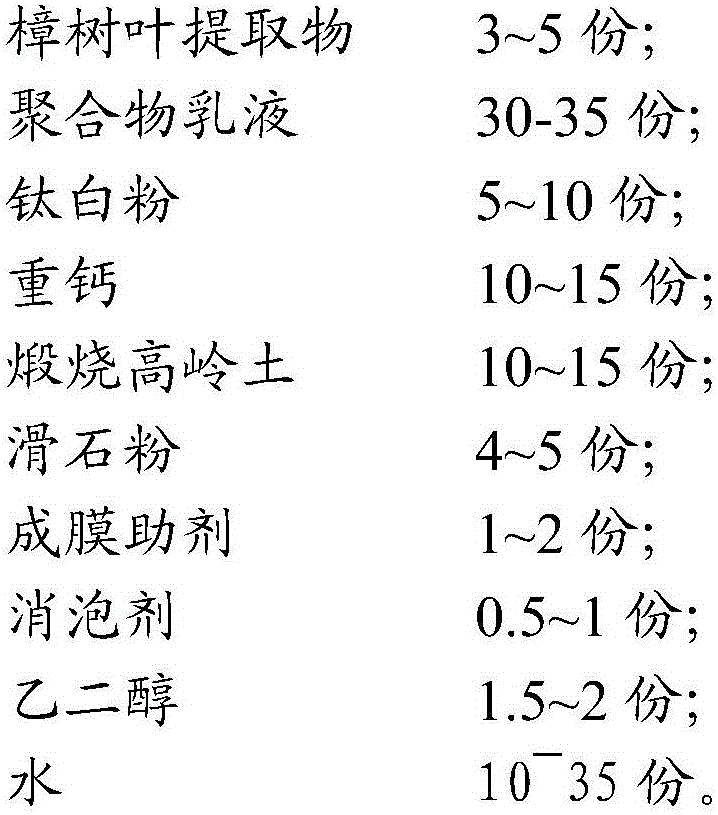

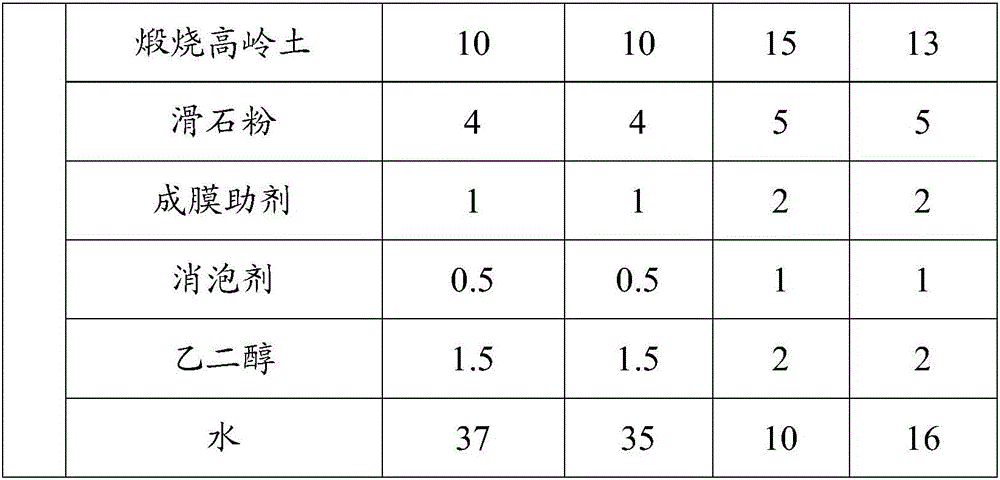

[0026] The preparation of embodiment 2 plant antibacterial coatings A~D

[0027] According to each group in Table 1, different plant antibacterial coatings A~D were prepared.

[0028] Table 1 Allocation table of each component of plant antibacterial coating

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com