Energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system

A purification process, energy saving and environmental protection technology, applied in the direction of waste heat treatment, climate sustainability, combustion technology mitigation, etc., can solve the problems of low utilization rate of waste heat from sintering waste gas, no graded utilization of sintering waste gas, and high cost of waste gas purification, so as to improve waste heat Effects of utilization efficiency, emission reduction, and fuel consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

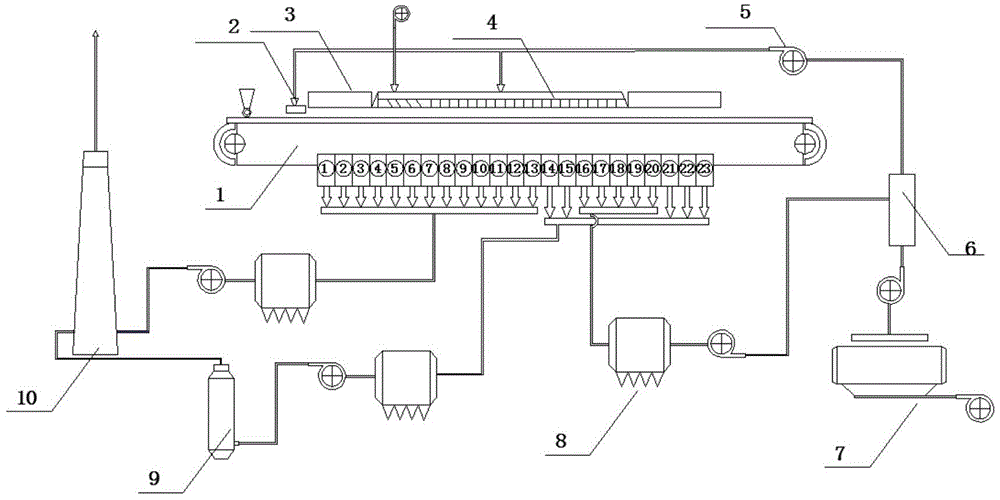

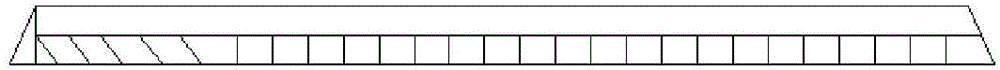

[0055] Such as figure 1 As shown, the flow of hot air is controlled by adjusting the valve of the waste heat pipeline, and the oxygen enrichment level is adjusted so that the sintering waste gas extracted by the bellows is divided into three levels. Counting from the igniter at the head of sintering machine 1, ①- No. bellows is a low-temperature and low-sulfur section, Medium temperature and high sulfur section, It is a high temperature medium sulfur section. Lead out through the pipeline ①- The sintering exhaust gas of the low-temperature and low-sulfur section of the wind box, The sintering waste gas in the medium temperature and high sulfur section of the No. 2 bellows, and the sintering waste gas in the low temperature and low sulfur section are introduced into the dust removal device through the induced draft fan for dust removal. After dust removal, the sulfur content is lower than the national emission standard and is directly discharged into the atmosphere. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com