Polyester fabric moisture absorbing, sweat releasing and heat conducting finishing method based on click chemistry

A technology of click chemical reaction and polyester fabric, which is applied in the field of functional finishing of polyester fabric, can solve the problems of complex process, poor fabric feel, high energy consumption, etc., and achieve the effect of simple operation, no impact on strength, and improved wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

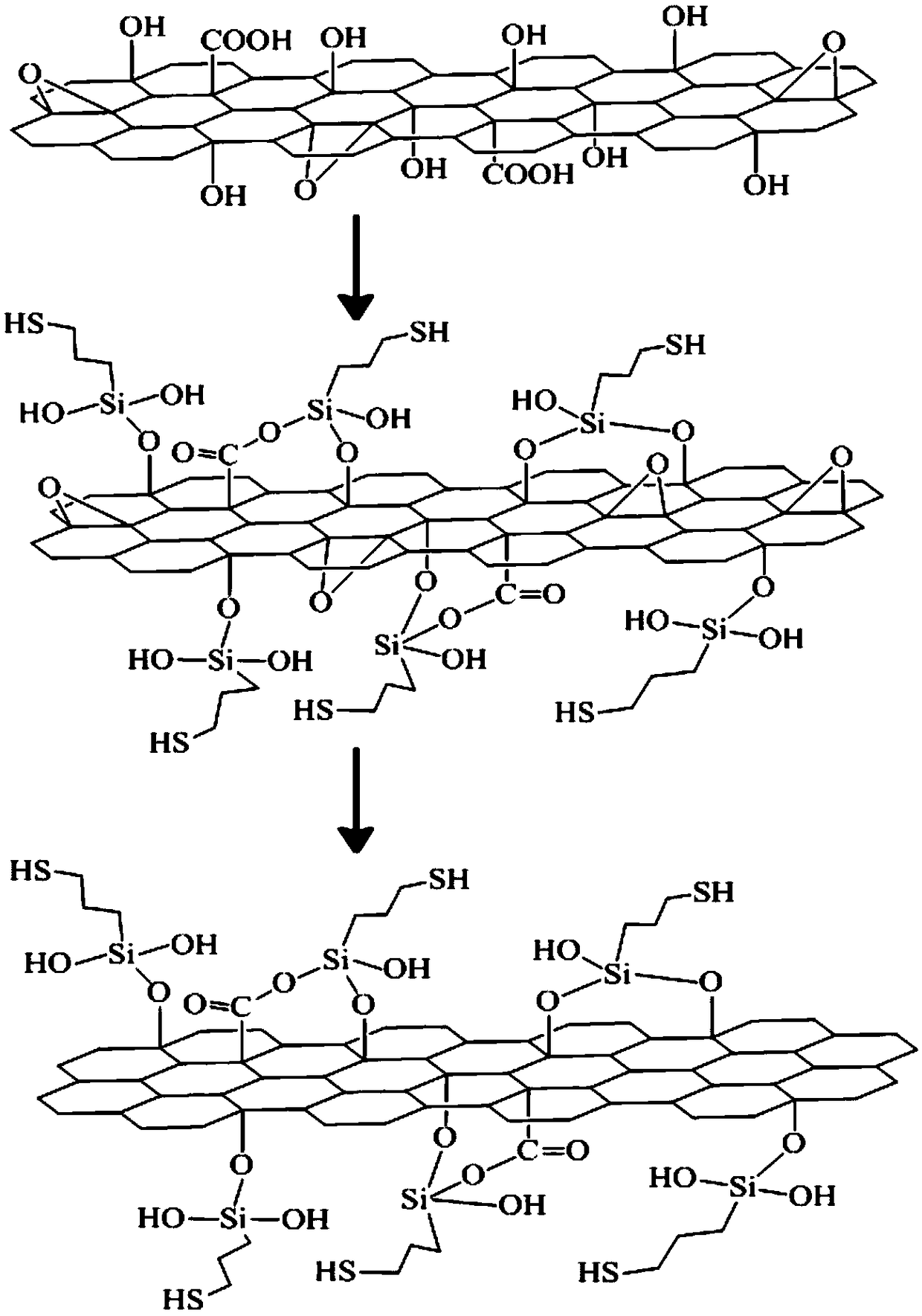

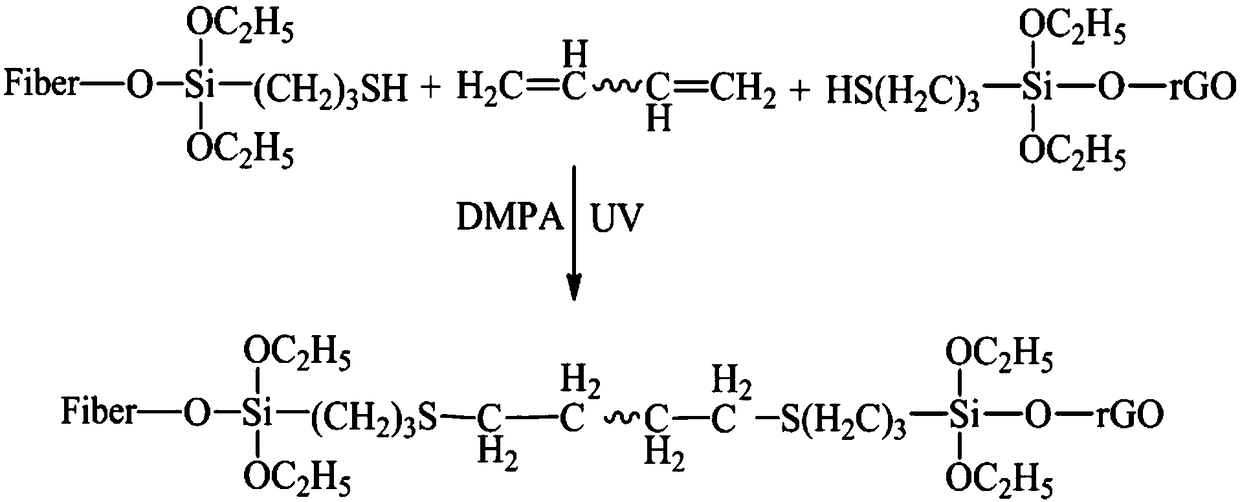

[0041] Use 3-mercaptopropyltriethoxysilane KH-580 to modify polyester fabric and graphene oxide, and react with polyurethane moisture-absorbing and sweat-wicking finishing agent, so that polyester has good moisture-wicking and heat-conducting functions. The specific steps are:

[0042] (1) Finishing agent synthesis:

[0043] Use 5ml of acetone as solvent, 1% dibutyltin dilaurate (DBTDL) as catalyst, 0.01mol PEG-400, 0.02mol isocyanoethyl methacrylate at 80°C for 5 hours with mechanical stirring to obtain polyurethane moisture-wicking finishing agent.

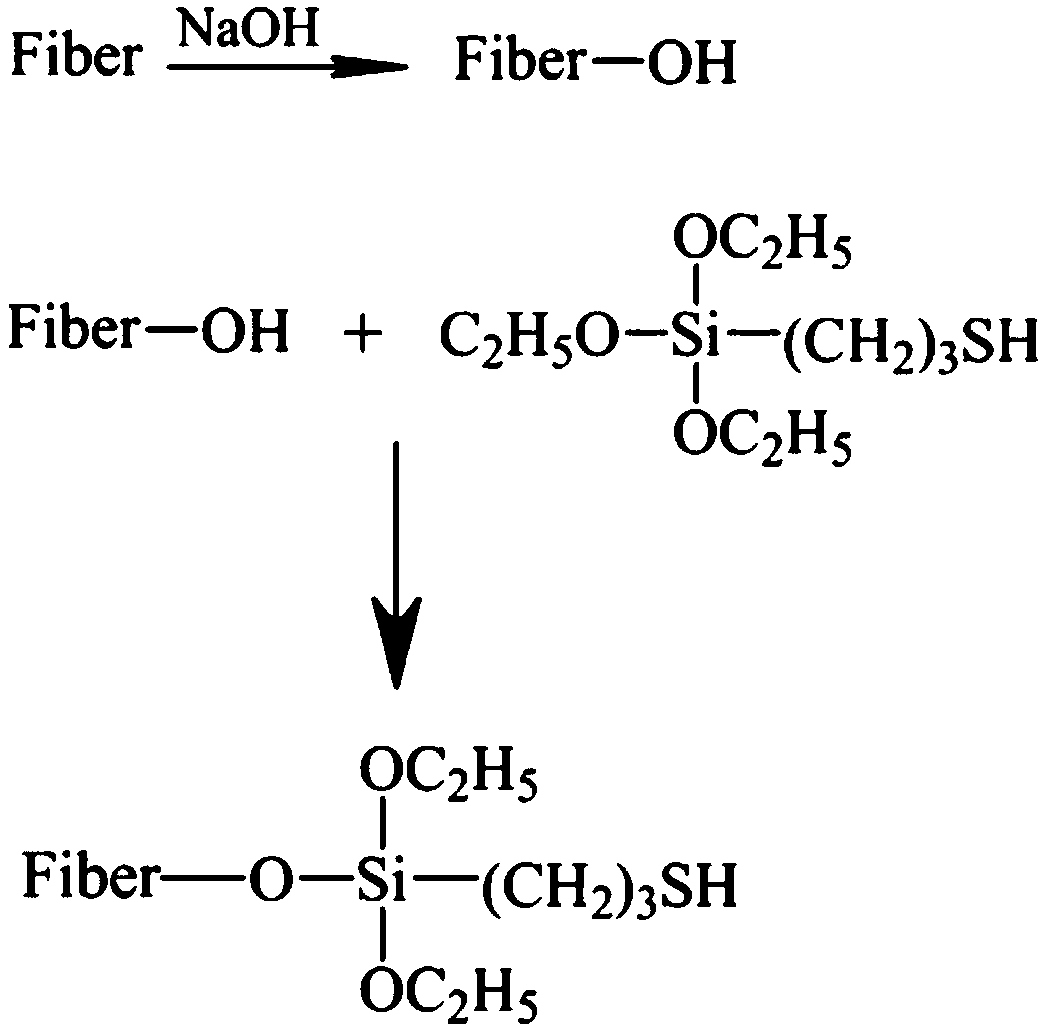

[0044] (2) Fabric pretreatment:

[0045] ① Alkali weight reduction: Prepare 90g / L sodium hydroxide, 5g / L Pingping plus O mixed solution, and carry out alkali weight reduction on polyester fabrics for 45 minutes at 70°C;

[0046] ② Mercapto modification: prepare 5wt% 3-mercaptopropyltriethoxysilane (KH-580) mixed solution of ethanol / water (volume ratio 4:1), pH is 3-4, temperature is 25°C, Put 1 g of alkali-reduced polyester ...

Embodiment 2

[0055] Use 3-mercaptopropyltriethoxysilane KH-580 to modify polyester fabric and graphene oxide, and react with polyurethane moisture-absorbing and sweat-wicking finishing agent, so that polyester has good moisture-wicking and heat-conducting functions. The specific steps are:

[0056] (1) Finishing agent synthesis:

[0057] Use 5ml of acetone as solvent, 1% dibutyltin dilaurate (DBTDL) as catalyst, 0.01mol PEG-400, 0.02mol isocyanoethyl methacrylate at 80°C for 5 hours with mechanical stirring to obtain polyurethane moisture-wicking finishing agent.

[0058] (2) Fabric pretreatment:

[0059] ① Alkali weight reduction: Prepare 90g / L sodium hydroxide, 5g / L Pingping plus O mixed solution, and carry out alkali weight reduction on polyester fabrics for 45 minutes at 70°C;

[0060] ② Mercapto modification: prepare 5wt% 3-mercaptopropyltriethoxysilane (KH-580) mixed solution of ethanol / water (volume ratio 4:1), pH is 3-4, temperature is 25°C, Put 1 g of alkali-reduced polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface temperature | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com