Click chemistry-based cotton fabric durable anti-crease finishing method

A click chemistry, anti-wrinkle finishing technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of lack of research on the durability and anti-wrinkle finishing of cotton fabrics, and achieve the effect of improving wearability, environmental protection and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

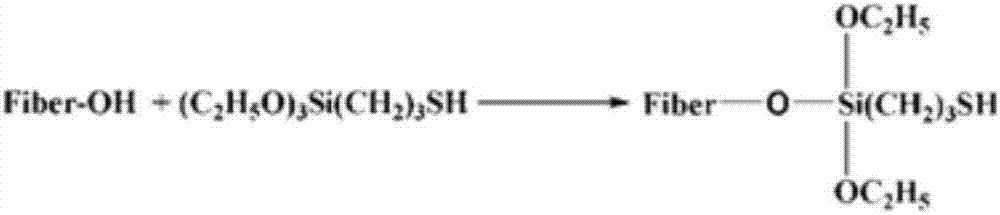

[0035] Use 3-mercaptopropyltriethoxysilane KH-580 to modify cotton fabric, and react with water-based photocurable polyurethane acrylate to make cotton have good anti-wrinkle function. The specific steps are:

[0036] (1) Pre-processing:

[0037] ① Prepare a mixed solution of 20g / L sodium hydroxide and 5g / L Pingping plus O, and roughen the cotton fabric for 45 minutes at 70°C;

[0038] ② Prepare 5 wt% ethyl acetate solution of 3-mercaptopropyltriethoxysilane (KH-580), put the roughened cotton fabric into the above solution, and shake at 30°C for 3 hours;

[0039] ③Take out the cotton fabric, wash it with distilled water, and dry it under vacuum at 60°C.

[0040] (2) Finishing:

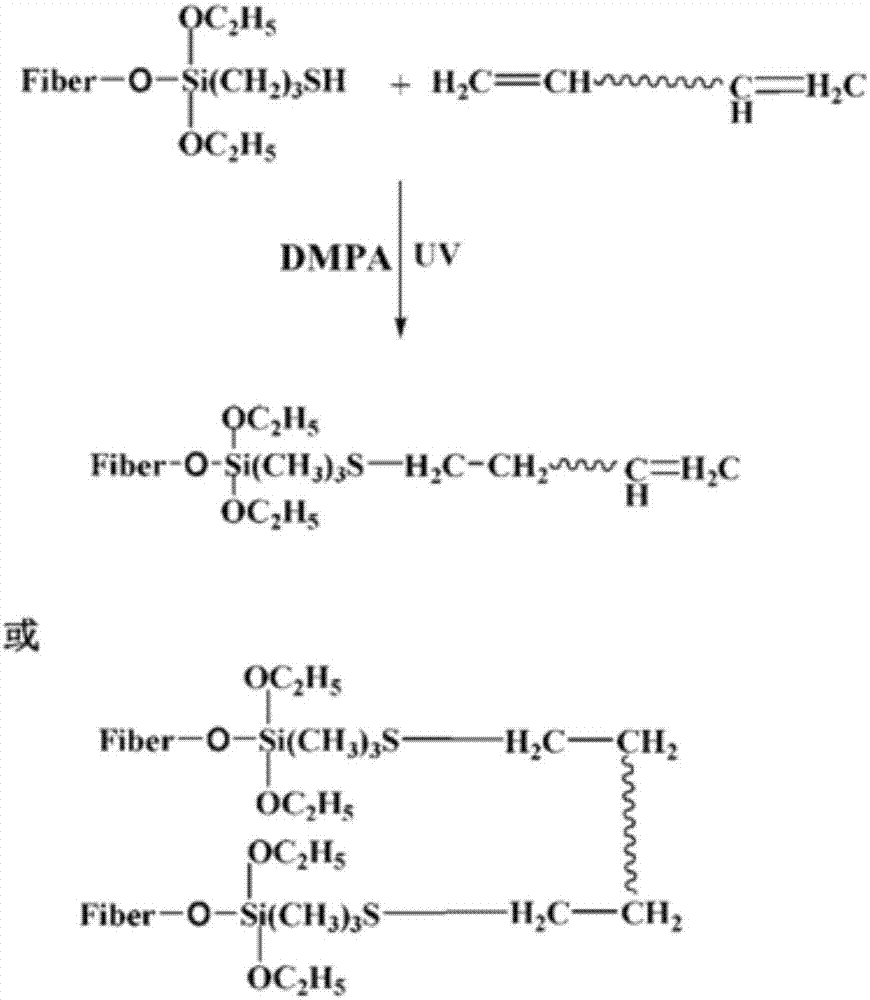

[0041] ① Prepare a mixed solution of 5wt% water-based polyurethane acrylate and 5wt% 3-mercaptopropyltriethoxysilane, ultrasonically oscillate, then add 1wt% photoinitiator, and ultrasonically oscillate;

[0042] ②Put the cotton fabric flatly in the above finishing solution, with a bath ratio of 1:50,...

Embodiment 2

[0044] Use 3-mercaptopropyltriethoxysilane KH-580 to modify cotton fabric, and react with water-based photocurable polyurethane acrylate to make cotton have good anti-wrinkle function. The specific steps are:

[0045] (1) Pre-processing:

[0046] ①Prepare 20g / L sodium hydroxide aqueous solution, 5g / L Pingping plus O, and roughen the cotton fabric for 45min at 70°C;

[0047] ② Prepare 5 wt% ethyl acetate solution of 3-mercaptopropyltriethoxysilane (KH-580), put the roughened cotton fabric into the above solution, and shake at 30°C for 3 hours;

[0048] ③Take out the cotton fabric, wash it thoroughly in distilled water, and dry it under vacuum at 60°C.

[0049] (2) Finishing:

[0050] ① Prepare a mixed solution of 10wt% water-based polyurethane acrylate and 5wt% 3-mercaptopropyltriethoxysilane, fully ultrasonically oscillate, then add 1wt% photoinitiator, and ultrasonically oscillate;

[0051] ②Put the cotton fabric flatly in the above finishing solution, with a bath ratio of...

Embodiment 3

[0053] Use 3-mercaptopropyltriethoxysilane KH-580 to modify cotton fabric, and react with water-based photocurable polyurethane acrylate to make cotton have good anti-wrinkle function. The specific steps are:

[0054] (1) Pre-processing:

[0055] ①Prepare 20g / L sodium hydroxide aqueous solution, 5g / L Pingping plus O, and roughen the cotton fabric for 45min at 70°C;

[0056] ② Prepare 5 wt% ethyl acetate solution of 3-mercaptopropyltriethoxysilane (KH-580), put the roughened cotton fabric into the above solution, and shake at 30°C for 3 hours;

[0057] ③Take out the cotton fabric, wash it thoroughly in distilled water, and dry it under vacuum at 60°C.

[0058] (2) Finishing:

[0059] ① Prepare a mixed solution of 15wt% water-based urethane acrylate and 5wt% 3-mercaptopropyltriethoxysilane, fully ultrasonically oscillate, then add 1wt% photoinitiator, and ultrasonically oscillate;

[0060] ②Put the cotton fabric flatly in the above finishing solution, with a bath ratio of 1:5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com