High-frequency high-speed flexible copper-clad plate and preparation method thereof

A flexible copper-clad laminate, high-speed technology, applied in the field of high-frequency high-speed flexible copper-clad laminate and its preparation, can solve the problems of poor heat resistance, poor dielectric constant stability, large loss, etc., achieve energy saving and environmental protection of the process, and improve product performance , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

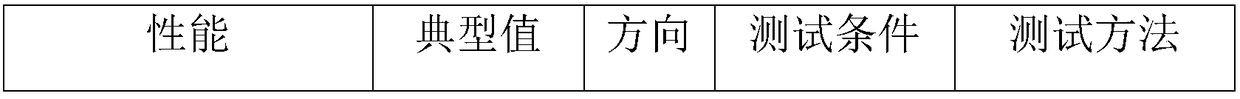

Embodiment 1

[0025] (1) Preparation of surface-treated ceramic powder:

[0026] ① Mix 80 parts by mass of silicon dioxide, 15 parts by mass of aluminum oxide and 5 parts by mass of titanium dioxide to obtain ceramic powder, then add it into distilled water and stir evenly;

[0027] ② Add the silane coupling agent to the ceramic powder distilled water mixture and stir evenly; wherein the mass ratio of the silane coupling agent to the ceramic powder is 5:95;

[0028] ③ drying, crushing and sieving the above mixed solution to obtain surface-treated ceramic powder;

[0029] The particle size D90 of the obtained surface-treated ceramic powder is 2 microns, and the temperature coefficient of dielectric constant is +50ppm / °C.

[0030] (2) Preparation of modified polytetrafluoroethylene powder:

[0031] Using a ball grinding sand mill, 30 parts by mass of surface-treated ceramic powder and 70 parts by mass of dispersed polytetrafluoroethylene powder are uniformly mixed to obtain modified polytet...

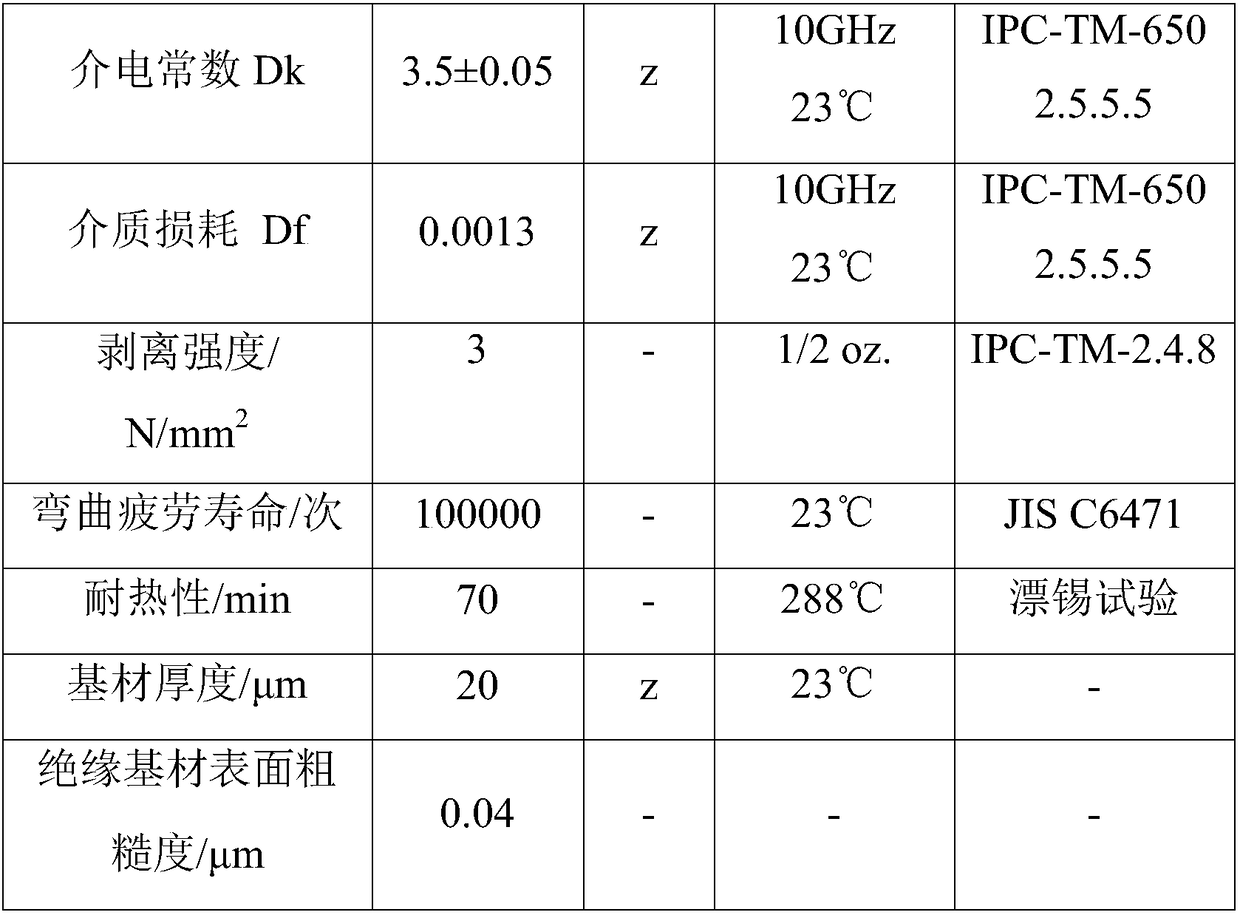

Embodiment 2

[0039] (1) Preparation of surface-treated ceramic powder:

[0040] ① Mix 80 parts by mass of silicon dioxide, 18 parts by mass of aluminum oxide and 2 parts by mass of titanium dioxide to obtain ceramic powder, then add it into distilled water and stir evenly;

[0041] ② Add the silane coupling agent to the ceramic powder distilled water mixture and stir evenly; wherein the mass ratio of the silane coupling agent to the ceramic powder is 5:95;

[0042] ③ drying, crushing and sieving the above mixed solution to obtain surface-treated ceramic powder;

[0043] The particle size D90 of the obtained surface-treated ceramic powder is 2 microns, and the temperature coefficient of dielectric constant is +80ppm / °C.

[0044] (2) Preparation of modified polytetrafluoroethylene powder:

[0045] Using a ball grinding sand mill, 10 parts by mass of surface-treated ceramic powder and 90 parts by mass of dispersed polytetrafluoroethylene powder are uniformly mixed to obtain modified polytet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com