Rubber particle sound-insulation and vibration-damping cast-in-place floor construction method

A technology of rubber particles and construction method, applied in the direction of insulation layer, etc., can solve the problems of high cost of sound insulation materials, limited sound insulation effect, complex construction process, etc., and achieve the effect of saving building space, reducing construction cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments.

[0031] 1. Clean up the base of the floor

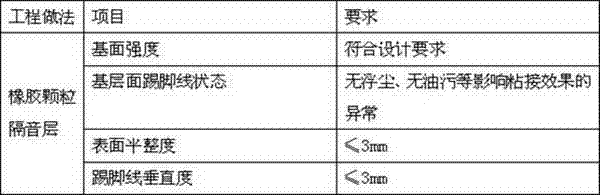

[0032] 1.1) Level the base of the floor to ensure that the concrete strength meets the design requirements, the flatness of the base surface is ±3mm, and the wall skirting height is 120mm; see Table 1 for specific requirements

[0033] Requirements for base surface and skirting table 1

[0034]

[0035] 1.2) Sweep the base of the floor slab clean to a state where there is no dust and the moisture content is not more than 10%.

[0036] 1.3) Meet the operating conditions, that is, the structural engineering acceptance is qualified, the elevation control line (+500mm) is well bombed and the pre-inspection is qualified. Install the baseboard rubber tape and stick it to the wall with an adhesive, stretch it evenly. The pipeline reservation, pre-buried and installation related to the profession has been completed and passed the preliminary in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com