Method for preparing surfactant-directed grown superfine bismuth molybdate nano rods

A surfactant, ultra-fine nanotechnology, applied in nanotechnology, chemical instruments and methods, molybdenum compounds, etc., to achieve the effects of high yield, uniform size, and strong controllability of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

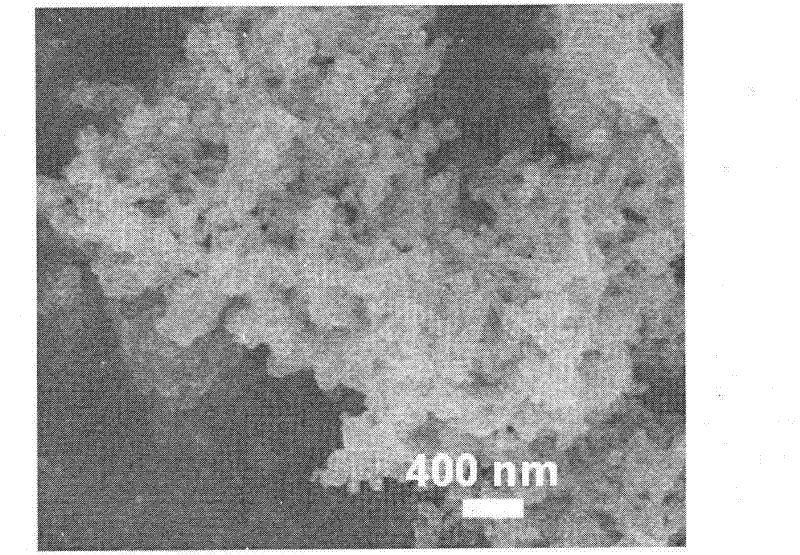

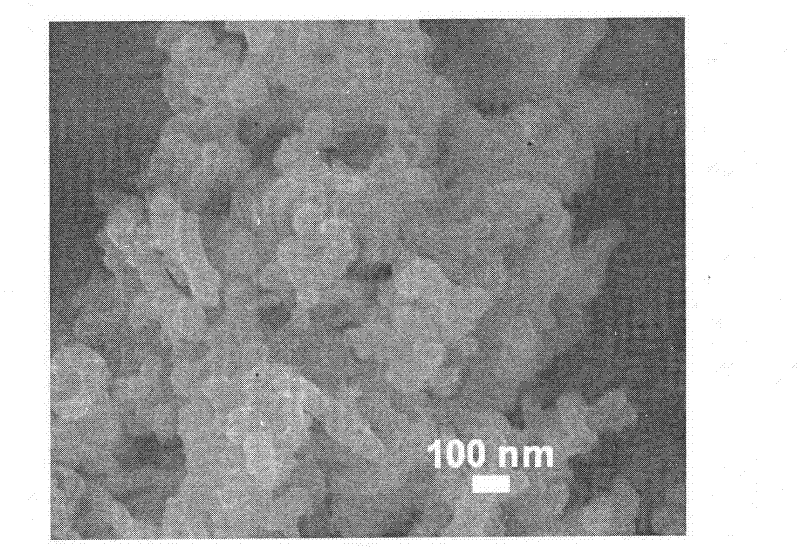

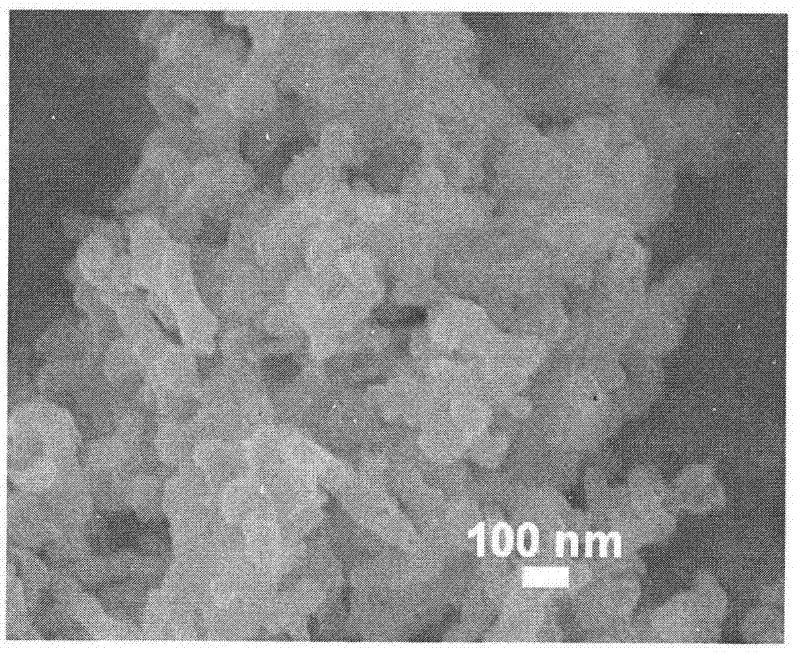

[0018] At room temperature, the configuration of Bi(NO 3 ) 3 The molar concentration of bismuth nitrate solution is 0.2mol / L, then add CTAB in solution and make its molar concentration in solution be 0.02mol / L, fully stir 10 minutes; Weigh (NH 4 ) 6 Mo 7 o 24 4H 2 O ammonium molybdate solid, add distilled water and stir evenly until the ammonium molybdate is completely dissolved to obtain a uniform clear solution, then dropwise added to the bismuth nitrate solution, fully stirred for 8 minutes; the above reaction precursor is poured into a glass circle Bottom flask, and placed in an atmospheric pressure microwave radiation reactor to react for 30 minutes, the product prepared after the reaction is pure-phase bismuth molybdate ultrafine nanorods, and X-ray diffraction analysis shows that its composition is Bi 2 Mo 3 o 12 . The product was detected by scanning electron microscopy (SEM) and showed that ( figure 1 ) whose main body shape is ultrafine nanorods with uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com