Dry sand making process

A production process and process technology, applied in the field of concrete machine-made sand preparation process, can solve the problems of large production line area, single crushing system, and difficulty in popularization and application, and achieve the effects of no dust pollution, wide crushing range, and superior sand type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which should not be construed as a limitation of the present invention;

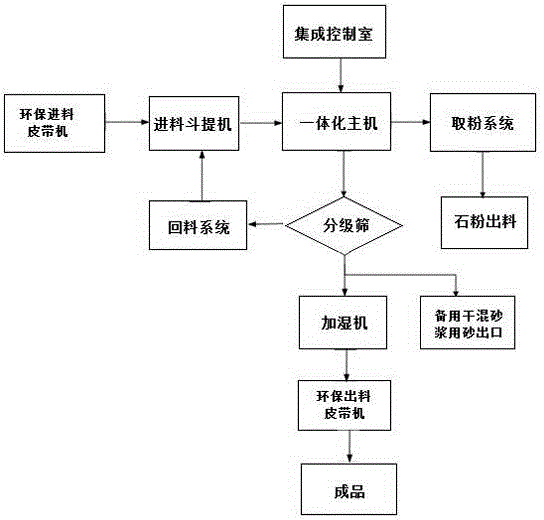

[0026] Such as figure 1 As shown, a dry sand making process, the production process includes the following steps:

[0027] Step 1: crushing treatment;

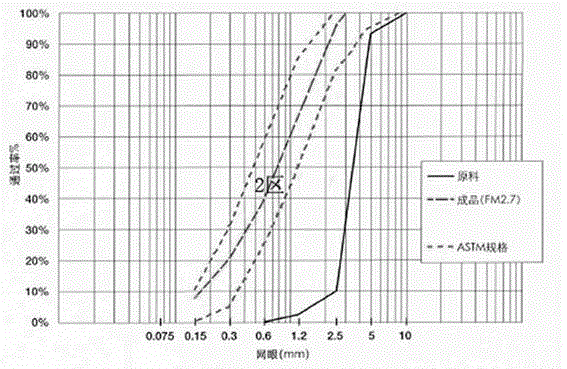

[0028] Firstly, the raw material blocks are transported to the feeding hopper elevator through the belt transmission equipment. The raw materials of the block stones are pebbles, granite, limestone, etc., and the size range of the blocks is 10-20cm. The feeding hopper elevator is connected to the integrated crushing host , transport the block stones to the integrated crushing host through the feeding bucket elevator. The integrated crushing host is equipped with strong stirring, crushing equipment and dust removal equipment. The dust removal equipment is a negative pressure powder removal device, and the crushing equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com