Biodegradable polyester with high gas barrier property and preparation method and application thereof

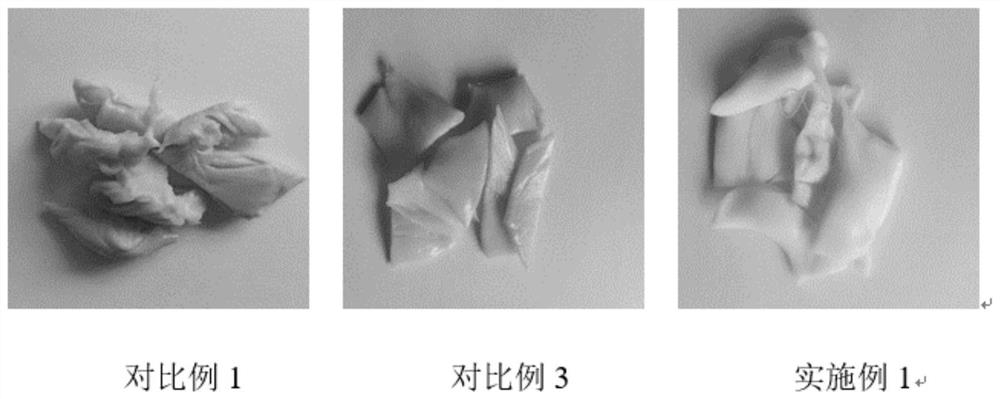

A biodegradable polyester, gas barrier technology, used in biological packaging, polyester coatings, flexible coverings, etc., can solve the side reaction of biodegradable polyester discoloration, the product turns red or orange, and increase production costs, etc. problems, to achieve the effect of industrialized production and application, high-performance color, process energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

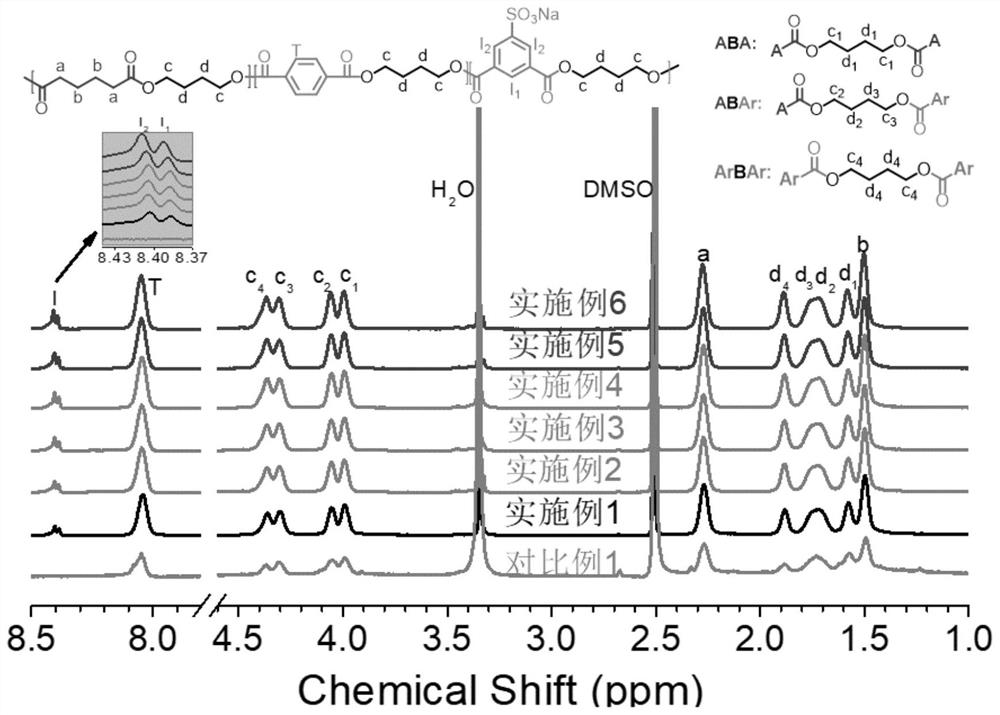

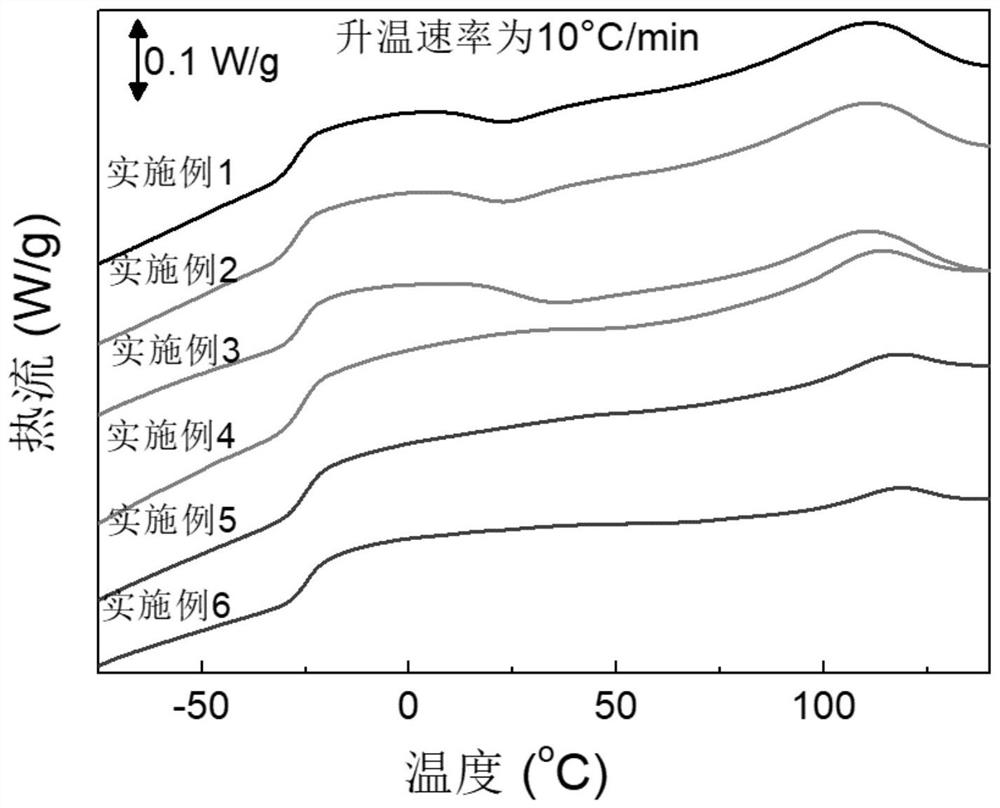

Embodiment 1

[0054] (1) Add 28.94g (0.198mol) of adipic acid, 26.91g (0.162mol) of terephthalic acid and 64.89g (0.72mol) of 1,4-butanediol in a 250mL four-necked flask, wherein the acid-alcohol ratio is 1:2, under the protection of nitrogen atmosphere and mechanical stirring, when the esterification temperature reaches 180°C, add 0.12g (0.21wt%, based on the amount of dibasic acid) catalyst n-tetrabutyl titanate, and the system is at 180°C The reaction was carried out at low temperature for about 2 hours, and the temperature was raised to 215°C to react until the distillate water no longer increased, and the system was clear and transparent, and prepolymer 1 was obtained.

[0055] Add 9.73g (0.108mol) 1,4-butanediol and 7.40g (0.0250mol) sodium dimethyl isophthalate-5-sulfonate to a 25mL three-necked flask (dimethyl isophthalate-5-sulfonate Sodium acid sodium accounts for 6.5mol% of the sum of the moles of all dibasic acids and dibasic acid diesters), the ester-alcohol ratio is 1: 4.33, u...

Embodiment 2

[0059] (1) Add 28.94g (0.198mol) of adipic acid, 26.91g (0.162mol) of terephthalic acid and 64.89g (0.72mol) of 1,4-butanediol in a 250mL four-necked flask, wherein the acid-alcohol ratio is 1:2, in the case of nitrogen atmosphere protection and mechanical stirring, when the esterification temperature reaches 180°C, add 0.12g (0.21wt%, based on the amount of dibasic acid) catalyst n-tetrabutyl titanate, the system is at 180°C The reaction was carried out at low temperature for about 2 hours, and the temperature was raised to 215°C to react until the distillate water no longer increased, and the system was clear and transparent, and prepolymer 1 was obtained.

[0060] Add 11.26g (0.125mol) 1,4-butanediol and 8.55g (0.0289mol) sodium dimethyl isophthalate-5-sulfonate to a 25mL three-necked flask (dimethyl isophthalate-5-sulfonate Sodium acid sodium accounts for 7.4mol% of the sum of the moles of all dibasic acids and dibasic acid diesters), wherein the ester-alcohol ratio is 1: ...

Embodiment 3

[0064] (1) Add 28.94g (0.198mol) of adipic acid, 26.91g (0.162mol) of terephthalic acid and 64.89g (0.72mol) of 1,4-butanediol in a 250mL four-necked flask, wherein the acid-alcohol ratio is 1:2, under the protection of nitrogen atmosphere and mechanical stirring, when the esterification temperature reaches 180°C, add 0.12g (0.21wt%, based on the amount of dibasic acid) catalyst n-tetrabutyl titanate, and the system is at 180°C The reaction was carried out at low temperature for about 2 hours, and the temperature was raised to 215°C to react until the distillate water no longer increased, and the system was clear and transparent, and prepolymer 1 was obtained.

[0065] Add 12.80g (0.142mol) 1,4-butanediol and 9.73g (0.0328mol) dimethyl isophthalate-5-sodium sulfonate to a 25mL three-necked flask (dimethyl isophthalate-5-sulfone Sodium acid sodium accounts for 8.4mol% of the sum of the moles of all dibasic acids and dibasic acid diesters), wherein the acid-alcohol ratio is 1: 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com