Full-automatic stirring/cleaning integrated device for coating jar

An integrated device and fully automatic technology, which is applied to mixers with rotating stirring devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve the irritating and harmful nature of cleaning solvents, high labor costs, operating costs and operational difficulties, Increased electricity costs and other issues, to achieve the effect of low price, ensure safety, and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is capable of tracking the current liquid level, rotating and stirring in a forward-reverse switching mode and a reciprocating lifting mode, and is an automatic stirring function device that operates in different rotation speed modes according to different working conditions and intensity of stirring and mixing requirements; at the same time It is also an automatic cleaning function device that tracks the highest liquid level memory value and scrapes the inner wall of the cylinder container with forward-reverse rotation switching and reciprocating lifting.

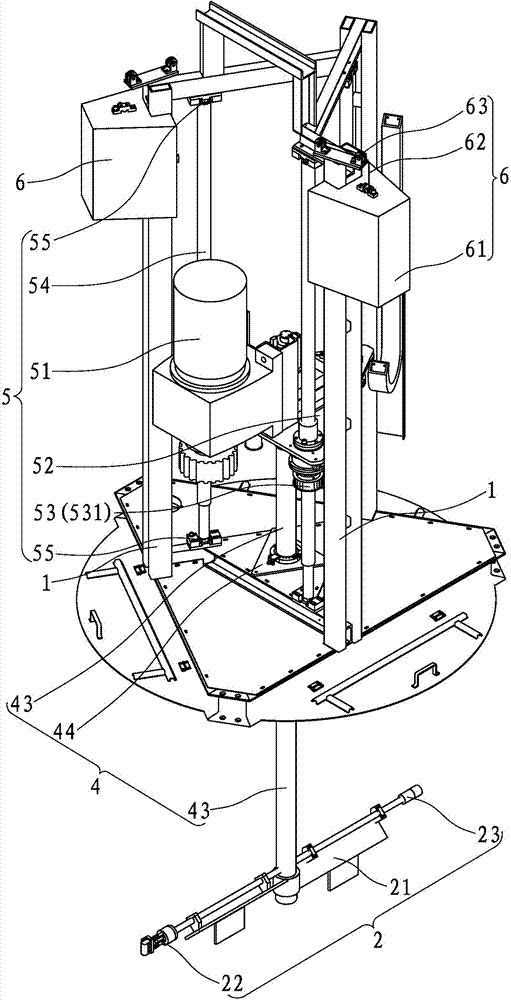

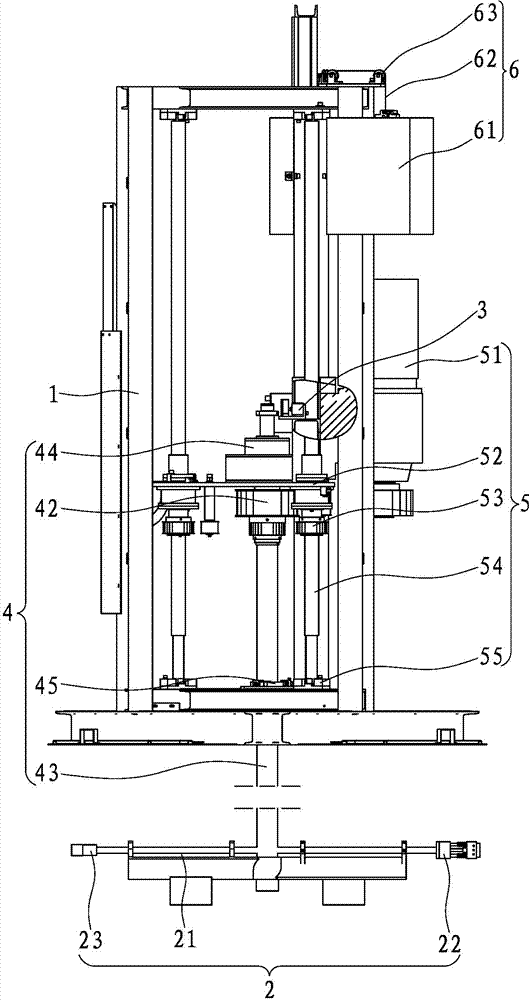

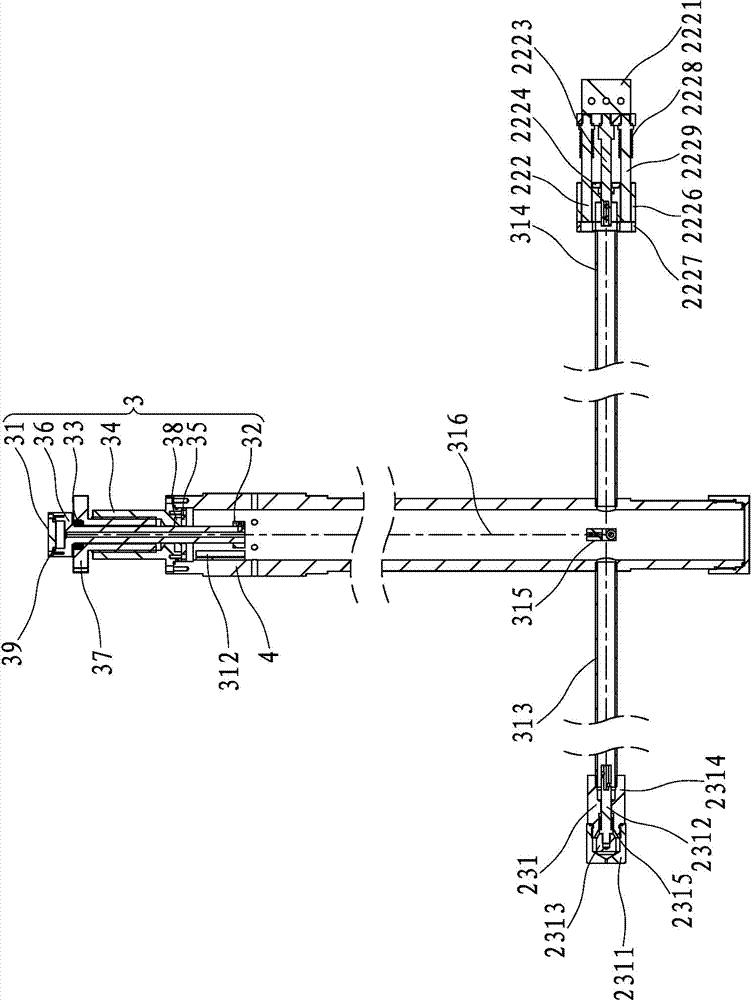

[0032] like figure 1 , figure 2 As shown, the present invention is a fully automatic stirring / cleaning integrated device for paint vats, including a frame 1, a stirring / cleaning rotating mechanism 2, an actuating mechanism 3 for switching between stirring / cleaning operation modes, a spindle rotating mechanism 4, a lifting Mechanism 5, counterweight mechanism 6 and automatic control system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com