Latent curing system used for moulding prepregs at medium or low temperature and method for preparing latent curing system

A latent curing agent and prepreg technology, applied in the field of composite materials, can solve the problems of complex process, serious energy consumption, and difficulty in industrialized production of modified latent curing agents and room temperature reactive curing agents. The effect of industrialized production, less human injury and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 500g of dicyandiamide and 400g of aliphatic amine and place them in a reaction kettle, stir vigorously until the dicyandiamide and aliphatic amine are mixed evenly, add 100g of phenyl glycidyl ether and 10g of 2-methylimidazole, and react at 60°C for 6h , After cooling the product, a white pasty liquid is obtained, which is a latent curing system for medium and low temperature molding prepregs.

[0022] Weigh 50g of the above-prepared latent curing system for low-temperature molding prepreg and 500g of epoxy resin E-44, stir them evenly, pour them into the spline mold, and cure at 80°C for 8h to prepare the cast body spline. The properties of the latent curing system for medium and low temperature molding prepregs are shown in Table 1, and the properties of the cast body are shown in Table 2.

Embodiment 2

[0024] Weigh 800g of modified dicyandiamide and 600g of alicyclic amine and place them in a reaction kettle, stir vigorously until the modified dicyandiamide and alicyclic amine are mixed evenly, then add 300g of bisphenol A glycidyl ether and 50g of 2-ethyl - 4-Methylimidazole, react at 80°C for 4 hours, and cool the product to obtain a white paste liquid, which is a latent curing system for medium and low temperature molding prepregs.

[0025] Weigh 62.5g of the above-prepared latent curing system for low-temperature molding prepreg and 500g of epoxy resin E-44, stir them evenly, pour them into the spline mold, and cure at 90°C for 6h to prepare the cast body spline. The properties of the latent curing system for medium and low temperature molding prepregs are shown in Table 1, and the properties of the cast body are shown in Table 2.

Embodiment 3

[0027] Weigh 1000g of urea derivatives and 800g of polyetheramine respectively and put them in the reaction kettle, stir vigorously until the urea derivatives and polyetheramine are mixed evenly, then add 500g of bisphenol F glycidyl ether and 100g of 1-benzyl-2 - Ethylimidazole, react at 100°C for 2 hours, and the product is cooled to obtain a white paste liquid, which is a latent curing system for medium and low temperature molding prepregs.

[0028] Weigh 75g of the above-prepared latent curing system for low-temperature molding prepreg and 500g of epoxy resin E-44, stir them evenly, pour them into a spline mold, and cure at 100°C for 4 hours to prepare a cast body spline. The properties of the latent curing system for medium and low temperature molding prepregs are shown in Table 1, and the properties of the cast body are shown in Table 2.

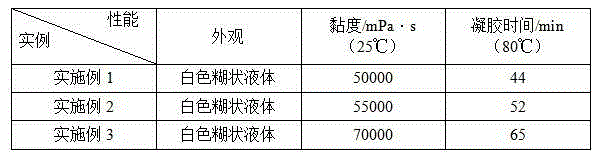

[0029] Table 1 Properties of latent curing system for medium and low temperature molding prepregs

[0030]

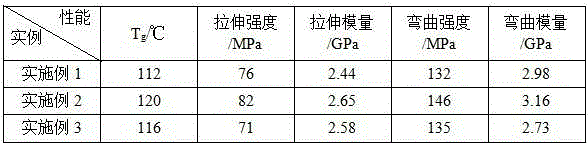

[0031] Table 2 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com