Glue dispensing device for filter production processing

A dispensing device and filter technology, applied in the direction of spraying device, device for coating liquid on the surface, mixer with rotating stirring device, etc., can solve problems such as curing, affecting dispensing effect, and rapid temperature drop, and achieve The surface is clean, convenient for subsequent cleaning, and the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

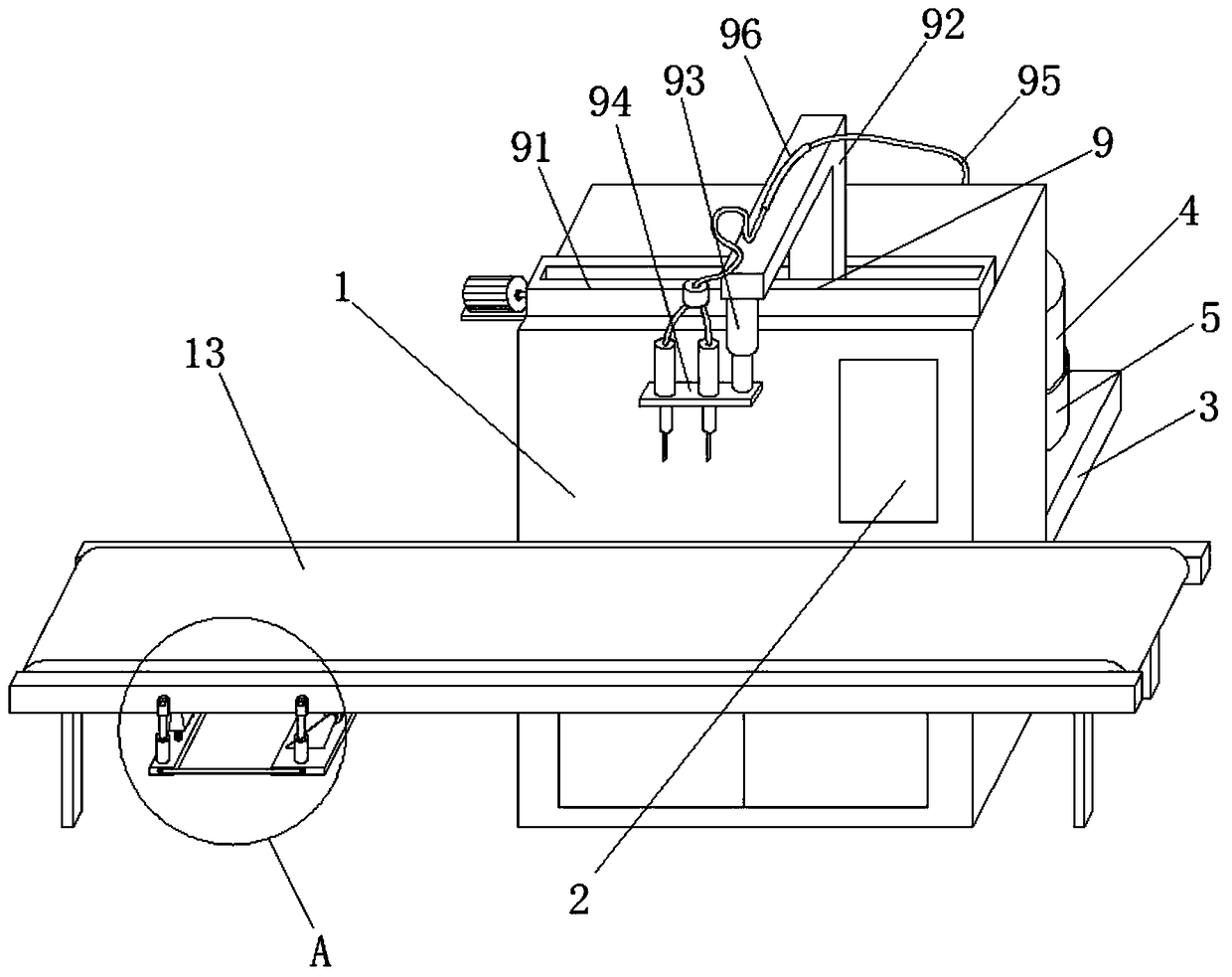

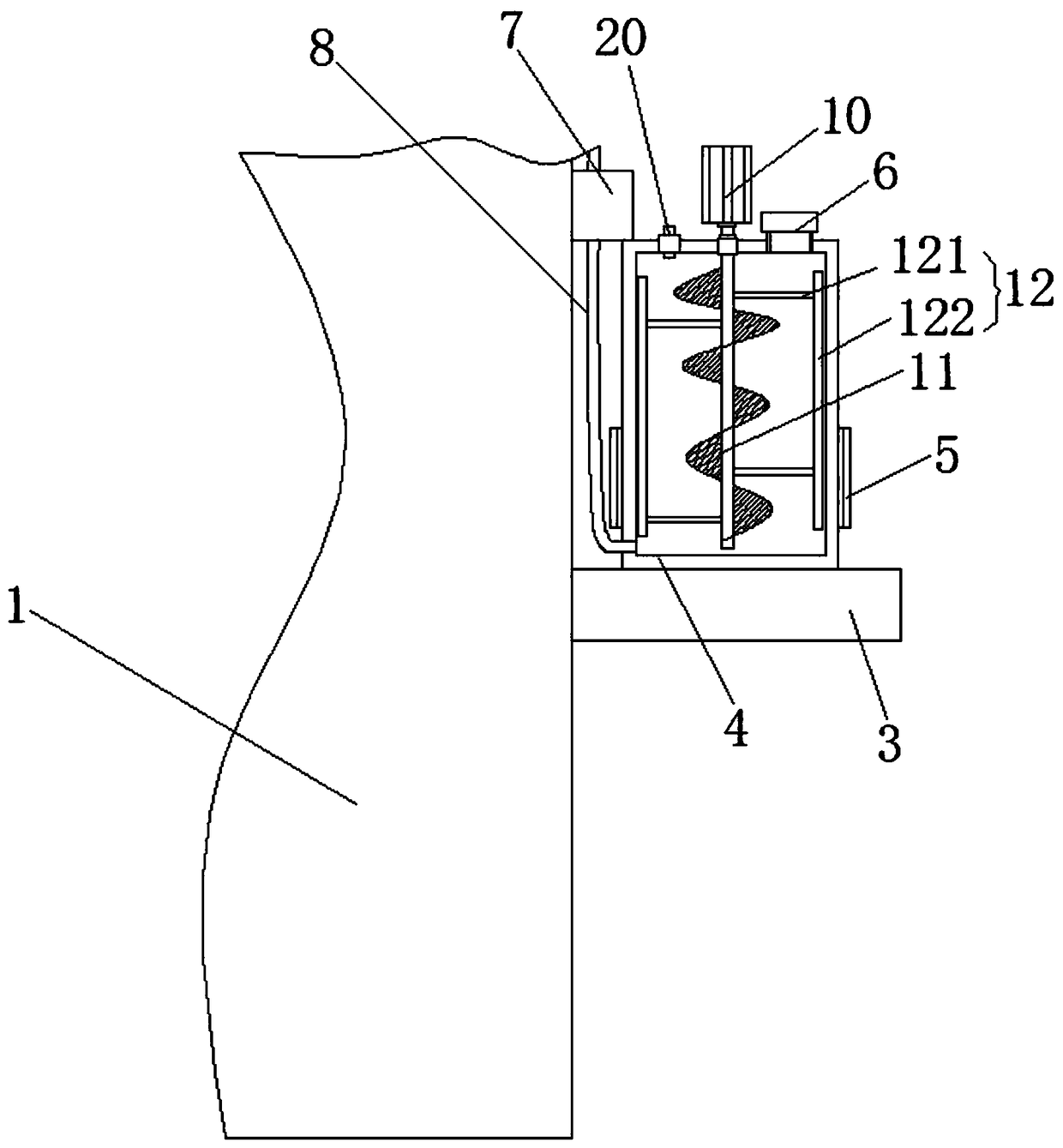

[0024] See Figure 1-4 This embodiment provides a glue dispensing device for filter production and processing, including a frame 1, a control panel 2 is provided on the front of the frame 1, and a support plate 3 is fixedly connected to one side of the frame 1, and the support plate 3 The top of the glue tank 4 is fixedly installed, the surface of the glue tank 4 is sleeved with a heating belt 5, the top of the glue tank 4 is connected with a glue injection pipe 6, and one side of the glue tank 4 is connected with a glue pump 7, preferably a glue pump 7. The model is QBK-40LF46. The top of the frame 1 is equipped with a glue assembly 9 which is connected to the glue pump 7. The top of the glue tank 4 is fixedly installed with a first motor 10, and the output shaft of the first motor 10 is fixedly connected There are mixing blades 11, which are located inside the glue tank 4. Both sides of the mixing blades 11 are fixedly connected with scraper components 12, and the other side ...

Embodiment 2

[0027] See Figure 1-4 , A further improvement is made on the basis of embodiment 1: the lower end of one side of the glue tank 4 is connected with a rubber outlet pipe 8, the glue pump 7 is connected with the glue tank 4 through the rubber outlet pipe 8, and the rubber outlet pipe 8 plays the role of connecting the glue pump 7. , And the glue outlet tube 8 is located at the lower end of one side, which facilitates the outflow of glue, makes the use of glue more thorough, and reduces the residual amount of glue inside the glue tank 4.

[0028] Among them, the dispensing assembly 9 includes a sliding device 91, the top of the sliding device 91 is fixedly connected with an L-shaped bracket 92, and a hydraulic rod 93 is arranged under the L-shaped bracket 92. The preferred model of the hydraulic rod 93 is SFY-001, The bottom of the hydraulic rod 93 is fixedly connected with a glue head 94. The top of the glue head 94 is connected with a pipe 95, which communicates with the glue pump...

Embodiment 3

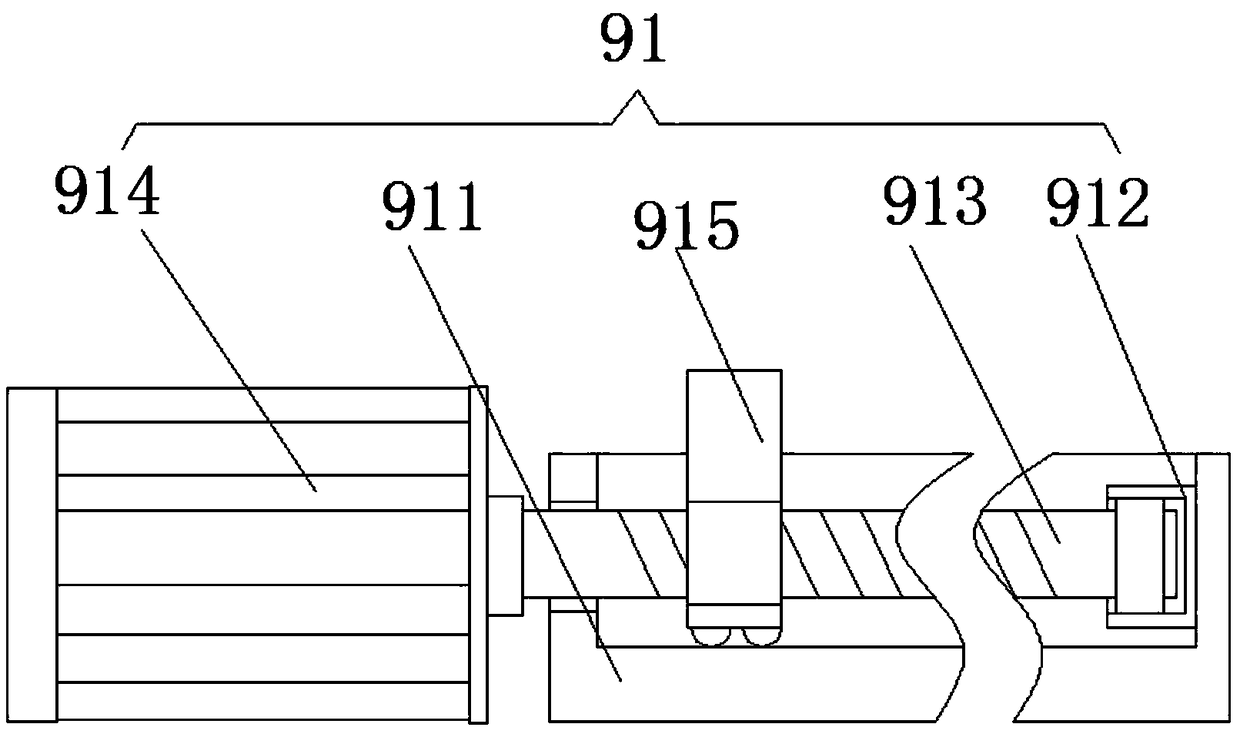

[0030] See Figure 1-4 , On the basis of embodiment 1, a further improvement is made: the sliding device 91 includes a sliding rail 911, the inner wall of the sliding rail 911 is fixedly connected with a rotating seat 912, the inner wall of the rotating seat 912 is rotatably connected with a screw rod 913, the rotating seat 912 A bearing is arranged inside, and the bearing is fixedly connected to the screw rod 913. A second motor 914 is fixedly installed on one side of the sliding rail 911. One end of the screw rod 913 penetrates the sliding rail 911 and is fixedly connected to the output shaft of the second motor 914. The screw rod The surface of the 913 is threadedly connected with a movable sleeve 915, and the movable sleeve 915 is fixedly connected with the L-shaped bracket 92. When the dispensing head 94 needs to move in a horizontal direction, the second motor 914 drives the screw rod 913 to rotate to make the movable sleeve 915 move. In this way, the L-shaped bracket 92 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com