Environment-friendly anti-oxidation imitated gold stamping mucilage and preparing method thereof

An anti-oxidation and environment-friendly technology, which is applied in dyeing, textiles and papermaking, etc., can solve the problems that mucilage is easy to lose its aesthetic effect, metal powder has poor anti-oxidation performance, and fabrics are difficult to reuse. It is not easy to achieve aesthetics. The effect that it is not easy to change color or blacken, and is not easy to be oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

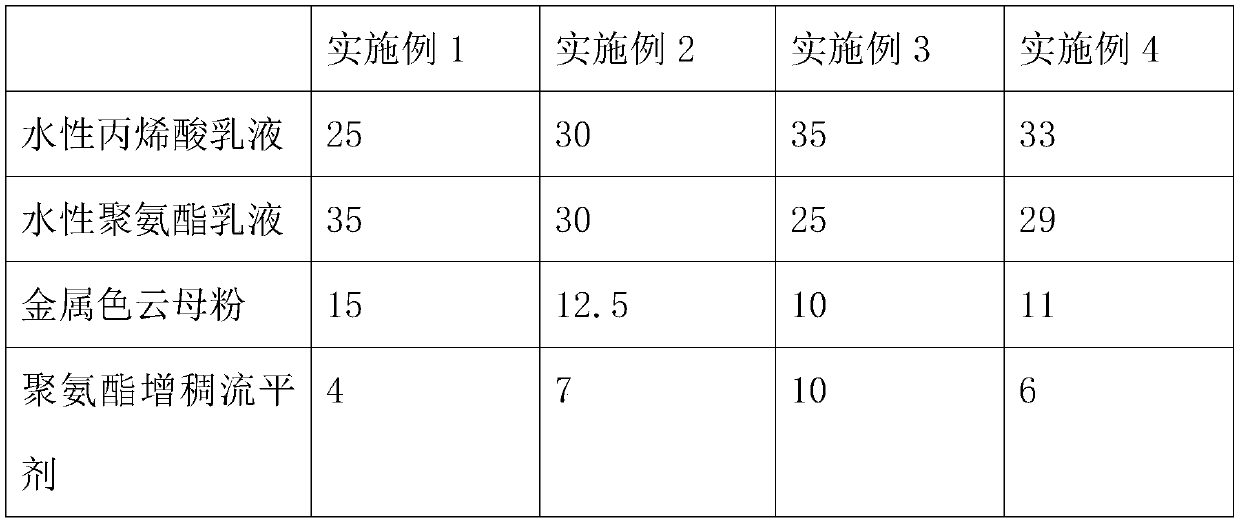

[0087] An environment-friendly anti-oxidation imitation ironing metal glue, the components and contents of raw materials are shown in Table 1, and the content unit of each component in Table 1 is kg.

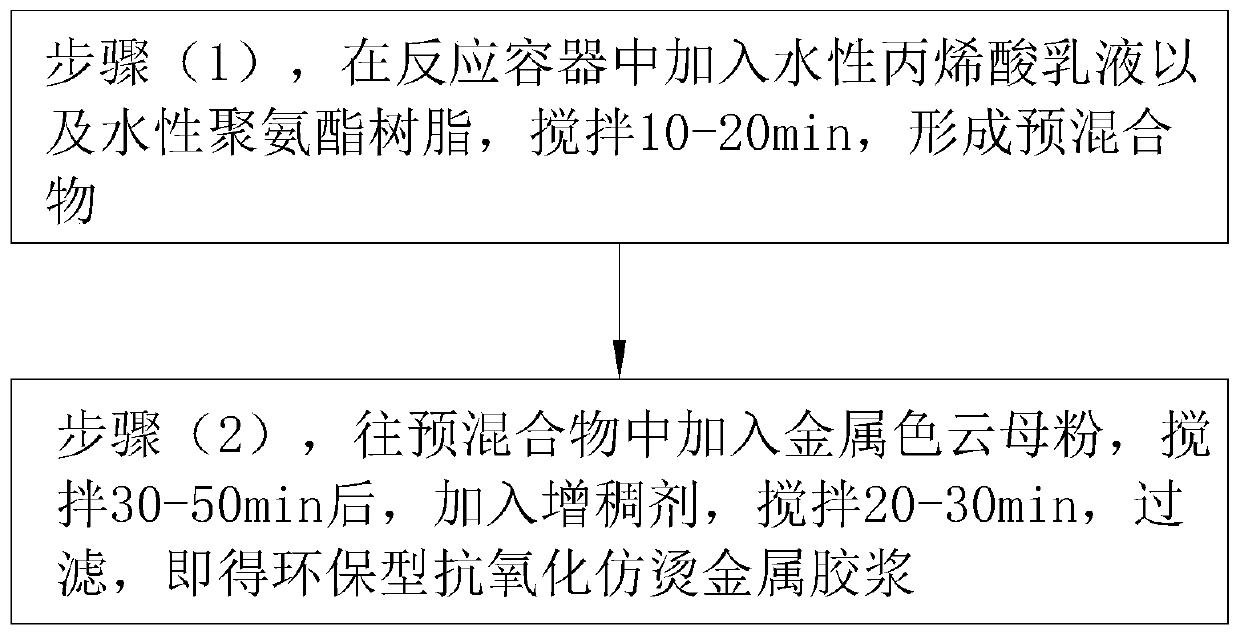

[0088] refer to figure 1 , is the preparation method of a kind of environment-friendly anti-oxidation imitation ironing metal mucilage disclosed by the present invention, comprises the following steps:

[0089] Step (1), cleaning the dispersion tank, adding water-based acrylic emulsion and water-based polyurethane resin into the dispersion tank, stirring at a speed of 1500r / min, stirring for 10min, mixing and dispersing evenly, and forming a premix.

[0090] In step (2), add metallic mica powder to the pre-mixture while stirring, stir and disperse for 30 minutes, then add thickener, stir and disperse for 20 minutes, and filter with 180 mesh gauze to obtain an environmentally friendly anti-oxidation imitation hot metal glue pulp.

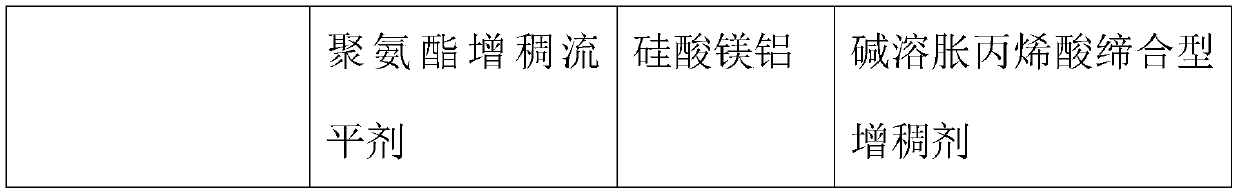

[0091] In this embodiment, the thickener is po...

Embodiment 2

[0093] The difference with embodiment 1 is:

[0094] The composition and content of raw materials are as shown in Table 1;

[0095] The stirring time in step (1) is 15min;

[0096] After adding the metallic mica powder in step (2), stir for 40 minutes; after adding the thickener, stir for 25 minutes; the filtered mesh is 190 mesh.

[0097] In this embodiment, the metallic mica powder is silver mica powder.

Embodiment 3

[0099] The difference with embodiment 1 is:

[0100] The composition and content of raw materials are as shown in Table 1;

[0101] The stirring time in step (1) is 20min;

[0102] After adding the metallic mica powder in step (2), stir for 50 minutes; after adding the thickener, stir for 30 minutes; the filtered mesh is 200 mesh.

[0103] In this embodiment, the metallic mica powder is silver mica powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com