Water-based ink dedicated for gravure surface printing of plastic film, and plastic film

A technology of plastic film and water-based ink, applied in the field of special water-based ink and plastic film for gravure printing on plastic film, can solve problems such as the gap in printing suitability, achieve strong migration resistance, improve working environment, and high color saturation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

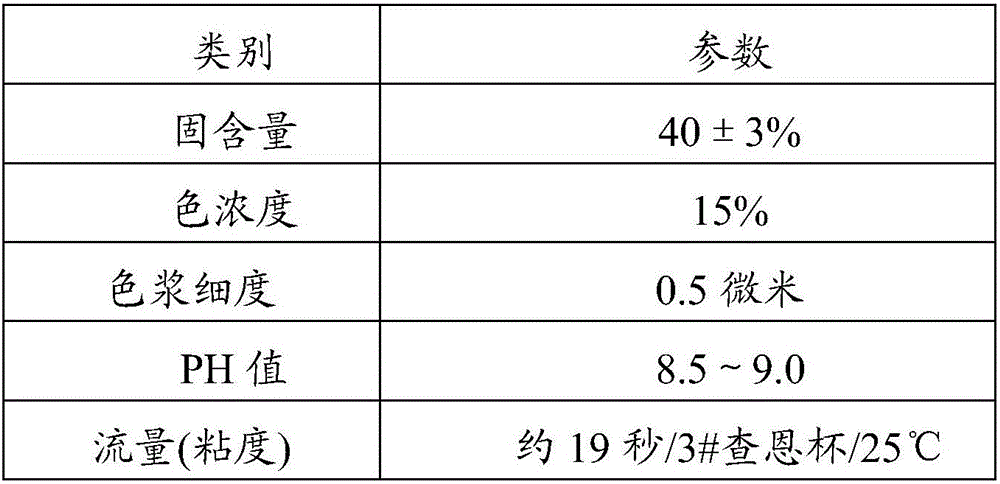

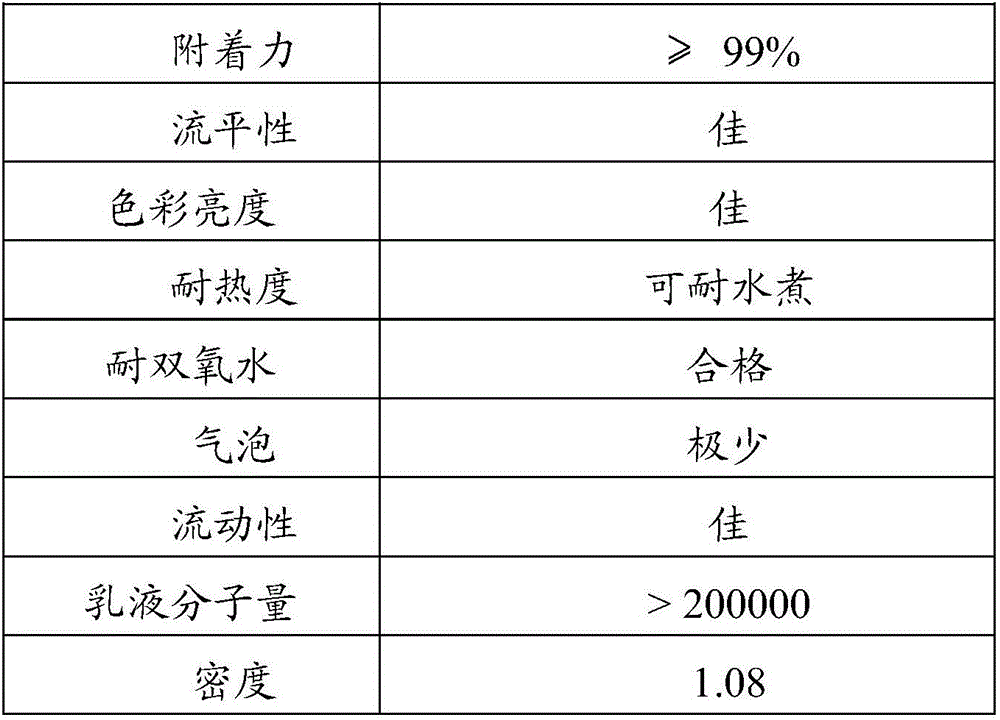

[0021] A special water-based ink for plastic film gravure surface printing, which is prepared from the following raw materials:

[0022] 30 parts of polycarbonate emulsion; 15 parts of pigment; 20 parts of propanol; 2 parts of additive; 1 part of anti-wear agent; 2 parts of ammonia water; 50 parts of deionized water.

[0023] The preparation method of the above-mentioned water-based ink comprises the following steps: mixing polycarbonate emulsion; pigment; propanol; auxiliary agent; Grind to get water-based ink.

Embodiment 2

[0025] A special water-based ink for plastic film gravure surface printing, which is prepared from the following raw materials:

[0026] 30 parts of polycarbonate emulsion; 20 parts of pigment; 30 parts of propanol; 5 parts of auxiliary agent; 2 parts of anti-wear agent; 3 parts of ammonia water; 50 parts of deionized water. The additives include anti-settling agents and antistatic agents. The anti-settling agent is a polyamide wax anti-settling agent, and its mass content is 0.5% of the total amount of water-based ink. The antistatic agent is DENON3342 anionic antistatic agent, and the mass content is 2% of the total amount of water-based ink. The auxiliaries also include pH regulators, preservatives and antifungal agents. The pH regulator is potassium dihydrogen phosphate. The antiseptic can choose sodium benzoate, and the fungicide can choose Proxel CRL.

[0027] The auxiliary agent also includes a defoamer, because the present invention adds a defoamer, which can effec...

Embodiment 3

[0030] A special water-based ink for plastic film gravure surface printing, which is prepared from the following raw materials:

[0031] 30 parts of polycarbonate emulsion; 17 parts of pigment; 25 parts of propanol; 3 parts of auxiliary agent; 2 parts of anti-wear agent; 3 parts of ammonia water; 50 parts of deionized water. The additives include anti-settling agents. The anti-settling agent is selected from P200X polyamide wax anti-settling agent, and the mass content is 2% of the total amount of water-based ink.

[0032] The preparation method of the above-mentioned water-based ink comprises the following steps: mixing and stirring polycarbonate emulsion; pigment; propanol; 2-5 parts of auxiliary agent; anti-wear agent; ammonia water; Grind in a sand mill to obtain water-based ink.

[0033] The above-mentioned special water-based ink for gravure surface printing of plastic films may also be mixed with additives such as pH regulators, preservatives, and antifungal agents. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com