Method for extracting rubidium from rubidium-containing ore through ultrasonic strengthening

A technology of ultrasonic strengthening and ore, which is applied in the direction of improving process efficiency, can solve the problems of high energy consumption, long leaching process time, and low leaching rate, and achieve the effect of increasing leaching rate, avoiding long leaching time, and promoting leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

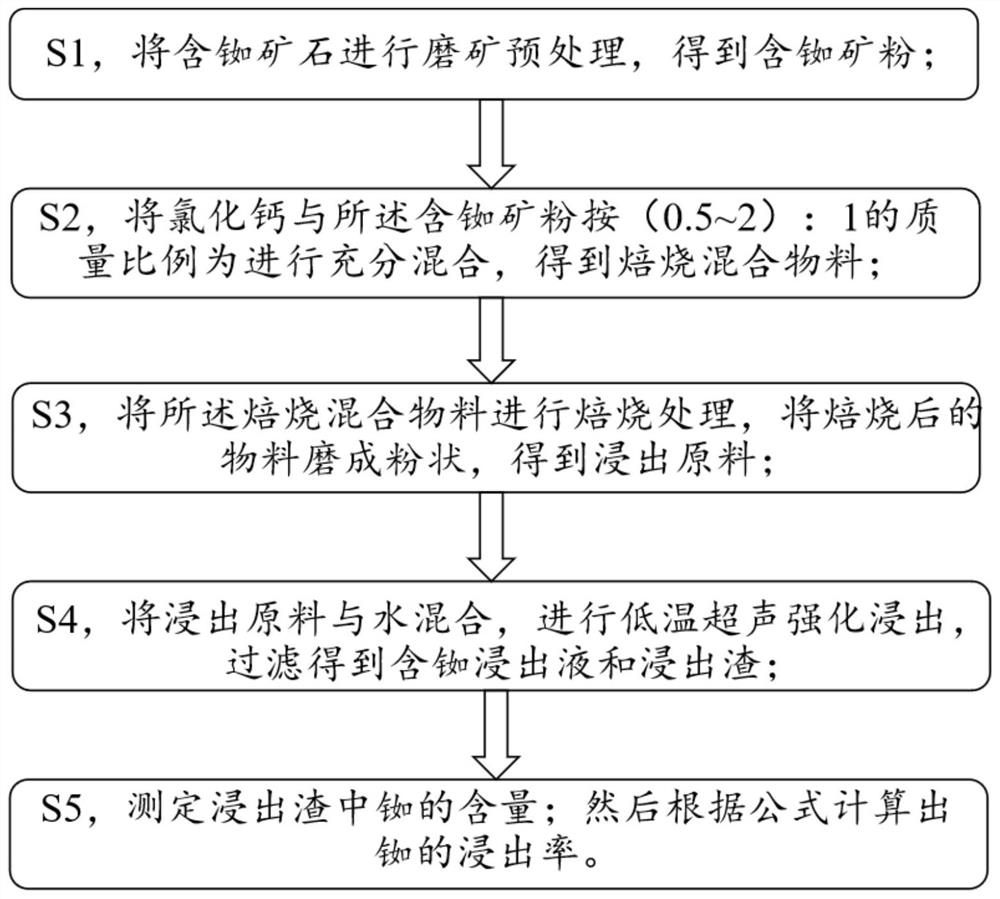

[0047] Embodiment 1 of the present invention provides a method for ultrasonically enhancing the extraction of rubidium from rubidium-containing ores, comprising the following steps:

[0048] Step 1: Put the rubidium-containing ore in the ore grinding machine, and obtain the rubidium-containing ore powder through grinding, as the roasting raw material for the experiment; (in the rubidium-containing ore, the rubidium content is 0.091%)

[0049] Step 2: Fully mix calcium chloride and rubidium-containing ore powder at a mass ratio of 1:1 to obtain a roasted mixture;

[0050] Step 3: Put the roasting mixture into an alumina crucible, and then place it in a muffle furnace for roasting at a temperature of 800°C. The holding time is 25 minutes. After the reaction, take out the crucible and cool it to room temperature. Use the roasted material Grinding machine into powder, used as leaching raw material;

[0051] Step 4: Take 15g of leaching raw materials and put them in a beaker, add ...

Embodiment 2

[0057] Embodiment 2 of the present invention provides a method for ultrasonically enhancing the extraction of rubidium from rubidium-containing ores, comprising the following steps:

[0058] Step 1: Put the rubidium-containing ore in the ore grinding machine, and obtain the rubidium-containing ore powder through grinding, as the roasting raw material for the experiment; (in the rubidium-containing ore, the rubidium content is 0.091%)

[0059] Step 2: Fully mix calcium chloride and rubidium-containing ore powder at a mass ratio of 1:1 to obtain a roasted mixture;

[0060] Step 3: Put the roasting mixture into an alumina crucible, and then place it in a muffle furnace for roasting at a temperature of 800°C. The holding time is 25 minutes. After the reaction, take out the crucible and cool it to room temperature. Use the roasted material Grinding machine into powder, used as leaching raw material;

[0061] Step 4: Take 15g of the leaching raw material and put it in a beaker, add...

Embodiment 3

[0067] Embodiment 3 of the present invention provides a method for ultrasonically enhancing the extraction of rubidium from rubidium-containing ores, comprising the following steps:

[0068] Step 1: Put the rubidium-containing ore in the ore grinding machine, and obtain the rubidium-containing ore powder through grinding, as the roasting raw material for the experiment; (in the rubidium-containing ore, the rubidium content is 0.091%)

[0069] Step 2: Fully mix calcium chloride and rubidium-containing ore powder at a mass ratio of 1:1 to obtain a roasted mixture;

[0070] Step 3: Put the roasting mixture into an alumina crucible, and then place it in a muffle furnace for roasting at a temperature of 800°C. The holding time is 25 minutes. After the reaction, take out the crucible and cool it to room temperature. Use the roasted material Grinding machine into powder, used as leaching raw material;

[0071] Step 4: Take 15g of leaching material and put it in a beaker, add deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com