Method for extracting and separating proanthocyanidins from lycium ruthenicum murr

A technology of black fruit wolfberry and proanthocyanidins, applied in the field of health food and medicine, plant active ingredient extraction, and food, can solve the problems of not meeting quality requirements, low content of oligomers and polyphenols, etc., and achieve low cost and high osmotic pressure , the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

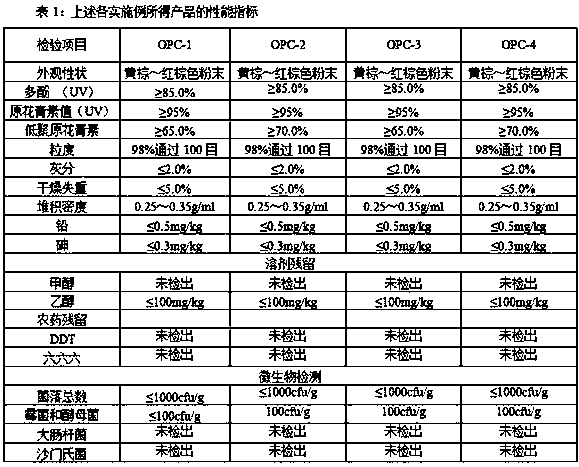

Examples

Embodiment 1

[0027] 1) Take black wolfberry, crush it, and pass through a 40-mesh sieve; add 1.0 kg of black wolfberry powder into a multifunctional extraction tank, add 12L of 60% ethanol solution, add 10 g of citric acid and 15 g of malic acid, and turn on the high-speed shear Cut off the machine, set the speed at 10000rpm; start stirring, set the speed at 120rpm; start timing when the temperature rises to 60°C, and extract for 0.5 h; filter the extract, then add 10L of 60% ethanol to extract under the same conditions, and combine 2 secondary extract;

[0028] 2) Concentrate the above extract under reduced pressure and vacuum until there is no alcohol smell: the temperature is 50°C, and the pressure is 0.07MPa;

[0029] 3) Pump the concentrated extract obtained in step 2) into the pre-treated macroporous adsorption resin mixed resin simulation bed (two resin columns connected in series, LSA-10: XDA-6: D101=2: 3:5 , the ratio of diameter to height is 1:12), the sample loading flow rate i...

Embodiment 2

[0033]1) Take 25 kg of black wolfberry powder that has been crushed through a 40-mesh sieve, put it in a multi-functional extraction tank, add 15 times the amount of 70% ethanol, turn on the high-speed shearing machine, set the speed at 10,000 RPM, and start stirring at the same time, Set the speed at 120RPM. When the temperature rises to 60°C, start timing. Extract for 1 h, let it stand for 2 h, and drain the extract from the drain port on the side of the extraction tank;

[0034] 2) Concentrate the above extract with a double-effect concentrator to recover alcohol until there is no alcohol smell, at a temperature of 50°C and a pressure of 0.075MPa;

[0035] 3) Pump the concentrated extract obtained in step 2) into the pre-treated macroporous adsorption resin mixed resin simulation bed (two resin columns connected in series, LSA-10: XDA-6: D101=2: 3:5 , the ratio of diameter to height is 1:12), the sample loading flow rate is 1.5 BV / HR, after the sample is loaded, it is fir...

Embodiment 3

[0039] 1) Take 1 kg of black wolfberry powder crushed through a 40-mesh sieve, put it in a multi-functional extraction tank, add 12 times the amount of 60% ethanol for the first time, and add 10 times the amount of 60% ethanol for the second time. Turn on the high-speed shearing machine, set the rotating speed to be 10000 RPM, and simultaneously turn on the stirring, and set the rotating speed to be 120 RPM. When the temperature rises to 60°C, start timing. Extract for 0.5 h, extract twice; stand for 2 h, drain the extract from the drain port on the side of the extraction tank, and combine the extract;

[0040] 2) Use a vacuum rotary evaporator to recover alcohol from the above extract until there is no alcohol smell, at a temperature of 50°C and a pressure of 0.075MPa;

[0041] 3) Pump the concentrated extract obtained in step 2) into the pre-treated macroporous adsorption resin mixed resin simulation bed (two resin columns connected in series, LSA-10: XDA-6: D101=2: 3:5 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com