Soaking solution for removing rusty yellow spots of white cobblestones, preparation method thereof, and method for removing rusty yellow spots of white cobblestones

A cobblestone and rust-yellow spot technology, applied in the field of white pebble treatment, can solve the problems of corroded pebbles, equipment corrosion, easy formation of acid mist, etc., and achieve the effect of increasing the leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

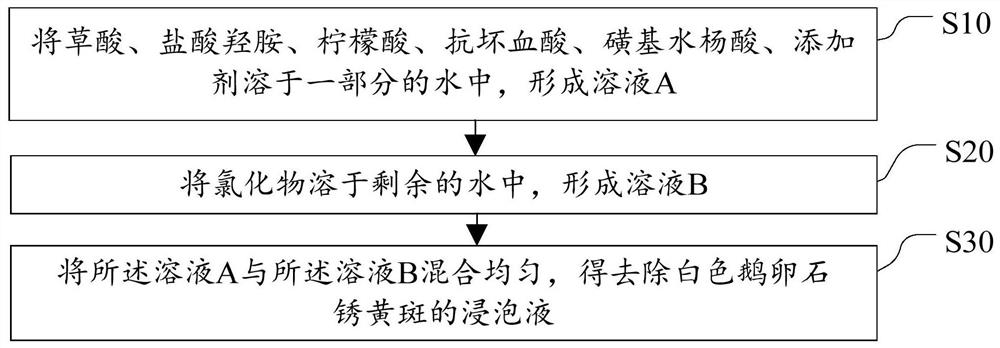

[0046] see figure 1 , the present invention further proposes a method for preparing the soaking solution for removing white cobblestone rust and yellow spots as described above, comprising the following steps:

[0047] S10, dissolving oxalic acid, hydroxylamine hydrochloride, citric acid, ascorbic acid, sulfosalicylic acid, and additives in a part of water to form a solution A;

[0048] S20, dissolving the chloride in the remaining water to form a solution B;

[0049] S30, uniformly mixing the solution A and the solution B to obtain a soaking solution for removing rust and yellow spots of white pebbles.

[0050] The preparation method of the above-mentioned soaking solution for removing white cobblestone rust and yellow spots of the present invention is simple and easy to obtain, and has all the beneficial effects of the above-mentioned soaking solution for white cobblestone rust and yellow spots, and will not be repeated here.

[0051] The present invention further proposes...

Embodiment 1

[0059] (1) Weigh 2g of oxalic acid, 1.2g of hydroxylamine hydrochloride, 1.8g of citric acid, 1.5g of ascorbic acid, 0.5g of sulfosalicylic acid, 1g of hydroxyethylidene diphosphonic acid, 0.4g of low-foam penetrant SF, and dissolve them in 70g of Solution A was formed in water, and then 0.6g of ammonium chloride was weighed and dissolved in 21g of water to form solution B, solution B was slowly added to solution A, and stirred while adding, to obtain a soaking solution.

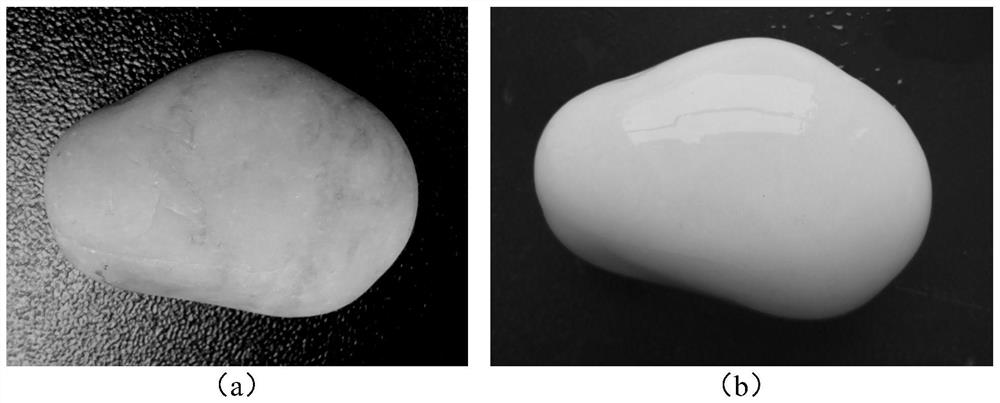

[0060] (2) Clean the rusty white pebbles with water, put them into the soaking solution, take them out after soaking for 5 days at a temperature of 25° C., rinse them with clean water, and complete the removal of the rusty yellow spots on the white pebbles.

[0061] figure 2 Be the picture of cobblestone before and after the rusty yellow spot is removed for the present embodiment, wherein, (a) is the picture of cobblestone before soaking, (b) is the picture of cobblestone after soaking 5 days with present e...

Embodiment 2

[0063] (1) Weigh 1g of oxalic acid, 1.8g of hydroxylamine hydrochloride, 2g of citric acid, 2g of ascorbic acid, 2g of sulfosalicylic acid, 2g of hydroxyethylidene diphosphonic acid, dissolve in 70g of water to form solution A, and then weigh 0.2g of chlorine Dissolve ammonium chloride and 0.1 g of sodium chloride in 18.9 g of water to form solution B, slowly add solution B into solution A, and stir while adding, to obtain a soaking solution.

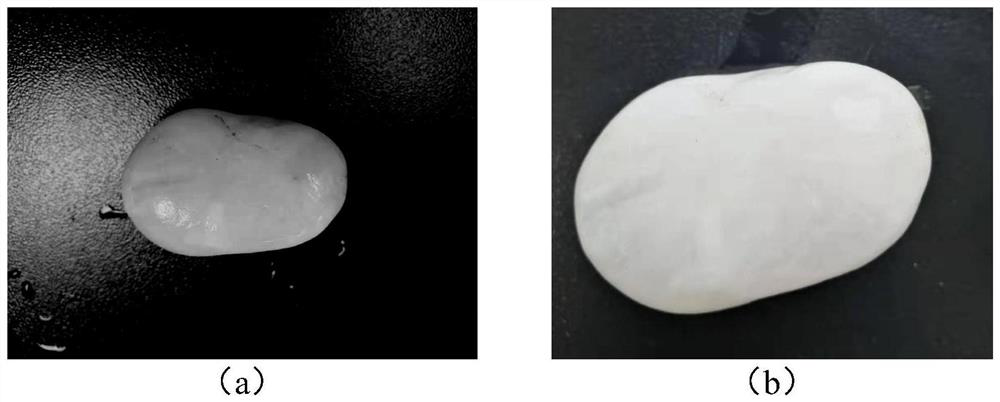

[0064] (2) Clean the rusty white pebbles with water, put them into the soaking solution, take them out after soaking for 6 days at a temperature of 25° C., rinse them with clean water, and complete the removal of the rusty yellow spots on the white pebbles.

[0065] image 3 Be the picture of cobblestone before and after the removal of rusty macula for the present embodiment, wherein, (a) is the picture of cobblestone before immersion, (b) is the picture of cobblestone after soaking 6 days with present embodiment soaking liquid, as can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com