Preparation method of nano-structure WC-Co composite powder

A technology of composite powder and nanostructure, which is applied in the field of nanoscale WC-Co preparation, can solve the problems of limiting the final structure size, coarsening of reaction time particles, etc., to achieve carbide nucleation and grain growth inhibition, and the process is simple and reliable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

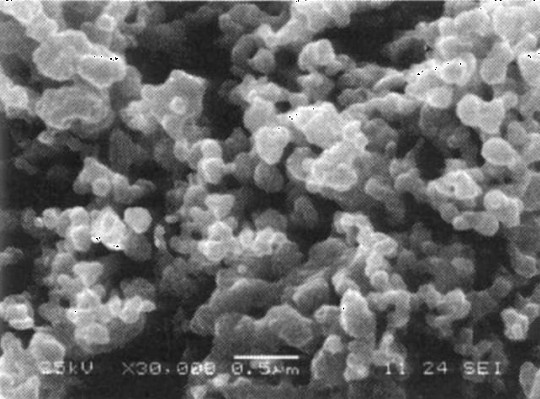

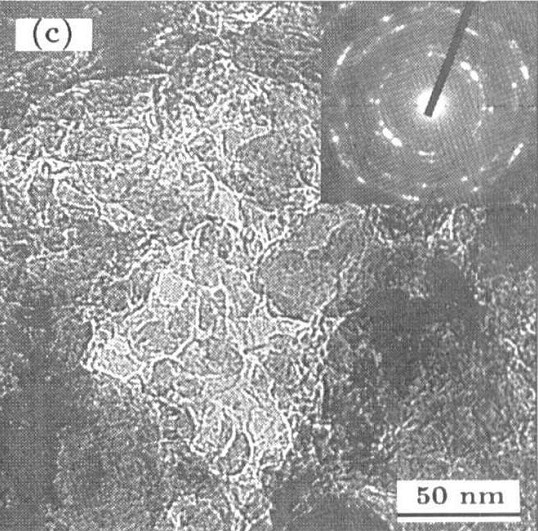

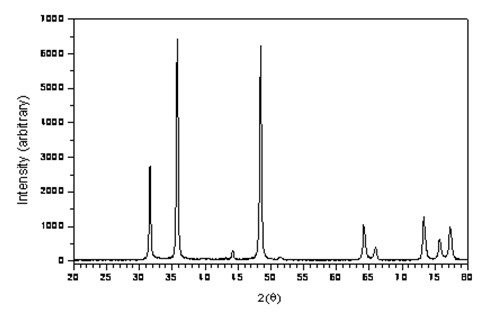

Embodiment 1

[0037] According to WC-10%Co, 0.15%VC, 0.15%Cr 3 C 2 The proportion of metal components (the powder contains 10% metal cobalt, 0.15% VC, 0.15% Cr 3 C 2 , the rest of WC), calculate and weigh metatungstic acid, cobalt nitrate, ammonium metavanadate, ammonium chromate, put them into the bucket, then add an appropriate amount of deionized water and stir, the amount of deionized water is based on the complete dissolution of various metal salts Maximum amount added. Add ultra-fine metallurgical carbon black according to 19% (weight ratio) of tungsten trioxide content. Metallurgical carbon black requires an average particle size of less than 0.1μm and a specific surface area greater than 1800m 2 / g, the sulfur content is less than 10ppm, continue to stir to form a paste, and dry it into a granular powder in a pressure atomization dryer. The air inlet temperature of the dryer is 320-350°C, and the outlet air temperature is 180-200°C. Put the dry composite salt and carbon black m...

Embodiment 2

[0040] According to WC-10%Co, 0.15%VC, 0.15%Cr 3 C 2 The proportion of metal components (the powder contains 10% metal cobalt, 0.15% VC, 0.15% Cr 3 C 2 , the rest of WC), calculate and weigh ammonium metatungstate, cobalt chloride, ammonium metavanadate, chromic acid, put them into a bucket, then add an appropriate amount of deionized water to stir, and the amount of deionized water is completely dissolved with various metal salts for the maximum increase. Add porous carbon, such as activated carbon powder, according to 19% (weight ratio) of the tungsten oxide content, and the activated carbon requires a specific surface area greater than 1800m 2 / g, the carbon content is greater than 99.5%wt, the sulfur content is less than 10ppm, continue to stir to form a paste, and dry it into a granular powder in a pressure atomization dryer. The air inlet temperature of the dryer is 320-350°C, and the outlet air temperature is 180-200°C. Put the dry composite salt and carbon black m...

Embodiment 3

[0043] According to WC-10%Co, 0.15%VC, 0.15%Cr 3 C 2 The proportion of metal components (the powder contains 10% metal cobalt, 0.15% VC, 0.15% Cr 3 C 2 , the rest of WC), calculate and weigh metatungstic acid, cobalt acetate, ammonium metavanadate, ammonium chromate, put them into the bucket, then add an appropriate amount of deionized water and stir, the amount of deionized water is based on the complete dissolution of various metal salts Maximum amount added. Add activated carbon according to 19% (weight ratio) of tungsten oxide content, and the specific surface area of activated carbon is required to be greater than 1800m 2 / g, the carbon content is greater than 99.5%wt, the sulfur content is less than 10ppm, continue to stir to form a paste, and dry it into a granular powder in a pressure atomization dryer. The air inlet temperature of the dryer is 320-350°C, and the outlet air temperature is 180-200°C. Put the dry composite salt and carbon black mixture powder into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com