Method for preparing 2,5-furandicarboxylic acid from biomass compound by electrocatalytic oxidation

A technology of furandicarboxylic acid and compound electricity, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of complex production process, environmental pollution, high catalyst cost, etc., and achieve high conversion rate of raw materials, easy availability of raw materials, and product yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

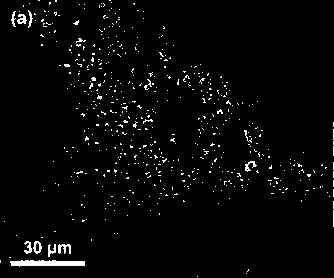

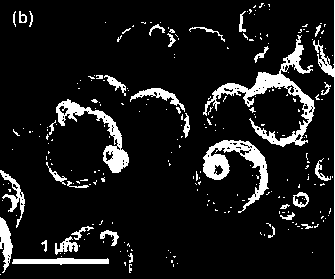

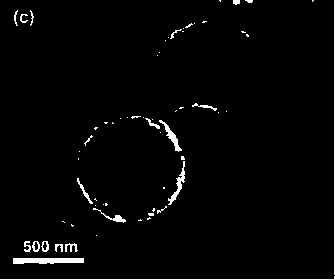

Image

Examples

Embodiment 1

[0051] The preparation of the three-dimensional porous vanadium oxyhydroxide catalyst VOOH / NF supported on the nickel foam is as follows:

[0052] (1) Dissolve 234 mg of ammonium metavanadate in 40 mL of water, add foamed nickel for impregnation, and stir at room temperature for 10 minutes. The mass of the catalyst active component vanadium oxyhydroxide is calculated as 5% of the mass of the carrier foamed nickel. The added partial The amount of substance of ammonium vanadate is 2 mmol;

[0053] (2) Prepare a hydrochloric acid solution with a concentration of 1mol / L, and prepare an 8mol / L aqueous solution of hydrazine hydrate for later use;

[0054] (3) Take 1 mL of the hydrochloric acid solution obtained in step (2) and slowly add it dropwise to the solution obtained in step (1). After stirring at room temperature for 20 minutes, slowly add 2 mL of the reducing agent solution obtained in step (2), and continue stirring at room temperature for 30 minutes;

[0055] (4) Add the...

Embodiment 2

[0059] Supported on copper foam to form a three-dimensional porous vanadium nitride catalyst (VN x / CF) were prepared as follows:

[0060] (1) Dissolve 488 mg of sodium metavanadate in 40 mL of water, add foamed copper for impregnation, and stir at room temperature for 10 minutes. The mass of the catalyst active component vanadium nitride is calculated as 10% of the mass of the carrier foamed copper. The added partial The amount of substance of sodium vanadate is 4 mmol;

[0061] (2) Prepare a sulfuric acid solution with a concentration of 1mol / L, and prepare a 5mol / L sodium borohydride aqueous solution for later use;

[0062] (3) Take 2 mL of the sulfuric acid solution obtained in step (2) and slowly add it dropwise to the solution obtained in step (1). After stirring at room temperature for 20 minutes, slowly add 3 mL of the reducing agent solution obtained in step (2), and continue stirring at room temperature for 30 minutes;

[0063] (4) Add the precursor solution in ste...

Embodiment 3

[0067] Supported on aluminum foam to form a three-dimensional porous vanadium oxide catalyst (VO x / AF) were prepared as follows:

[0068] (1) Dissolve 1.10 g of sodium orthovanadate in 40 mL of water, add foamed aluminum for impregnation, and stir at room temperature for 10 minutes. The mass of vanadium oxide, the active component of the catalyst, is calculated as 15% of the mass of the carrier aluminum foam. The added vanadium The amount of substance of sodium nitrate is 6mmol;

[0069] (2) Prepare a nitric acid solution with a concentration of 1mol / L and a 6mol / L potassium borohydride aqueous solution for later use;

[0070] (3) Take 3 mL of the sulfuric acid solution obtained in step (2) and slowly add it dropwise to the solution obtained in step (1). After stirring at room temperature for 20 minutes, slowly add 5 mL of the reducing agent solution obtained in step (2), and continue stirring at room temperature for 30 minutes;

[0071] (4) Add the precursor solution in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com