A method for electrosynthesizing 2,5-furandicarboxylic acid and 2,5-dimethyloltetrahydrofuran in pairs with a vanadium nitride-based catalyst

A technology of dimethyloltetrahydrofuran and vanadium nitride-based catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of low catalyst cost, complex production process, and high reaction efficiency, and achieve production The process is simple, the conversion rate of raw materials is high, and the selectivity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

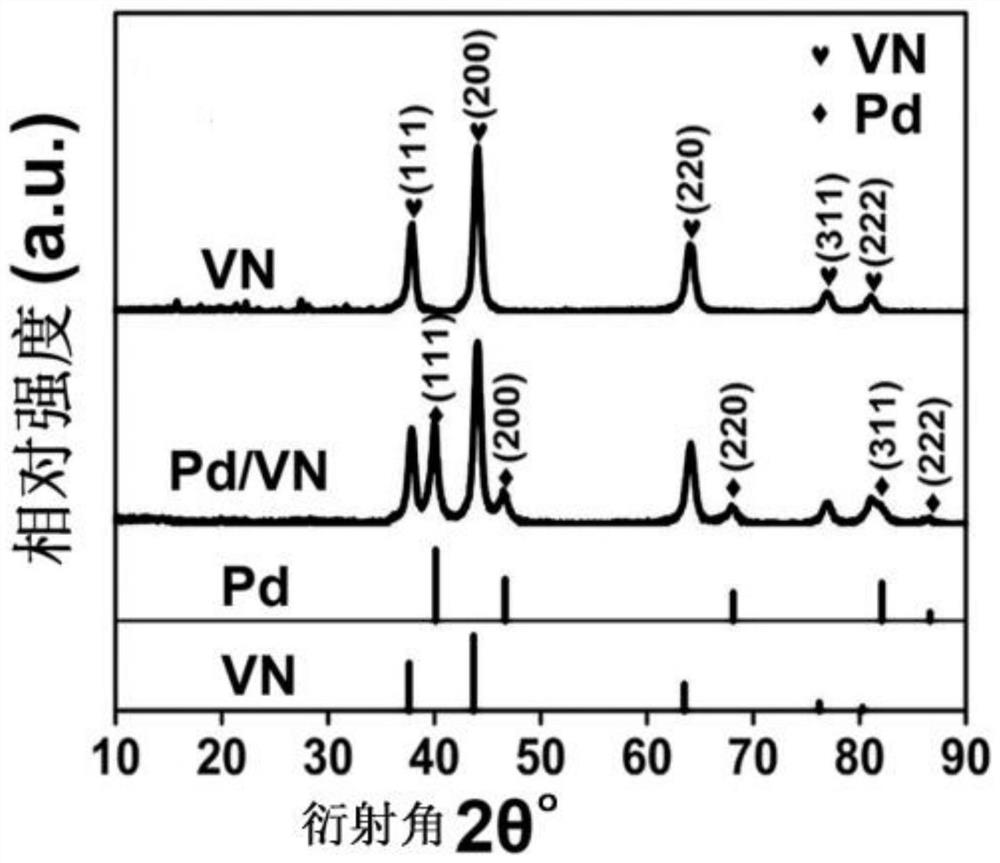

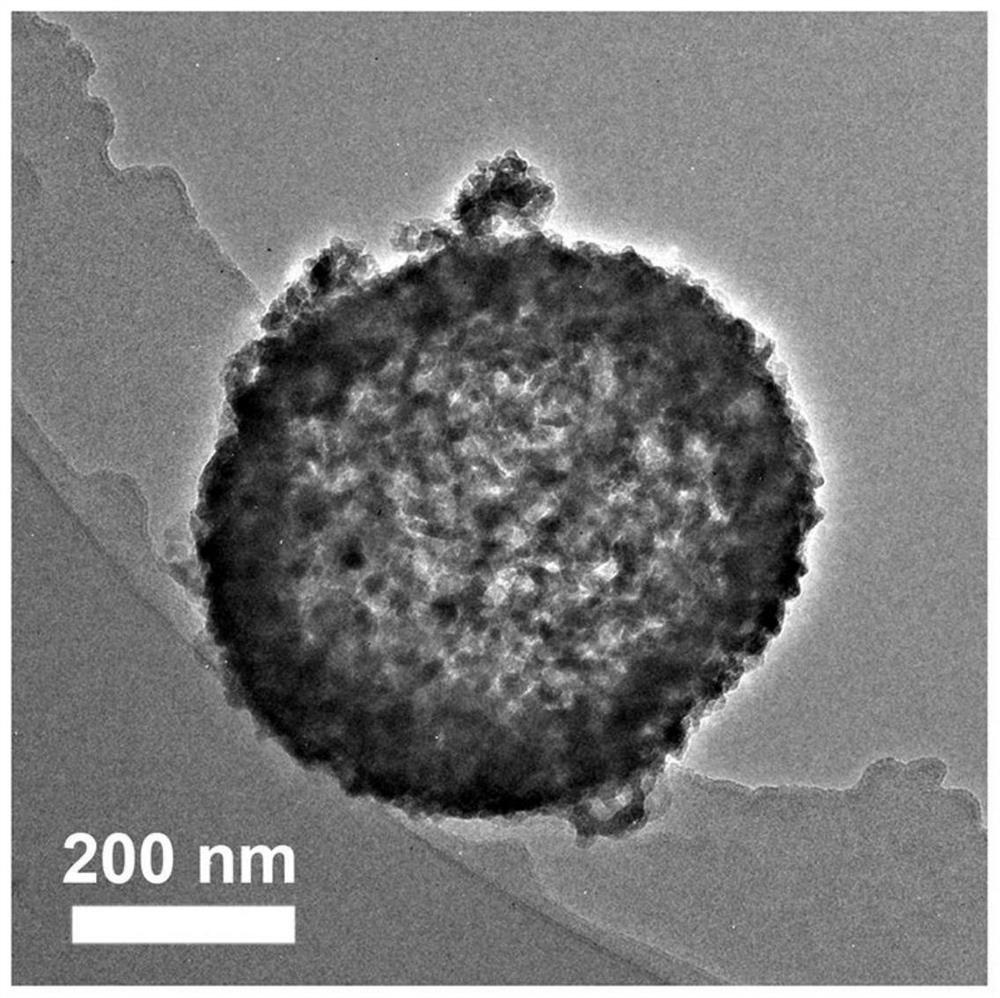

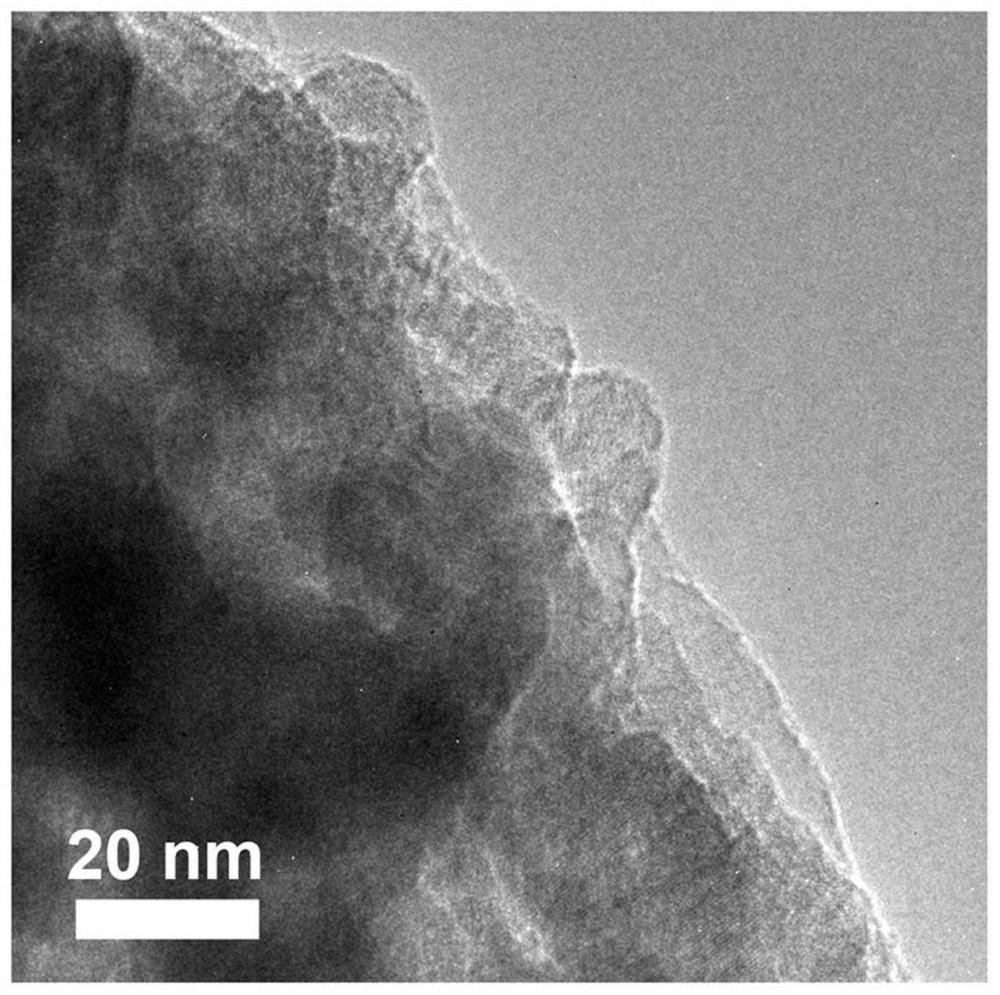

[0043] Embodiment 1: the synthesis of VN catalyst and 10%Pd / VN catalyst and its use in paired electrosynthesis system FDCA and DHMTHF

[0044] 1) Dissolve 234 mg of ammonium metavanadate in 40 mL of water, stir at room temperature for 30 min, and the amount of ammonium metavanadate added is 2 mmol;

[0045] 2) Prepare a hydrochloric acid solution with a concentration of 1 mol / L, and prepare an 8 mol / L aqueous solution of hydrazine hydrate for later use;

[0046] 3) Take 1 mL of the hydrochloric acid solution obtained in step 2) and slowly add it dropwise to the solution obtained in step 1). After stirring at room temperature for 10 min, slowly add 2 mL of the aqueous solution of hydrazine hydrate obtained in step 2) dropwise, and continue stirring at room temperature for 30 min. Obtain precursor solution;

[0047] 4) Move the precursor solution in step 3) into a hydrothermal kettle, and conduct a hydrothermal reaction at 160°C for 8 hours. After the reaction, cool to room tem...

Embodiment 2

[0062] Example 2: Synthesis of VN catalyst and its electrocatalytic oxidation of HMF to prepare FDCA

[0063] 1) Dissolve 176 mg of ammonium metavanadate in 40 mL of water, stir at room temperature for 30 min, and the amount of ammonium metavanadate added is 1.5 mmol;

[0064] 2) Prepare a hydrochloric acid solution with a concentration of 2 mol / L and a 5 mol / L aqueous solution of hydrazine hydrate for later use;

[0065] 3) Take 1 mL of the hydrochloric acid solution obtained in step 2) and slowly add it dropwise to the solution obtained in step 1). After stirring at room temperature for 10 minutes, slowly add 1 mL of the aqueous solution of hydrazine hydrate obtained in step 2) dropwise, and continue stirring for 30 minutes at room temperature. Obtain precursor solution;

[0066] 4) Transfer the precursor solution in step 3) into a hydrothermal kettle, and conduct a hydrothermal reaction at 120°C for 12 hours. After the reaction, cool to room temperature and filter with suc...

Embodiment 3

[0074] Example 3: Synthesis of 10% Pd / VN catalyst and its electrocatalytic reduction of HMF to DHMTHF

[0075] 1) Dissolve 351 mg of ammonium metavanadate in 40 mL of water, stir at room temperature for 30 min, and the amount of ammonium metavanadate added is 3 mmol;

[0076] 2) Prepare a hydrochloric acid solution with a concentration of 1 mol / L and a 5 mol / L aqueous solution of hydrazine hydrate for later use;

[0077] 3) Take 3 mL of the hydrochloric acid solution obtained in step 2) and slowly add it dropwise to the solution obtained in step 1). After stirring at room temperature for 10 min, slowly add 4 mL of the aqueous solution of hydrazine hydrate obtained in step 2) dropwise, and continue stirring at room temperature for 30 min. Obtain precursor solution;

[0078] 4) Transfer the precursor solution in step 3) into a hydrothermal kettle, and conduct a hydrothermal reaction at 180°C for 5 hours. After the reaction, cool to room temperature and filter with suction. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com