A kind of composite platinum nanoparticle and metal nitride material catalyst and its preparation method and application

A platinum nanoparticle, nitride technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as unfavorable industrial large-scale production, polymerization of phenolic compounds, catalyst deactivation, etc. Achieve the effect of low cost, mild conditions and high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

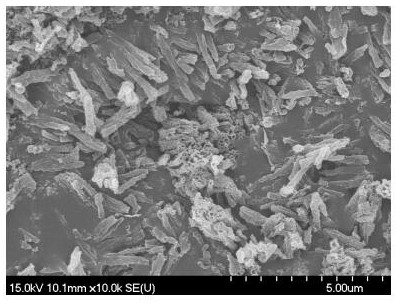

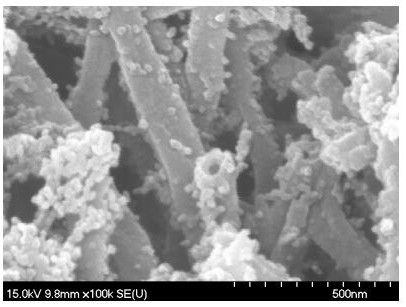

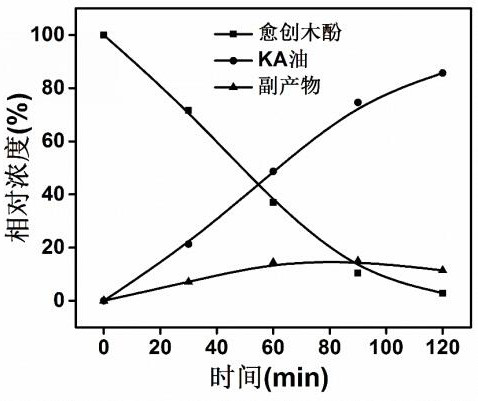

[0033] Example 1: Synthesis of Pt / CoN@BCN catalyst and its electrocatalytic reduction of guaiacol to prepare KA oil and its derivatives

[0034] (1) Dissolve 0.15 g of boric acid, 5 g of urea, and 0.5 g of polyethylene glycol into 50 mL of water and disperse uniformly by ultrasonic, then add 0.065 g of cobalt phthalocyanine, stir at room temperature for 1 hour, and then transfer the obtained solution to an oven , dried at 120°C for 14 hours to obtain a solid mixture;

[0035] (2) Place the solid mixture obtained in step (1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under an argon atmosphere, and calcinate at 900°C for 4 hours to obtain a catalyst carrier (The catalyst support is marked as CoNx@BCN);

[0036] (3) Take 20 mg of the catalyst carrier CoNx@BCN obtained in step (2) and 5 mg of chloroplatinic acid into 10 mL of deionized water, and ultrasonically mix the solution for 1 hour to obtain a solution A; dissolve 8 mg of sod...

Embodiment 2

[0042] Example 2: Synthesis of Pt / FeNx@BCN catalyst and its electrocatalytic reduction of guaiacol to prepare KA oil and its derivatives

[0043] (1) Dissolve 0.15 g of boric acid, 5 g of urea, and 0.5 g of polyethylene glycol into 50 mL of water for ultrasonic dispersion, then add 0.060 g of iron phthalocyanine, stir at room temperature for 1 hour, and then transfer the resulting solution to an oven , dried at 100°C for 12 hours to obtain a solid mixture;

[0044] (2) Place the solid mixture obtained in step (1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under an argon atmosphere, and calcinate at 900°C for 4 hours to obtain a catalyst carrier (The catalyst support is marked as FeNx@BCN);

[0045] (3) Take 20 mg of the catalyst carrier FeNx@BCN obtained in step (2) and 5 mg of chloroplatinic acid into 10 mL of deionized water, and ultrasonically mix the solution for 1 hour to obtain A solution; dissolve 8 mg of sodium borohyd...

Embodiment 3

[0050] Example 3: Synthesis of Pt / NiNx@BCN catalyst and its electrocatalytic reduction of guaiacol to prepare KA oil and its derivatives

[0051] (1) Dissolve 0.15 g of boric acid, 5 g of urea, and 0.5 g of polyethylene glycol in 50 mL of water and disperse uniformly by ultrasonication, then add 0.068 g of nickel phthalocyanine, stir at room temperature for 1 hour, and then transfer the obtained solution to In an oven, dry at 100°C for 8 hours to obtain a solid mixture;

[0052] (2) Place the solid mixture obtained in step (1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under an argon atmosphere, and calcinate at 900°C for 4 hours to obtain a catalyst carrier (The catalyst support is marked as NiNx@BCN);

[0053] (3) Take 20 mg of the catalyst carrier NiNx@BCN obtained in step (2) and 5 mg of chloroplatinic acid into 10 mL of deionized water, and ultrasonically mix the solution for 1 hour to obtain A solution; dissolve 8 mg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com