Energy saving method for circulating water system

A circulating water system, high-efficiency and energy-saving technology, applied in non-variable-capacity pumps, pump devices, machines/engines, etc., can solve the problems of increasing internal leakage loss, improper operation and maintenance management, and increasing power loss, and improve operating efficiency. , Complete energy saving effect, eliminate the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

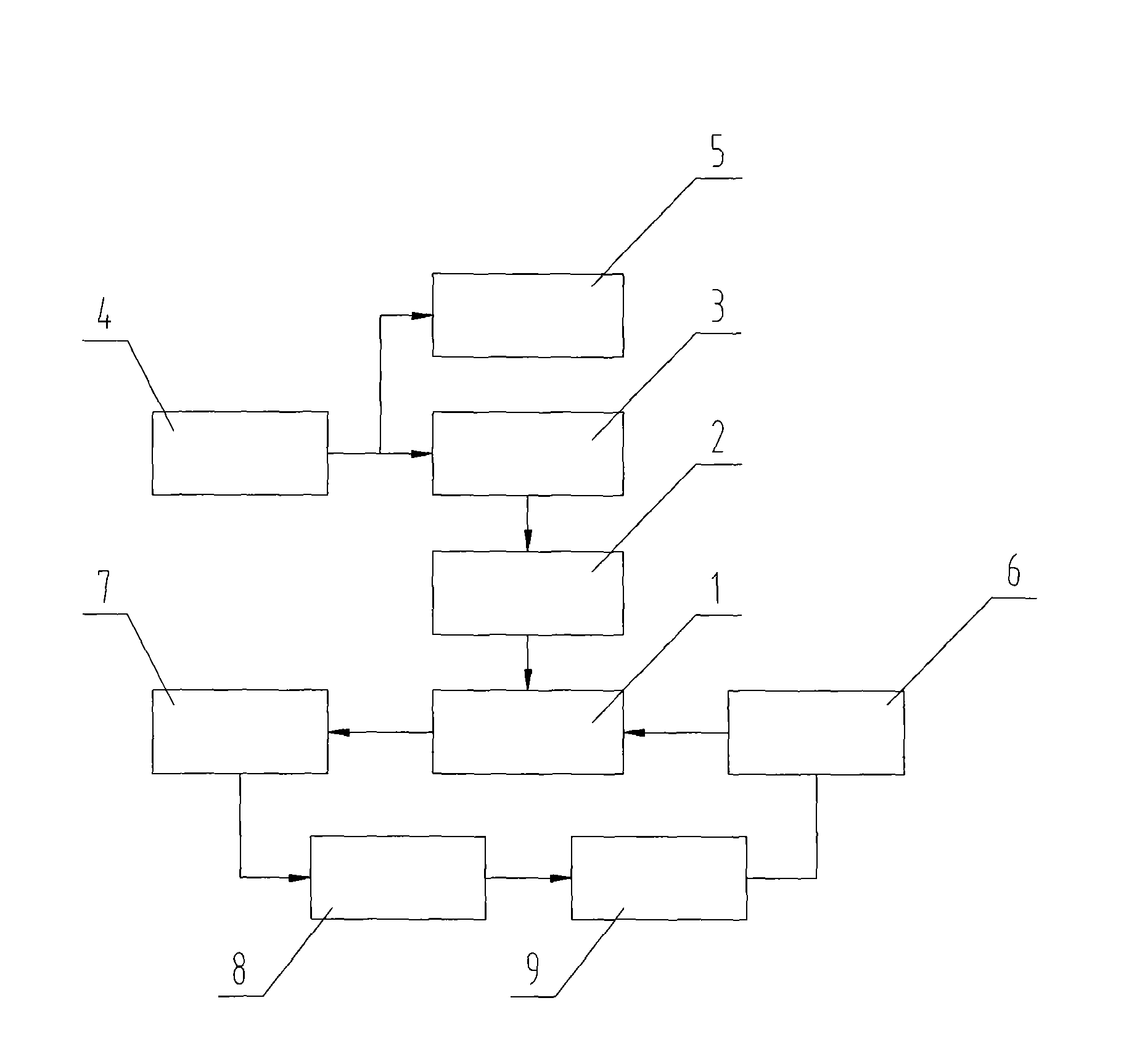

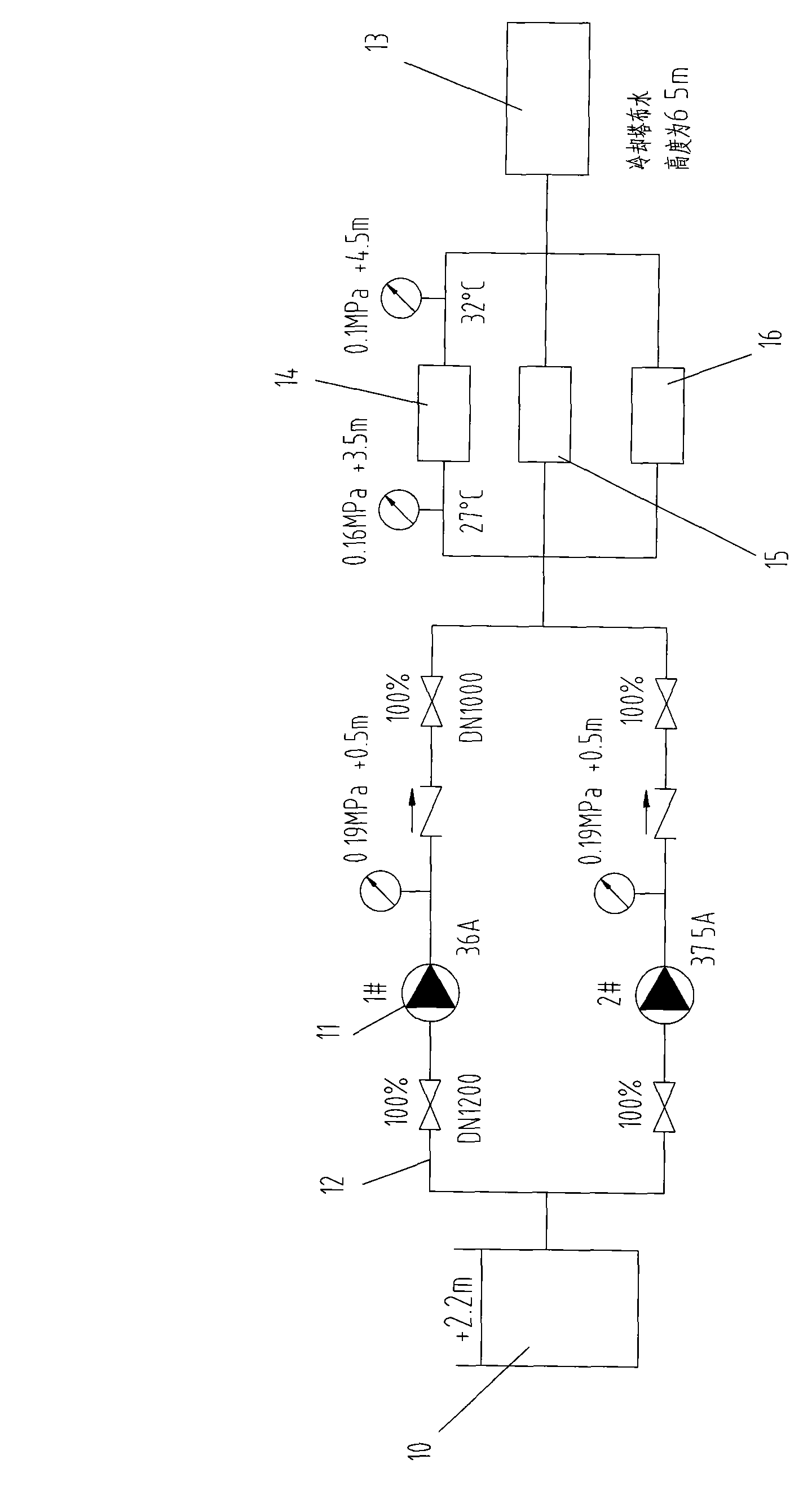

[0047] see figure 2 , the circulating water system of a thermal power plant includes water pump unit 11, water inlet and outlet pipeline 12, water inlet pool 10, cooling tower 13, condensing steam 14, air cooler 15, oil cooler 16, etc., and its energy-saving transformation includes three steps:

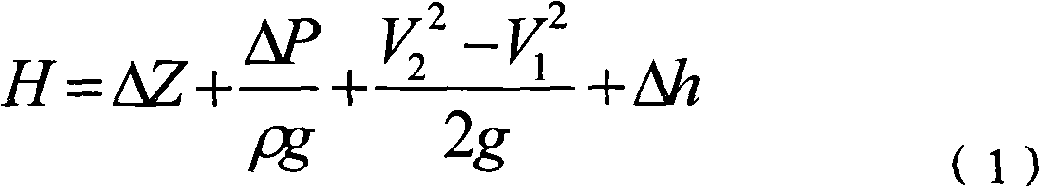

[0048] First, use pressure gauges, flow meters, power meters, thermometers, tape measures and other tools to actually measure the on-site data of the circulating water system. The water inlet level is +2.2m, the outlet pressure of the pump is 0.19Mpa, the surface height is +0.5m, the temperature difference between the inlet and outlet water is 5°C, the water distribution height of the cooling tower 13 is +6.5m, and the system flow rate is 3.56m 3 / s. The current of the two water pumps is 36A and 37.5A respectively, the voltage is 10.2KV, the motor p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com