Preparation method of cesium carbonate

A technology of cesium carbonate and sulfuric acid, applied in chemical instruments and methods, rubidium/cesium/francium compounds, alkali metal compounds, etc., can solve the problems of insurmountable safety problems, large labor time consumption, waste of cost and energy consumption, etc. The effect of eliminating the generation of intermediate toxic substances, shortening the production cycle, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

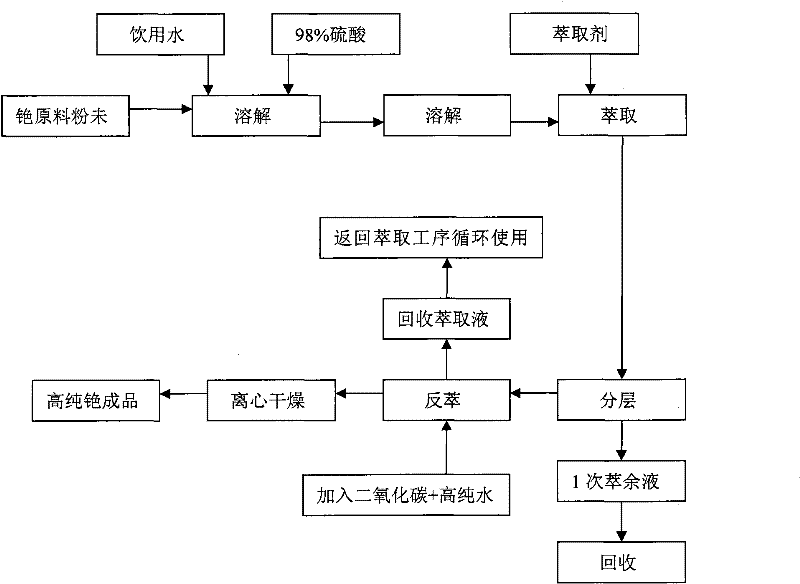

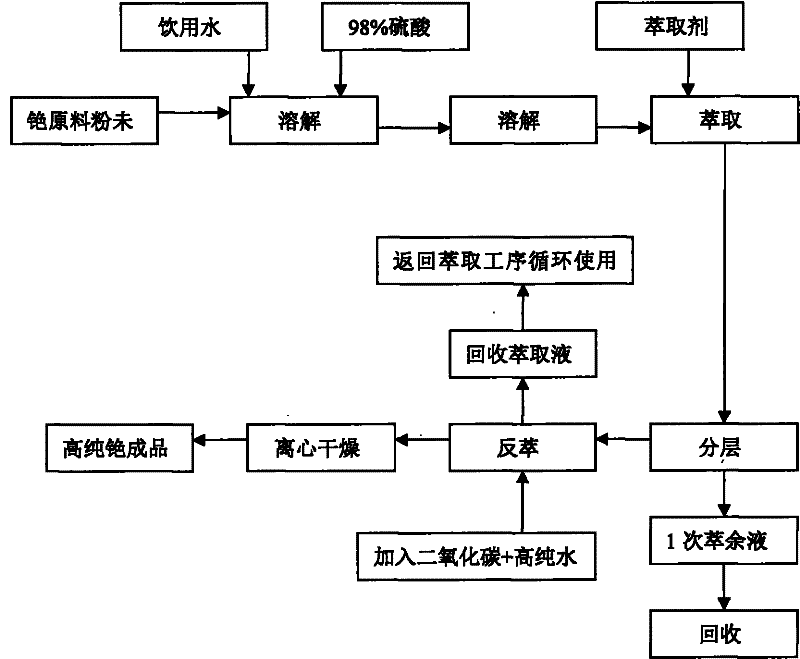

[0021] Below in conjunction with accompanying drawing, the preparation method of cesium carbonate is described in detail:

[0022] Step 1, pre-treatment of cesium powder Add cesium powder into well-proportioned water and sulfuric acid and soak in the reactor. The raw solution is leached from the mixture, and other alkaline ions are leached at the same time: Rb, K, Na, Li, Fe, Al, Si, Cl -1 , CO 3 -2 , soaking for 4 to 6 hours can leach most of the cesium ions;

[0023] Step 2, adding the prepared lye to the stock solution obtained in step 1, adjusting the pH of the stock solution to 11-13 o'clock, the prepared lye is sodium hydroxide or calcium oxide or calcium hydroxide or sodium carbonate;

[0024] Step 3, extraction Add extractant T-BAMBP to the liquid obtained in step 2 to extract, the amount of extractant added is 1mol / L extractant: stock solution=4:3, the stock solution reacts with the high-efficiency extractant under the condition that the pH is 11~13 , will react w...

Embodiment 1

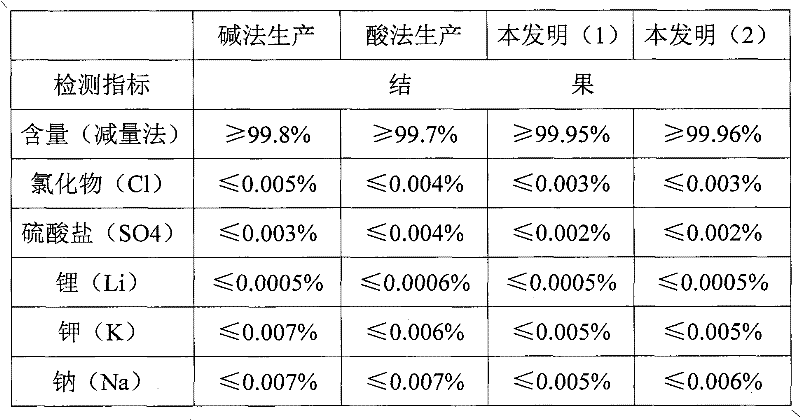

[0029] Example 1 According to the proportioning cesium powder: 98% sulfuric acid: water = 1: 0.75: 2 ingredients, reactor temperature 85 ° C, soaking time 6 hours, then add lye sodium hydroxide, adjust to pH 13, add extraction agent T- BAMBP is extracted, and back-extracted after layering, adding carbon dioxide with a purity of 99.99% of 150g / L and 1 / 6 of the high-purity water above 15Ω to obtain a cesium carbonate solution, and then centrifuged and dried at a speed of 1200r / m for 20min at 600°C Dry to obtain solid cesium carbonate. Its technical index is listed in the following table the present invention (1).

Embodiment 2

[0030] Example 2 According to the proportion of cesium powder: 98% sulfuric acid: water = 1: 0.8: 1.9 ingredients, the reactor temperature is 100 ° C, soaking time is 4 hours, then add lye calcium hydroxide, adjust to pH 11, add extractant T- BAMBP extracts, back-extraction after layering adds 1 / 8 of the high-purity water upper layer extraction liquid that purity is 99.99% carbon dioxide 160g / L and 15Ω above, and subsequent process is identical with embodiment. Its technical index is listed in the following table the present invention (2).

[0031] See the table below for the main quality indicators prepared by the preparation method of the present invention and the traditional method:

[0032]

[0033]

[0034] Economic and social benefits:

[0035]At present, my country's economic construction is in a period of transformation, from the traditional industrial economy to the green economy and low-carbon economy. The traditional industrial economy is an economy characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com