Controllable integral rotary solid-state fermentation tank

A solid-state fermenter and rotary technology, applied in the field of controllable integral rotary solid-state fermenter, can solve the problems of easy destruction of microbial structure, low degree of automation, labor and material resources, etc., to improve fermentation efficiency, reduce production costs, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

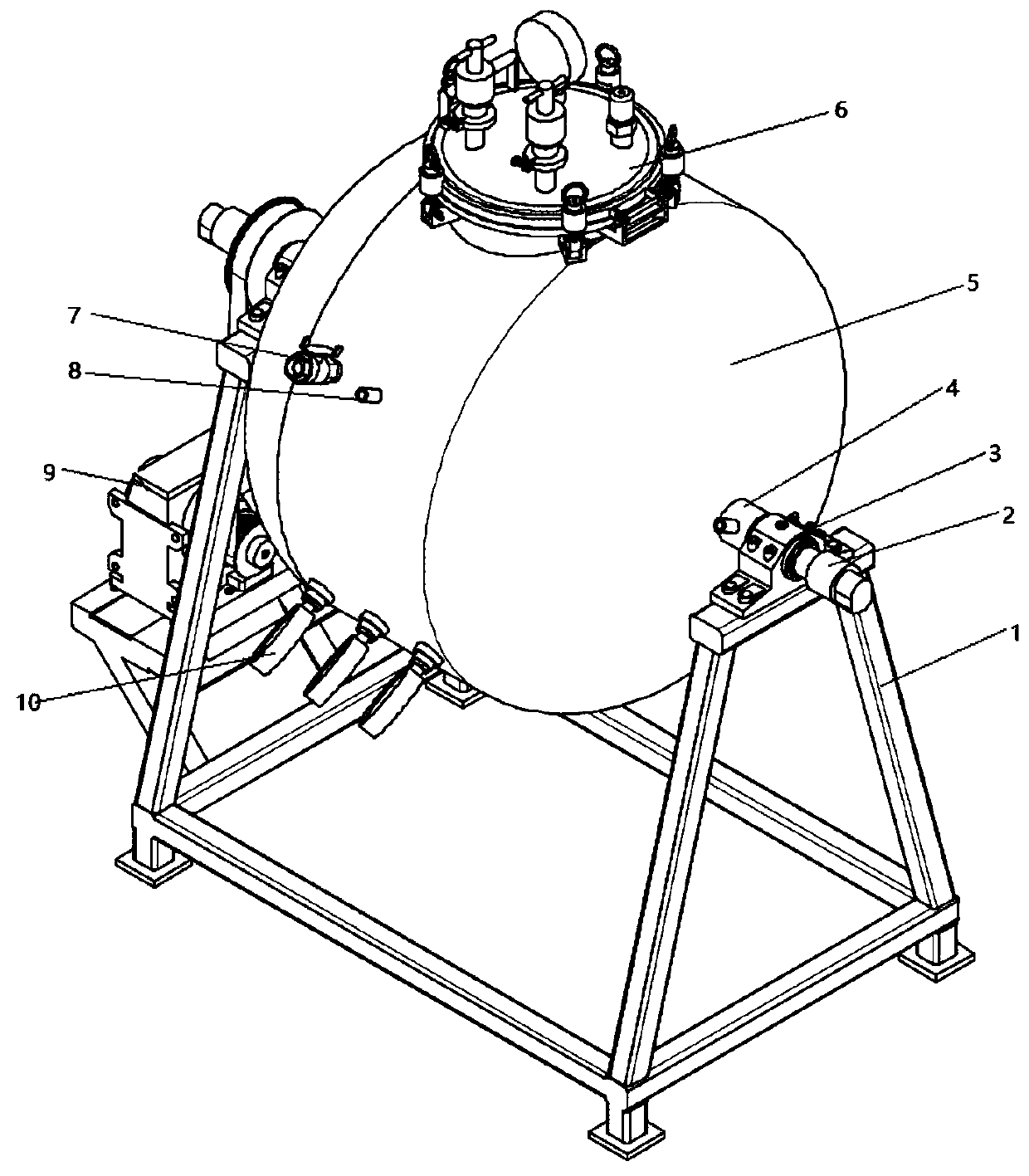

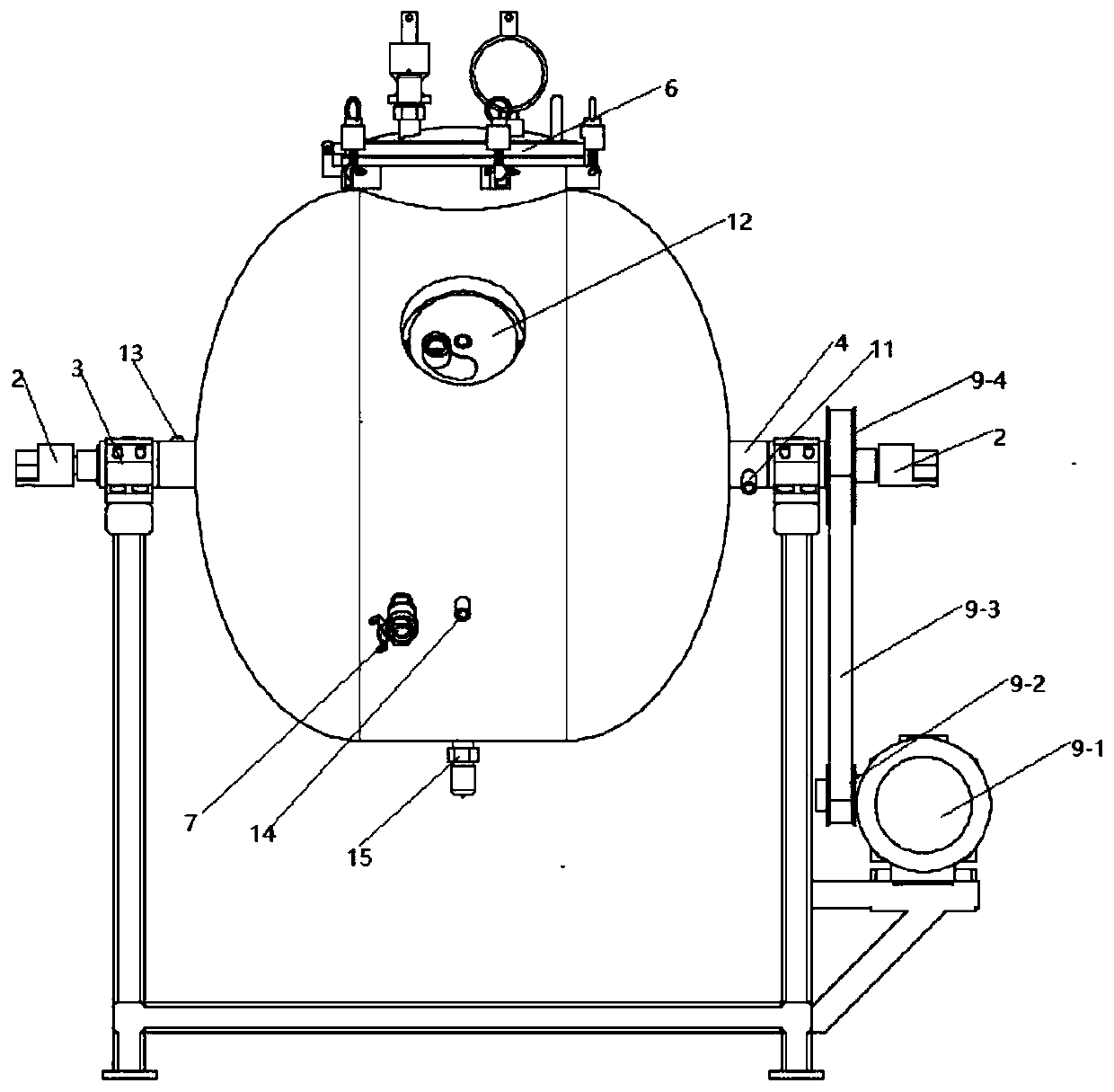

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] Such as Figure 1~3 As shown, a controllable overall rotating solid-state fermentation tank includes a frame 1, and the top of the frame 1 is fixedly connected with two left and right hollow rotating shafts 4 through bearing seats 3 respectively, and the two hollow rotating shafts 4 are respectively provided with water inlets 13 and water outlet 11, and each end is connected with a rotary joint 2, wherein a hollow rotating shaft 4 is connected with a driving device 9, and the driving device 9 includes a large pulley 9-4 connected with the hollow rotating shaft 4, and the large pulley 9- 4 is connected with small pulley 9-2 by belt 9-3, and small pulley 9-2 is connected to variable frequency motor 9-1 again;

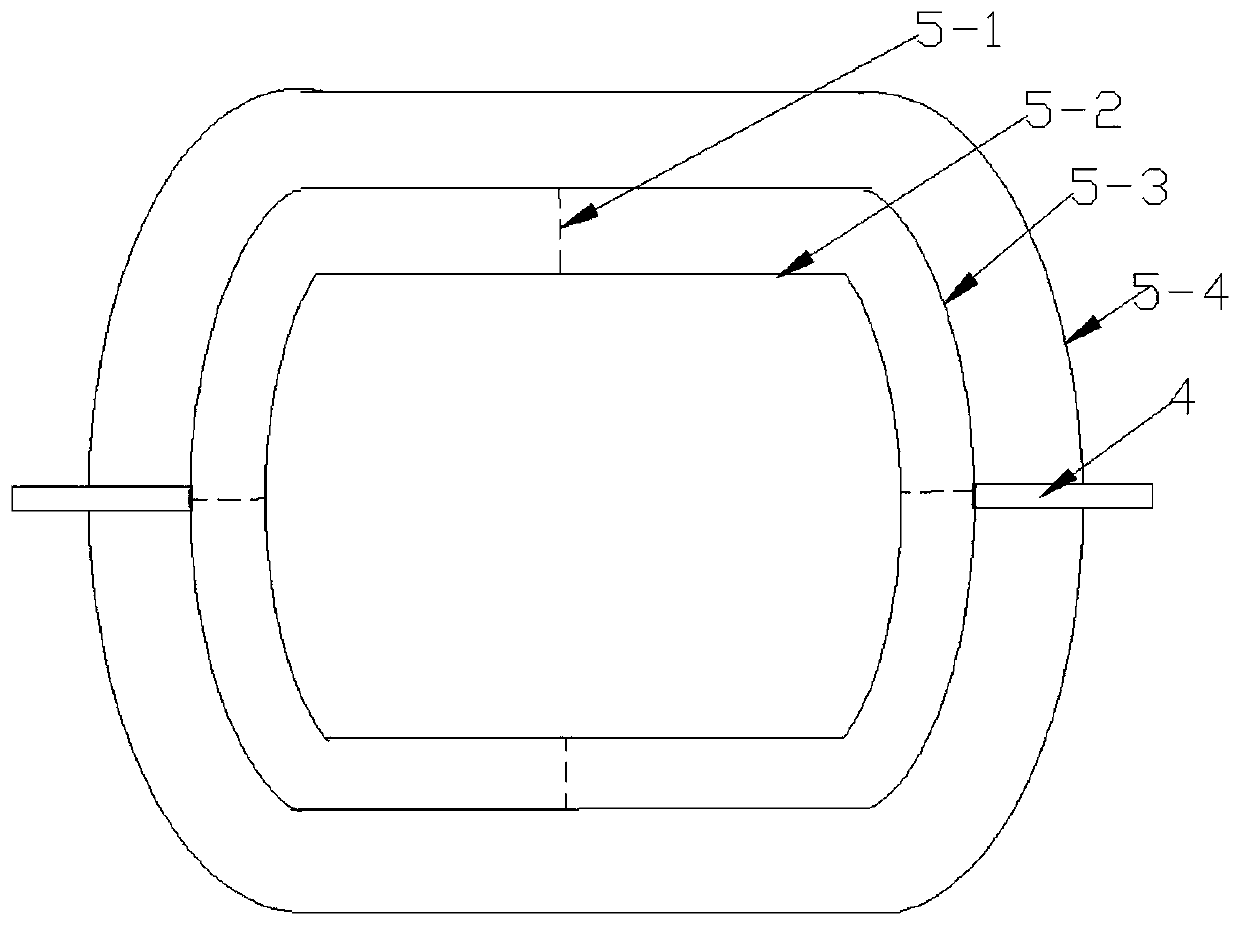

[0032] A cylindrical tank body 5 is fixedly connected between the two hollow rotating shafts 4, and the tank body 5 includes an outer shell 5-4, an intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com